Immunofluorescence test strip module for rapidly and quantitatively testing microalbumin, test card module made of same and preparation method thereof

A microalbumin and quantitative detection technology, applied in the field of medical testing, can solve the problems of false positives of markers, limit the application scope of immunochromatography technology, false negatives, etc., and achieve reliable and stable specificity, low detection cost, and simple operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

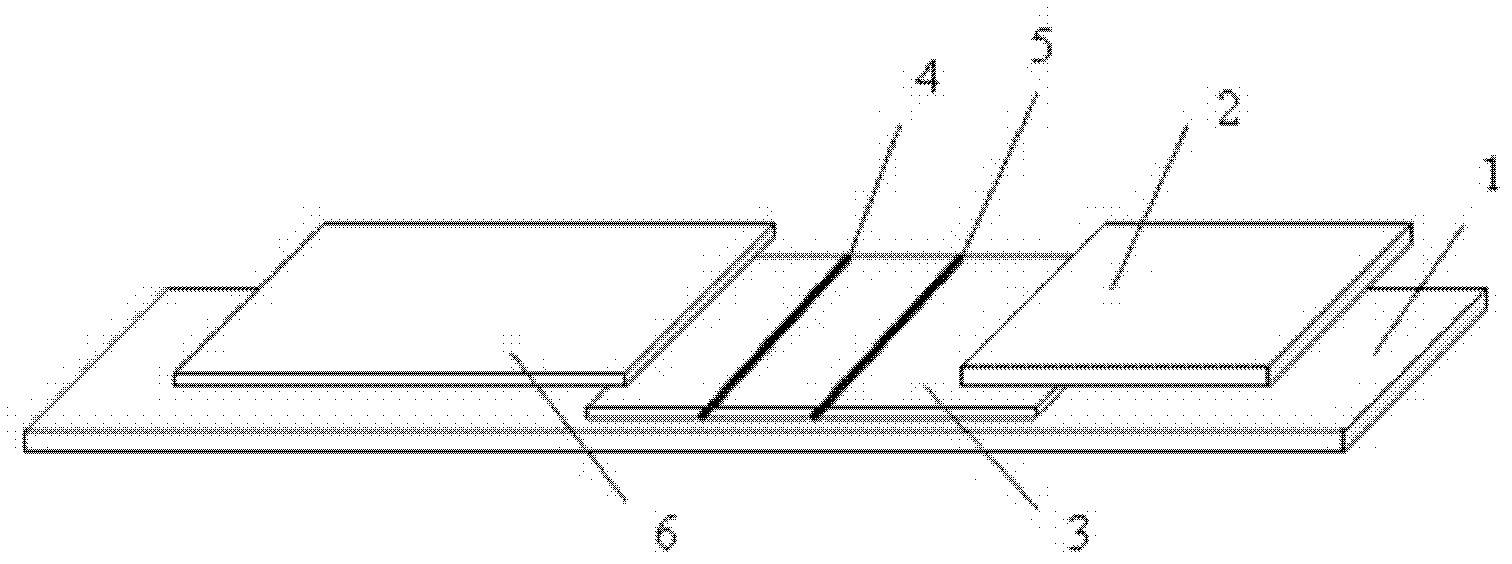

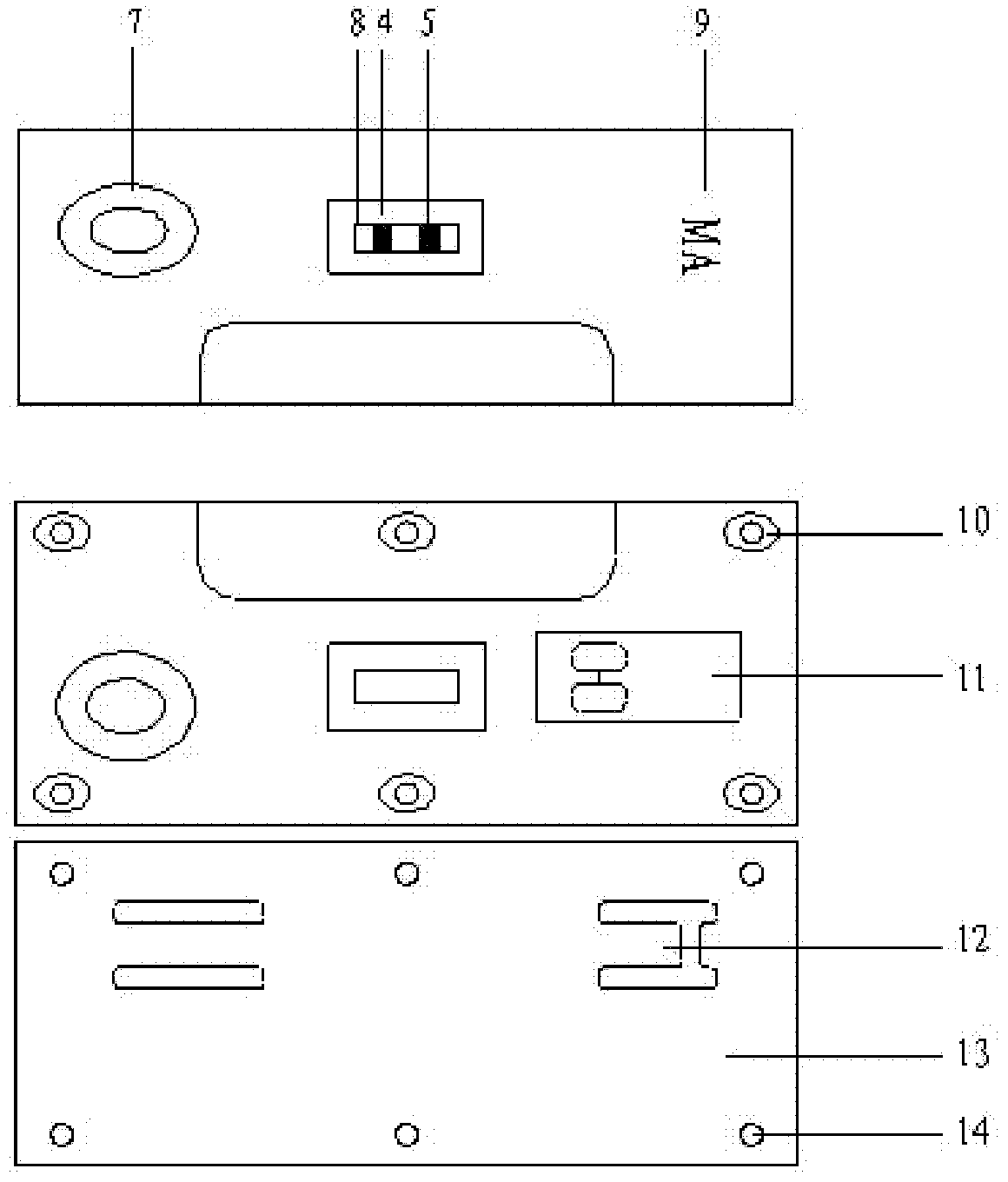

[0060] see figure 1 As shown, an immunofluorescence test strip assembly for rapid quantitative detection of microalbumin (MA) based on platinum porphyrin luminescence technology of the present invention comprises a test strip and a platinum porphyrin independently packaged and used in conjunction with the test strip. morpholino-labeled specific antibody 15. The test strip includes a substrate 1 , a coated analysis film 3 adhered to the middle of the substrate 1 , a water absorbing pad 2 and a sample pad 6 located at both ends of the coated analysis film 3 and overlapping it by 1-2 mm. The coating analysis membrane 3 is provided with a detection line 4 and a quality control line 5 formed by spray printing with a film sprayer. The specific antibody coated on the detection line 4 is anti-microalbumin monoclonal antibody, and the quality control line 5 is coated with The specific antibody is a rabbit IgG antibody. The platinum-porphyrin-labeled specific antibodies were anti-micr...

