Anode of nickel-metal hydride battery and preparation method of anode

A nickel-metal hydride battery and positive electrode technology, applied in battery electrodes, alkaline battery electrodes, circuits, etc., can solve the problems of low utilization rate of active materials and large internal resistance, and achieve improved performance and high current discharge capacity. The effect of expansion and improvement of utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

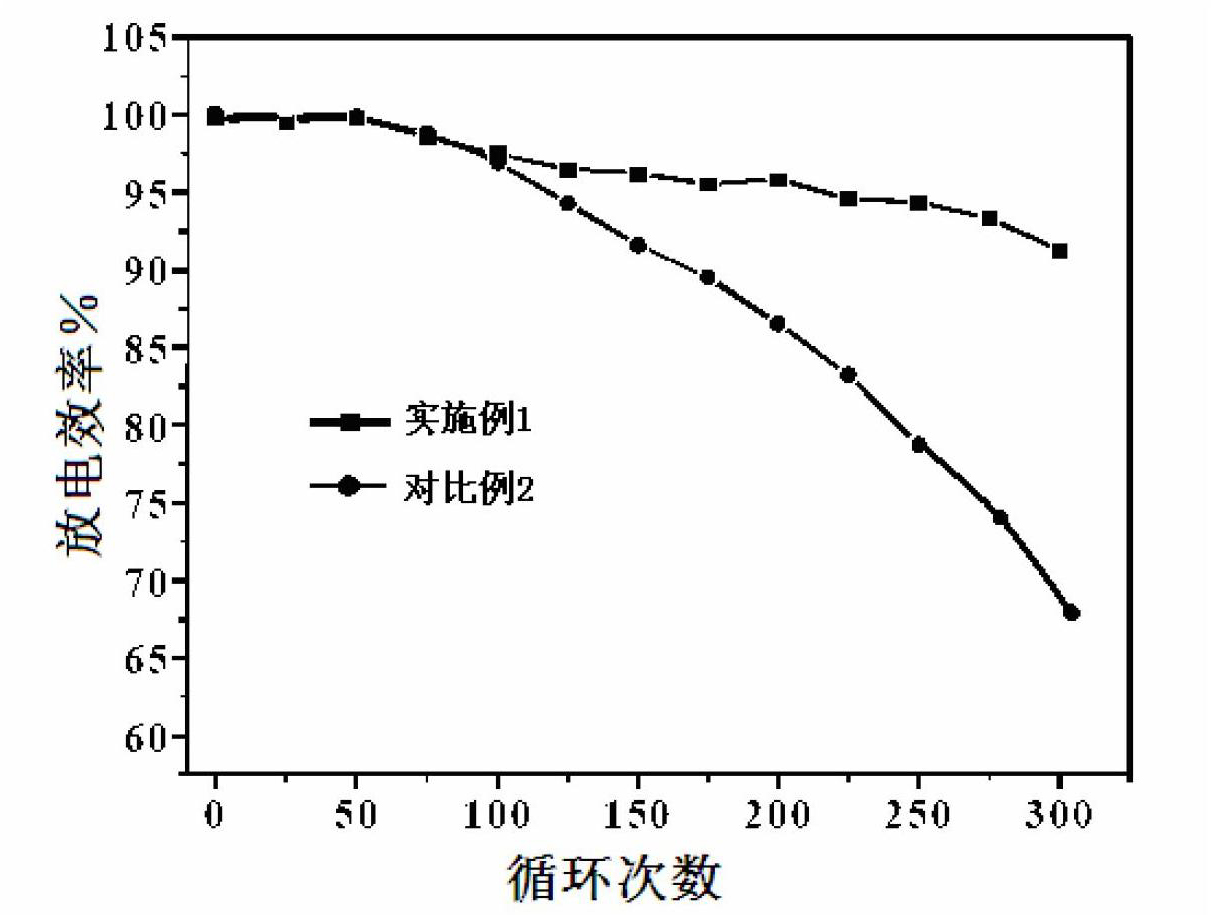

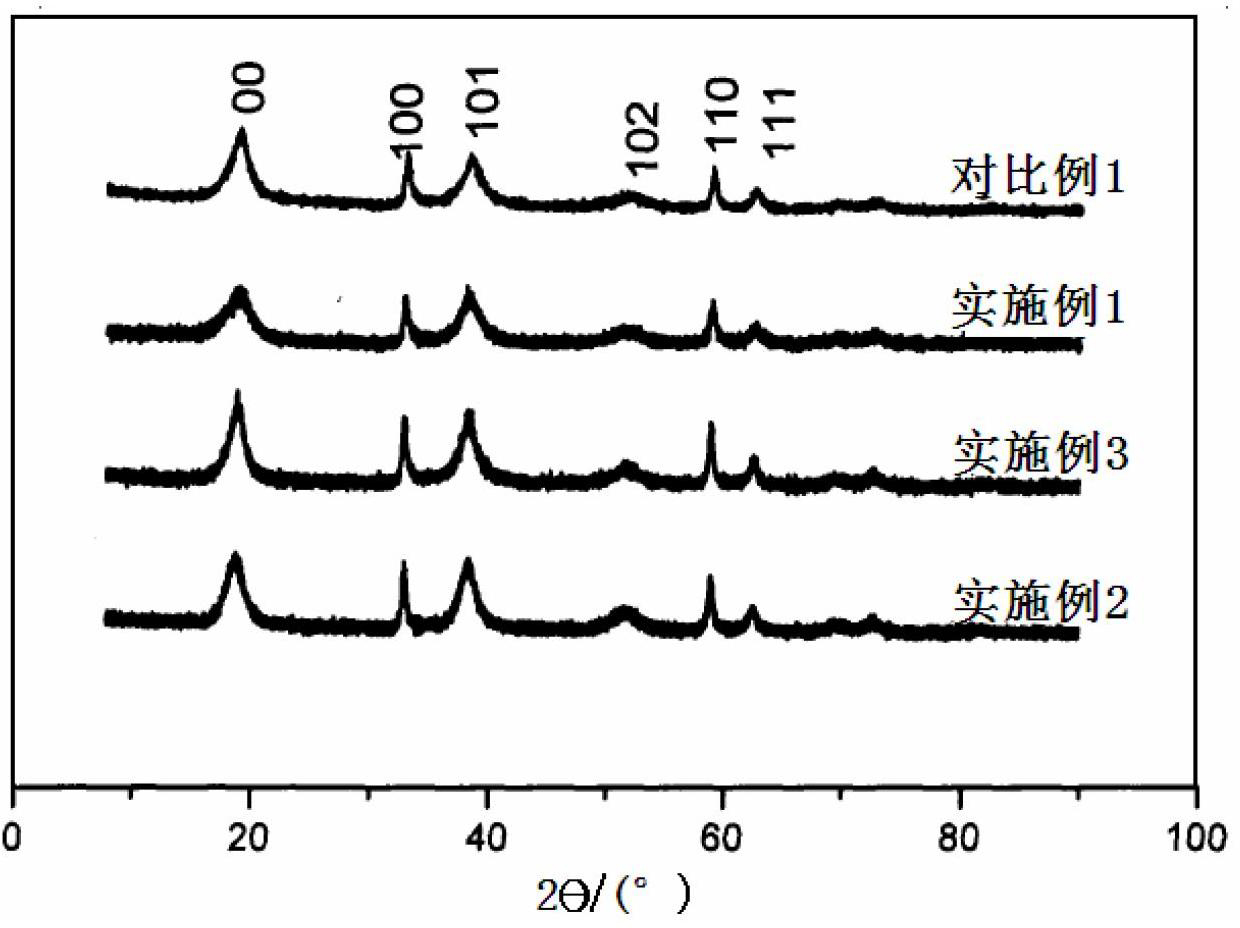

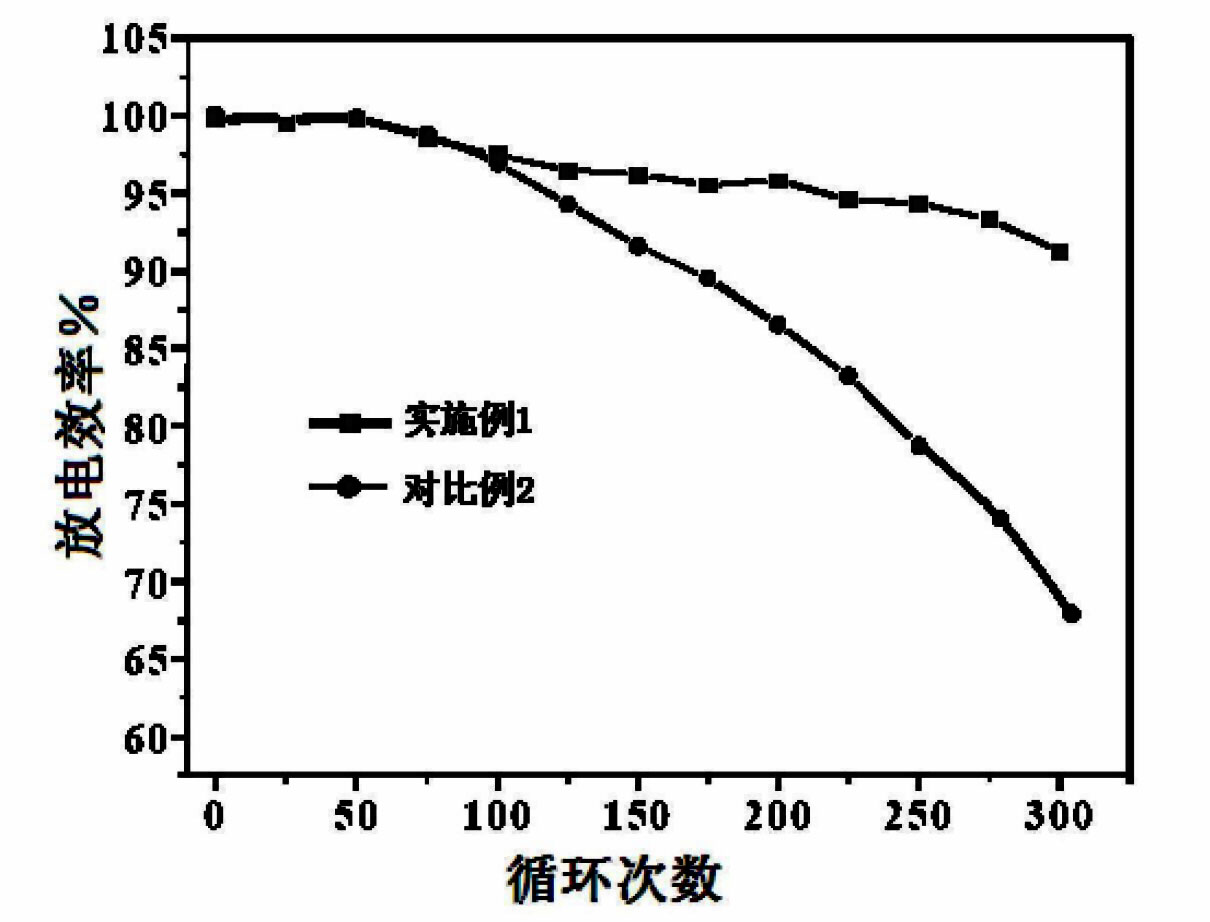

[0032] The positive electrode of the nickel-metal hydride battery of this embodiment includes a current collector and a positive electrode material filled and coated on the current collector. The positive electrode material includes a binder with a mass percentage content of 2% and 90% Mg-doped β-Ni. (OH) 2 and 8% nickel powder. The specific preparation method is as follows:

[0033] 1) Preparation of Mg-doped β-Ni(OH) by homogeneous complexation co-precipitation method 2 : Sodium hydroxide is added in the mixed solution of magnesium sulfate and nickel sulfate, react to generate crystallization; Wash after solid-liquid separation, dry, obtain the β-Ni(OH) doped with Mg 2 ; The mol ratio of the nickel salt, magnesium sulfate and sodium hydroxide added is 2:0.1:2;

