High grade cobalt sulfonate slag and production process thereof

A high-grade technology of cobalt xanthate, applied in the direction of improving process efficiency, etc., can solve the problems of reducing the amount of sodium ethyl sulfonate, expensive oxidant, and expensive copper sulfate, so as to reduce energy consumption, high promotion value, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0057] The specific embodiments of the present invention are as follows, those skilled in the art should understand that the zinc hydrometallurgy process is only a schematic illustration, those skilled in the art can further clearly understand through the specific embodiments of the present invention given below the present invention, but they are not limitations of the present invention.

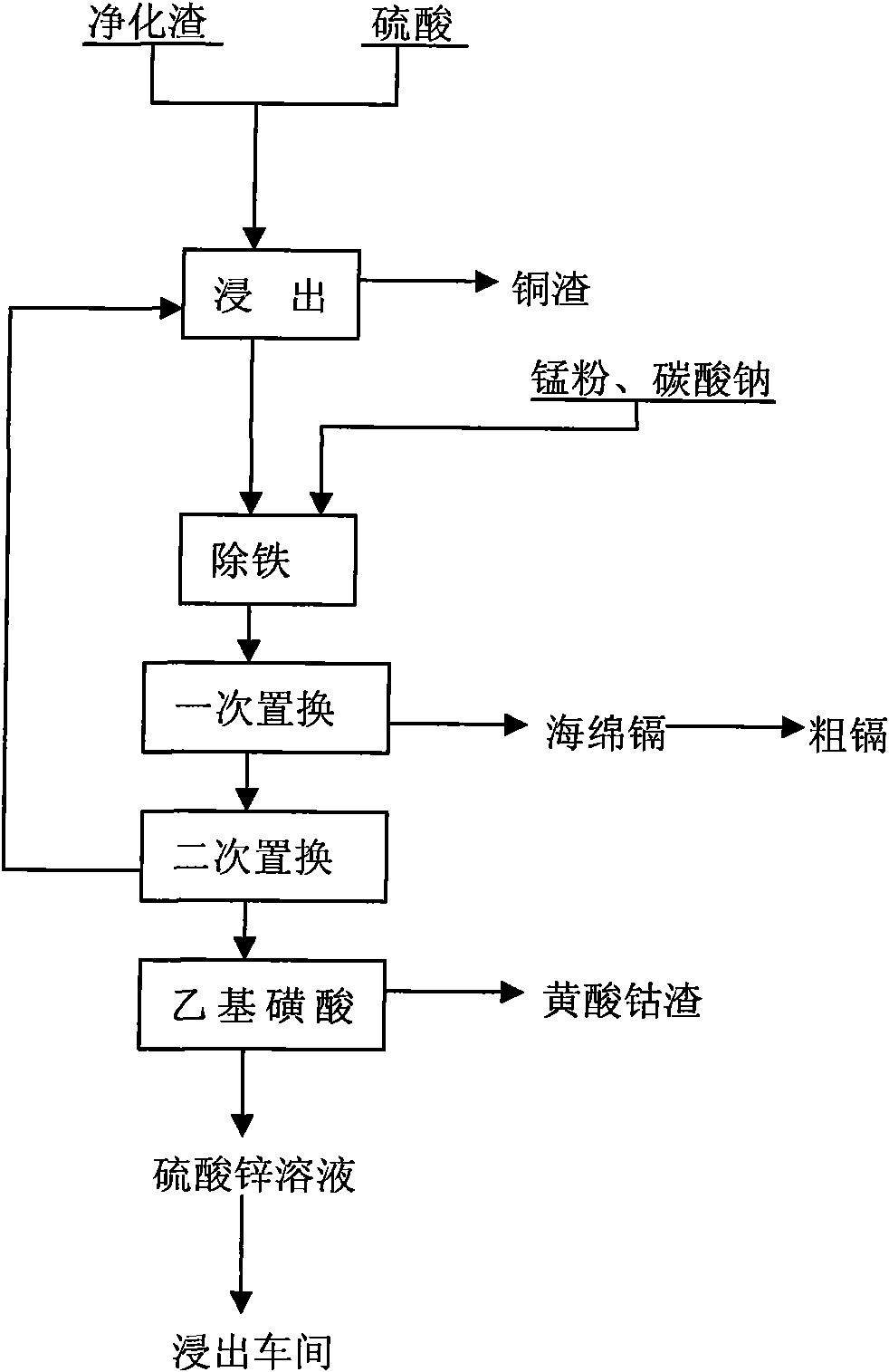

[0058] Hydrometallurgy zinc process:

[0059] 1. Purification slag leaching

[0060] 1. Process principle

[0061] The principle of purification slag leaching is to use the zinc, cadmium, cobalt of the purification slag to react with sulfuric acid to enter the solution, while the copper element does not react with sulfuric acid and remains in the slag, so as to realize the separation of copper and other valuable metals.

