Low energy consumption, low emission, coal quality guaranteed and safe drying method and device for chemical feed coal

A technology for chemical raw materials and drying devices, applied in the field of coal chemical industry, can solve the problems of multi-fine coal powder, large environmental pollution, hidden dangers of production management safety, etc., and achieve the effects of high comprehensive utilization rate, improved working environment, and obvious energy saving effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0021] The particle size of the raw coal in step A is 0.2-10mm, and the preheating temperature is 75-85°C.

[0022] The drying device described in step B is a drum drying device, so that the coal particles can be in a tumbling state, and the contact efficiency with the superheated steam is improved.

[0023] The degree of superheat of the superheated steam in step B is >20%, and the dried coal particles are sent to the coal storage bunker 10 after being sieved.

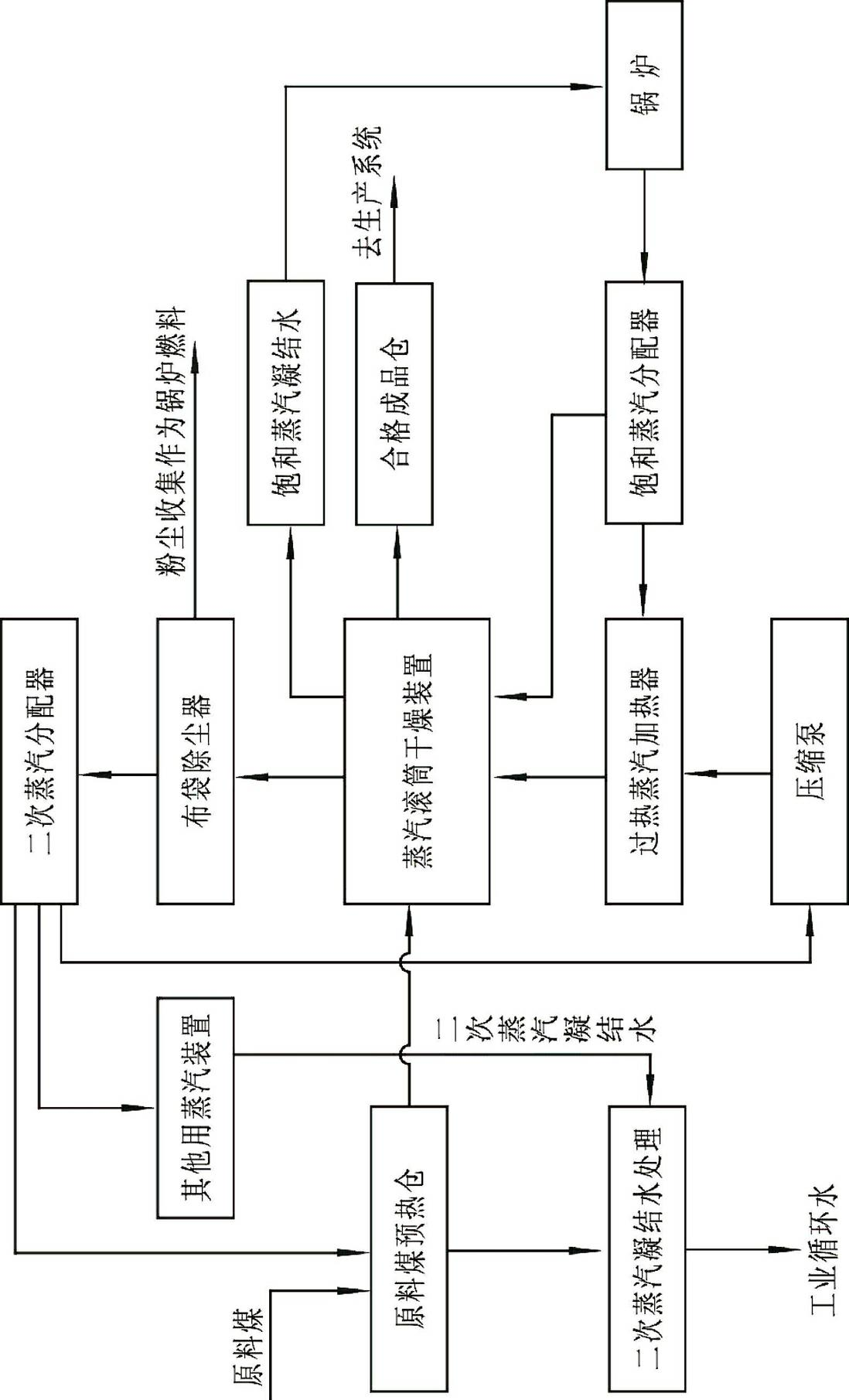

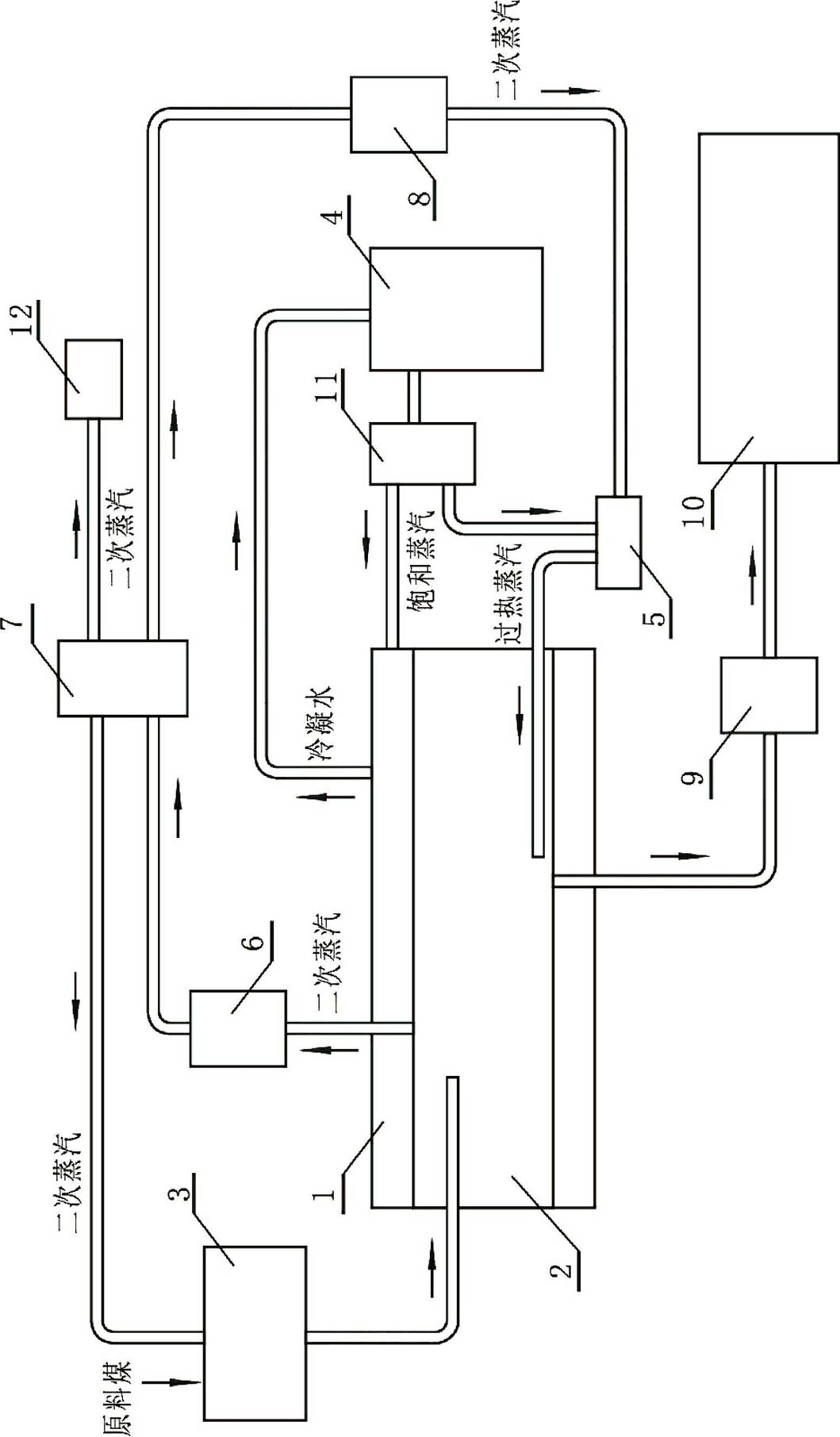

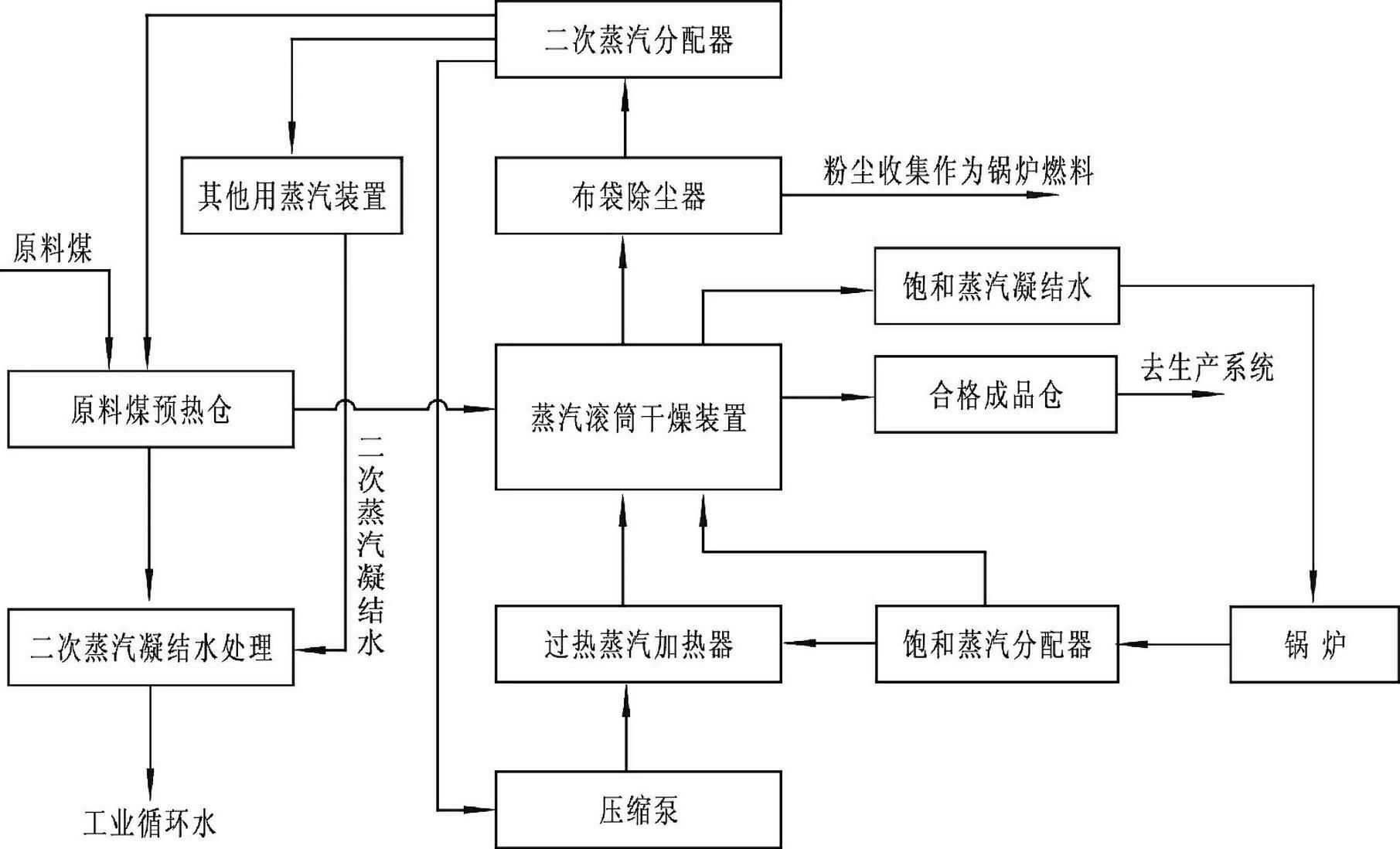

[0024] The device of the present invention includes a coal preheating device 3, a drying device, a steam boiler 4, and a superheated steam generator 5, and the coal preheating device 3 is technologically connected with the drying device; the drying device includes an indirect heating layer 1 and a drying area 2, The steam boiler 4 is respectively connected to the indirect heating layer 1 and the superheated steam generator 5 through the saturated steam distributor 11, and the steam outlet of the superheated steam gene...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com