Copper alloy material with high strength and conductivity and manufacturing method of copper alloy material

A manufacturing method and copper alloy technology, applied in the field of high-strength and high-conductivity copper alloy materials and its manufacturing, can solve problems such as high production costs, hazards, and environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] The mass percent of alloy elements is Ni: 2.50%, Si: 0.50%, Cr: 0.53%, Al: 0.15%, Be: 0.06%, and the balance is copper and unavoidable impurities. The implementation process is as follows: smelting in an intermediate frequency induction furnace and casting into ingots; thermal deformation within the temperature range of 850 ° C to 700 ° C, and the deformation amount is 70%; solid solution treatment at 900 ° C, and then cooled in water; cold deformation treatment, the deformation amount is 25%; the cold deformed blank is subjected to aging treatment at 500°C.

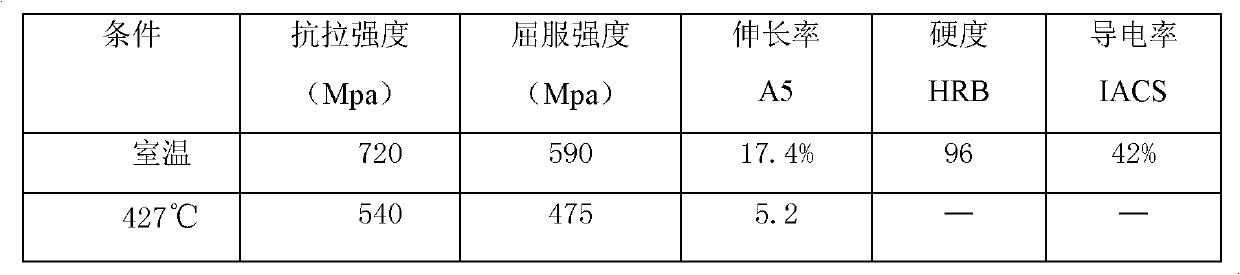

[0017] The performance index of the alloy material is:

[0018]

Embodiment 2

[0020] The mass percent of alloy elements is Ni: 2.87%, Si: 0.39%, Cr: 0.30%, Al: 0.27%, Be: 0.10%, and the balance is copper and unavoidable impurities. The implementation process is as follows: smelting in an intermediate frequency induction furnace and casting into ingots; thermal deformation within the temperature range of 850°C to 700°C, the deformation amount is 50%; solid solution treatment at 870°C, and then cooled in water; cold deformation treatment, the deformation amount It is 45%; the blank after cold deformation is subjected to aging treatment at 460°C.

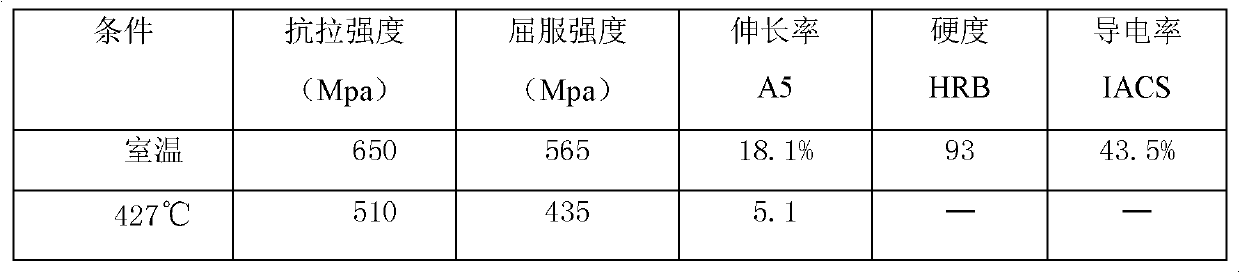

[0021] The performance index of the alloy material is:

[0022]

Embodiment 3

[0024] The mass percent of alloy elements is Ni: 2.33%, Si: 0.56%, Cr: 0.54%, Al: 0.11%, Be: 0.08%, and the balance is copper and unavoidable impurities. The implementation process is as follows: smelting in an intermediate frequency induction furnace and casting into ingots; thermal deformation within the temperature range of 850°C to 700°C, with a deformation amount of 5%; solid solution treatment at 920°C, and then cooling in water; cold deformation treatment, the deformation amount is 45%; the cold deformed blank is subjected to aging treatment at 510°C.

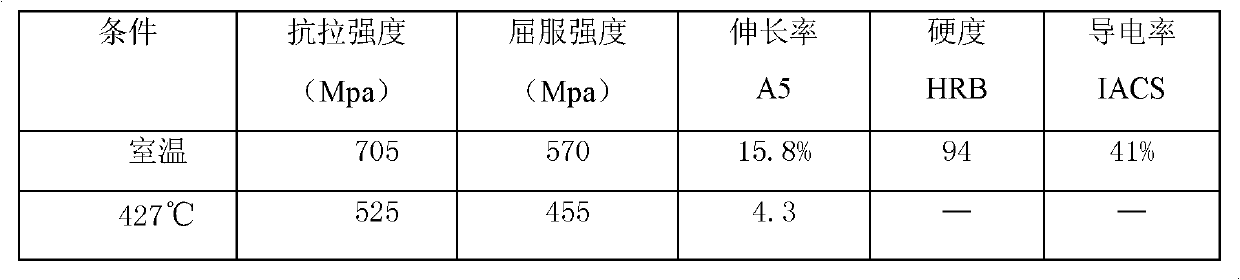

[0025] The performance index of the alloy material is:

[0026]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com