Resourceful treatment method for high-salinity wastewater

A technology of high-salt wastewater and treatment method, applied in the direction of oxidized water/sewage treatment, etc., can solve the problems of unbearable enterprises, high investment and operating costs, and achieve the effect of protecting the water environment, realizing resource utilization, and promoting sustainable development.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

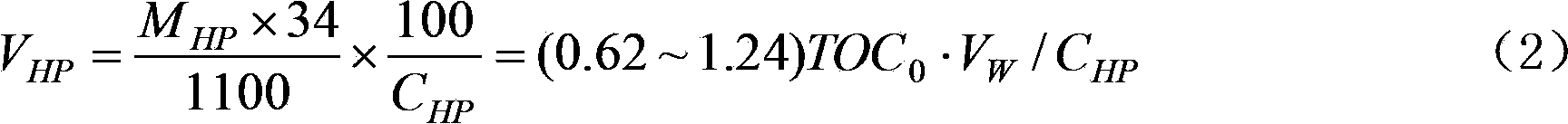

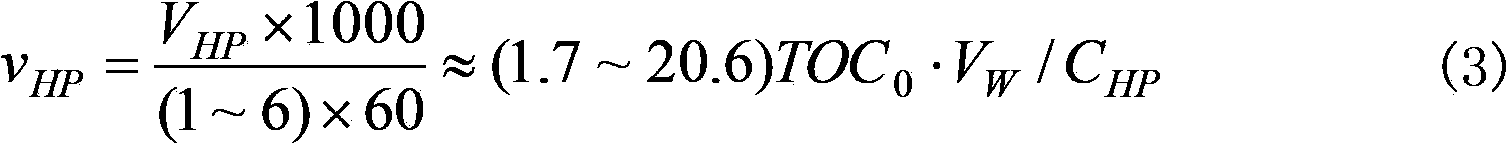

[0058] Step 1: Use hydrochloric acid to adjust the pH value of epichlorohydrin wastewater (TOC=1620mg / L, NaCl=21.5%) to 3.0, then add 800mL of the pH-adjusted water sample to a 1000mL three-necked round-bottomed flask, and then add the three-necked The flask was placed in a constant temperature water bath at 90°C. A stirring bar was installed in one of the middle ports of the three-necked flask, and a pH electrode was inserted into the other two ports, and the other was used as a drug dosing port. Turn on the mechanical stirring and preheat the water sample.

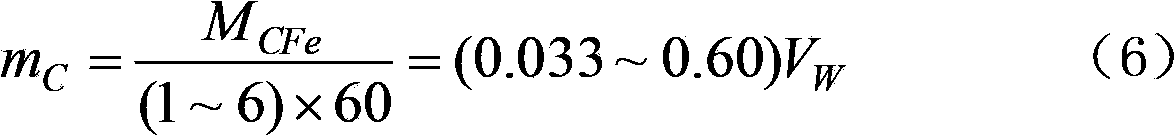

[0059] Step 2: Weigh ferrous chloride (FeCl 2 4H 2 O) 4.3g (about 21.6mmol), then dissolve it in 10mL of water as a catalyst; use a measuring cylinder to take 45mL of 30% hydrogen peroxide (about 0.44mol) as an oxidizing agent.

[0060] Step 3: When the temperature of the water sample in the three-necked flask is basically the same as the temperature of the water bath, add 0.5mL of catalyst dropwise from the dosing por...

Embodiment 2

[0064] Step 1: Except that the temperature of the water bath is 80° C., the others are all the same as in Example 1.

[0065] Step 2-Step 4: Same as Example 1.

[0066] The TOC was measured and the result was 128mg / L, which met the requirement of TOC<200mg / L for the brine entering the diaphragm electrolyzer.

Embodiment 3

[0068] Step 1: Same as Example 2.

[0069] Step 2: Weigh ferrous chloride (FeCl 2 4H 2 O) 4.3g (about 21.6mmol) and copper chloride (CuCl 2 2H 2 O) 0.1g (about 0.06mmol), and mix the two together, then dissolve the mixture of the two in 10mL of water as a catalyst; use a measuring cylinder to take 45mL of 30% hydrogen peroxide (about 0.44mol) as an oxidizing agent .

[0070] Step 3 and step 4 are the same as in Example 1.

[0071] The TOC measurement result is 90mg / L, which meets the requirement of TOC<200mg / L for the brine entering the diaphragm electrolyzer.

[0072] Comparing Examples 2 and 3, it can be seen that adding a small amount of copper chloride in ferrous chloride can improve the effect of catalytic wet peroxide oxidation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com