[0062] main chemical reaction

[0063] Cd+H 2 SO 4 =CdSO 4 +H 2 ↑ (1)

[0064] CdO+H 2 SO 4 =CdSO 4 +H 2 O (2)

[0065] Zn+H 2 SO 4 =ZnSO 4 +H 2 ↑ (3)

...

Embodiment 2

[0116] Similar to other steps of embodiment 1, wherein for the technology of reclaiming cobalt in the hydrometallurgy process, ammonium persulfate is used as oxidant sodium ethyl sulfonate to reclaim cobalt:

[0117] The technological conditions are: temperature 35-40°C; initial pH 5.0-5.2; sodium ethylsulfonate: ammonium persulfate: cobalt = (9-12): (4-5): (0.5-2); Time 20-30 minutes; reaction time 0.5-1.5 hours,

[0118] 3. Operating procedures

[0119] 3.1 Calculate the amount of cobalt removal agent according to the total amount of cobalt in the solution, the preparation ratio of the agent: sodium ethylsulfonate: ammonium persulfate: cobalt = (9-12): (4-5): (0.5-2),

[0120] 3.2 Prepare sodium ethyl sulfonate as a 10% solution, and ammonium persulfate as a solution for later use.

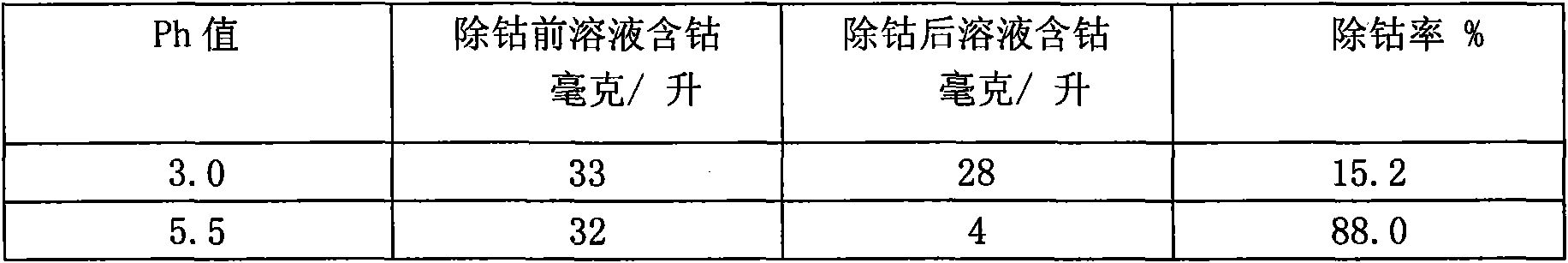

[0121] 3.3 Drill 40-45m into the cobalt removal tank 3 After the second stage of cadmium removal, control the pH of the initial acid to be greater than 5.0. When the acidity is too high, add ...

Embodiment 3

[0125] Similar to other steps of embodiment 1, wherein for the technique of reclaiming cobalt in the hydrometallurgy process is: ammonium persulfate is used as oxidant sodium ethyl sulfonate to remove cobalt, and its technological condition is:

[0126] Temperature 38°C; PH (beginning) 5.1; sodium ethylsulfonate: ammonium persulfate: cobalt = 12:4.8:0.9; dosing time 29 minutes; reaction time 1.1 hours.

[0127] Operation steps include

[0128] 3.1 Calculate the amount of cobalt removal agent according to the total amount of cobalt in the solution. The preparation ratio of the agent is: sodium ethylsulfonate: ammonium persulfate: cobalt = 12:4.8:0.9.

[0129] 3.2 Prepare sodium ethylsulfonate as a 10% solution and ammonium persulfate as a solution for later use.

[0130] 3.3 Drill 40-45m into the cobalt removal tank 3 After the second stage of cadmium removal, control the pH of the initial acid to 5.1. When the acidity is too high, add sodium hydroxide to adjust the pH to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com