High-saturation-flux-density MnZn ferrite material and preparation method thereof

A technology of ferrite material and magnetic flux density, which is applied in the field of high saturation magnetic flux density MnZn ferrite material and its preparation, can solve the problems of high price and increased production cost of ferrite materials, and achieve energy saving, High saturation magnetic flux density and miniaturization effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

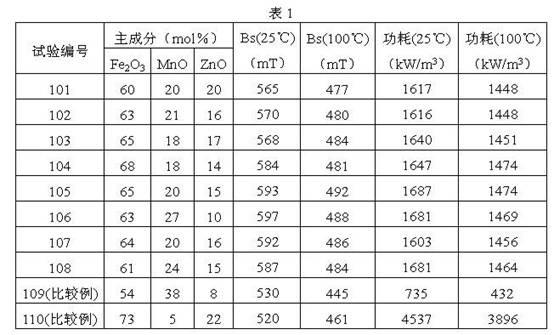

Embodiment 1

[0029] Weigh Fe with the main component content shown in Table 1 2 o 3 , MnO, and ZnO raw materials were wet-mixed, and then pre-fired at 900°C for 2 hours. Add 100ppm of SiO to the pre-fired mixture based on the weight of the main component 2 , 1000ppm of CaCO 3 , 200ppm ZrO 2 , 200ppm Nb 2 o 5 and 300ppm V 2 o 5 , wet sanding to obtain a ferrite slurry. Add 1wt% PVA binder calculated by ferrite powder weight to the slurry for spray granulation. at 1 ton / cm 2 Under high pressure, the granulated powder is molded into a standard ring ferrite core for testing. The molded body is sintered at 1330°C for 5 hours under the condition of controlled oxygen partial pressure, wherein the oxygen partial pressure concentration is 0.001% in the heating stage from 900°C to 1330°C, and then cooled to room temperature under the protection of nitrogen. The final composition of the ferrite core was detected to be consistent with the design composition by an X-ray fluorescence analyzer...

Embodiment 2

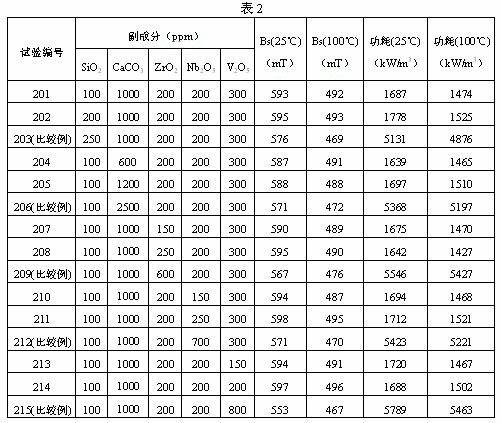

[0034] The preparation process of the magnetic core is the same as that of Example 1. Only Fe in the main ingredient formula 2 o 3 , MnO, ZnO content fixed at 65mol% Fe 2 o 3 , 20 mol% of MnO and 15 mol% of ZnO. The addition amount of auxiliary component is as shown in table 2.

[0035]

[0036] It can be seen from Table 2 that when the content of the secondary components is within the scope of the present invention, the volume power consumption of the magnetic core is low and the saturation magnetic flux density is high. When the content of the subcomponent deviates from the range of the present invention, the saturation magnetic flux density tends to decrease or the power consumption tends to increase.

Embodiment 3

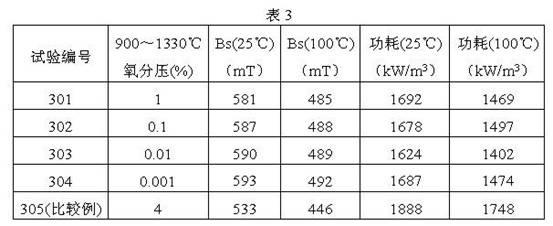

[0038] The composition of the magnetic core is the same as that of test number 105#, and the preparation process is the same as that of Example 1. Only the oxygen partial pressure concentration in the temperature rising section from 900°C to 1330°C is shown in Table 3.

[0039]

[0040] It can be seen from Table 3 that when the oxygen partial pressure concentration is higher than 1%, the saturation magnetic flux density of the magnetic core is greatly reduced.

PUM

| Property | Measurement | Unit |

|---|---|---|

| saturation flux density | aaaaa | aaaaa |

| saturation flux density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com