Embodiment 2

[0101] The preparation method of the present embodiment is basically the same as that of Example 1, the difference is:

[0102] In step 2, the method for preparing the detection line coating buffer is: dilute with 20mM pH7.6 phosphate buffer to make the concentration of the anti-microalbumin monoclonal antibody containing 1.0% methanol, 1.5% sucrose, and 0.6% bovine serum albumin to 1 mg / ml. Preparation of quality control line coating buffer: dilute with 50mM pH7.6 phosphate buffer to make the concentration of rabbit IgG antibody containing 0.7% methanol and 0.5% bovine serum albumin reach 0.5mg / ml. Preparation of the coating film: debug the film spraying machine, the film liquid volume is 25ul / 40cm, the machine scribes, the capture line and the quality control line are separated by 5mm, the scribe line is fine and uniform, and it is placed in a vacuum oven at 25°C-37°C for 1.5 hours. The bag is sealed for later use.

Embodiment 3

[0104] The preparation method of the present embodiment is basically the same as that of Example 1, the difference is:

[0105] In step 3, the anti-microalbumin monoclonal antibody 1 and the anti-rabbit IgG antibody were diluted to 1 mg / ml with 0.1 M sodium bicarbonate solution respectively, and 5 ml of the antibody solution was taken respectively, and 40 mg of the fluorescent material platinum porphyrin solution was added respectively, Stir well, incubate at room temperature for 1.5 hours, and mix once every 15 minutes; finally use a G25 gel column for separation and purification, collect the labeled fluorescent material platinum porphyrin-labeled antibody, and use 0.01%-0.5% poly Ethylene glycol, 1%-5% bovine serum albumin, 5%-20% glycerin, and 0.01%-0.05% surfactant are diluted with 0.01M phosphate buffer solution, sealed in plastic bottles, and stored at 4°C.

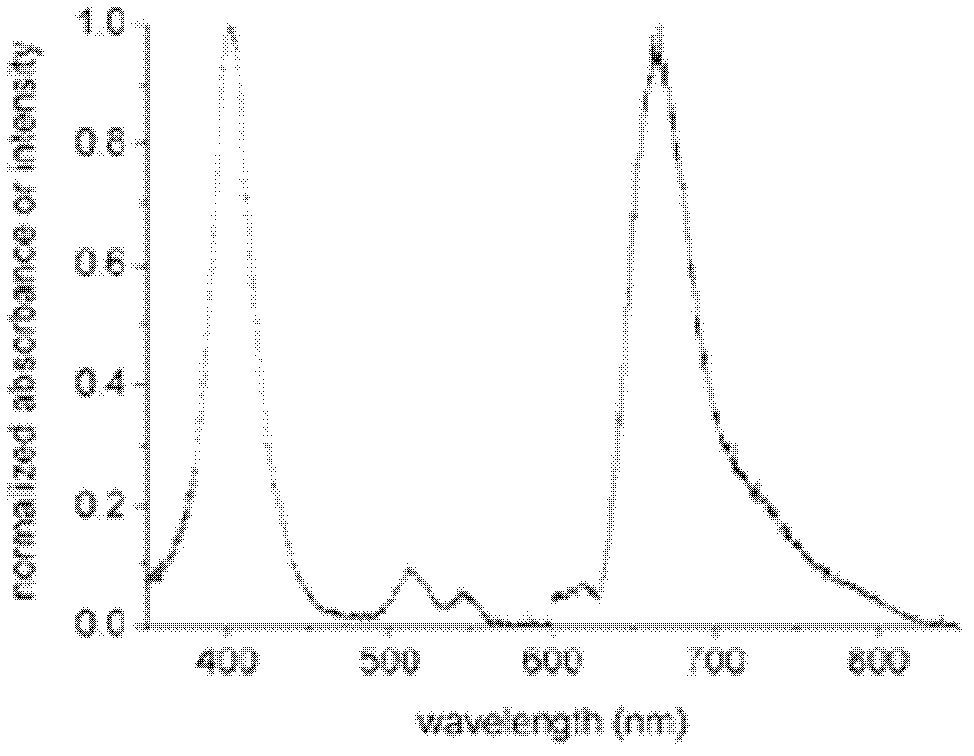

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com