[0034] 2), the Mg-doped β-Ni(OH) prepared in step 1) 2 After mixing evenly with 90% by mass percentage and 8% by mass of nickel powder, add 2% by mass of binder (HPMC and PTFE with a mass ratio of 1:1) and stir e...

Embodiment 2

[0037] The positive electrode of the nickel-metal hydride battery of this embodiment includes a current collector and a positive electrode material filled and coated on the current collector. (OH) 2 and 15% nickel powder. The specific preparation method is as follows:

[0038] 1) Preparation of Mg-doped β-Ni(OH) by homogeneous complexation co-precipitation method 2 : Sodium hydroxide is added in the mixed solution of magnesium sulfate and nickel nitrate, reacted to generate crystallization; Wash after solid-liquid separation, dry, obtain the β-Ni(OH) doped with Mg 2 ; The mol ratio of the nickel nitrate, magnesium sulfate and sodium hydroxide added is 2:0.3:3;

[0039] 2), the Mg-doped β-Ni(OH) prepared in step 1) 2 After mixing 80% by mass with 15% by mass of nickel powder, add 5% by mass of binder (HPMC and PTFE with a mass ratio of 1:1.5) and stir evenly to form a slurry, scrape coating into the collector;

[0040] 3) After drying at 110°C, press molding.

Embodiment 3

[0042]The positive electrode of the nickel-metal hydride battery of this embodiment includes a current collector and a positive electrode material filled and coated on the current collector. The positive electrode material includes a binder with a mass percent content of 3%, and 85% Mg-doped β-Ni. (OH) 2 and 12% nickel powder. The specific preparation method is as follows:

[0043] 1) Preparation of Mg-doped β-Ni(OH) by homogeneous complexation co-precipitation method 2 : Sodium hydroxide is added in the mixed solution of magnesium sulfate and nickel sulfate, react to generate crystallization; Wash after solid-liquid separation, dry, obtain the β-Ni(OH) doped with Mg 2 ; The mol ratio of the nickel sulfate, magnesium sulfate and sodium hydroxide that adds is 2:0.2:2.5;

[0044] 2), the Mg-doped β-Ni(OH) prepared in step 1) 2 After mixing evenly with 85% by mass percent and 12% by mass of nickel powder, add 3% by mass of binder (HPMC and PTFE with a mass ratio of 1:1.2) and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com