Process for preparing polysucrose

A process method, polysucrose technology, which is applied in the field of compound preparation, can solve the problems of insufficient yield and purity of polysucrose, and achieve the effects of short reaction process, mild reaction conditions, and improved yield and purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

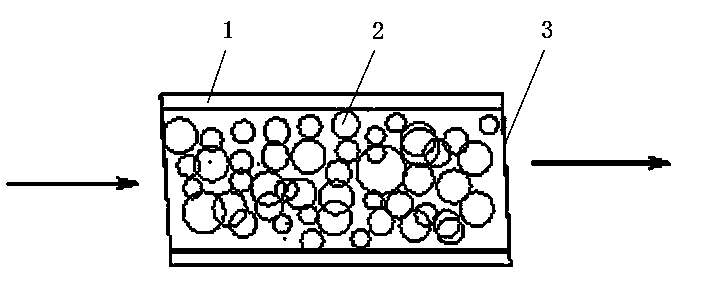

Image

Examples

Embodiment 1

[0014] 80g sucrose, 24ml (ie 24g) distilled water, 40g epibromopropane were loaded into a device with a ceramic film thickness of 2cm loaded with D201 resin, and reacted at 25°C for 2 hours, and the pH value of the reaction was 12, so that the mixture was Polymerization was carried out on a strong basic anion exchange resin, the temperature was raised to 60° C., and the reaction was continued for 2 hours, and then the reaction solution was eluted with distilled water, and the product low-cross-linked polysucrose was adsorbed on the resin. The product was purified with acetone, and the low-cross-linked polysucrose was eluted and fractionated with absolute ethanol, and the selected low-cross-linked polysucrose had a weight-average molecular weight of 300,000.

[0015] In a 250ml three-necked flask equipped with a stirring device, add 5g of low-cross-linked polysucrose, 20ml of distilled water, and 3ml of epibromopropane, and fully stir to mix them uniformly. 3 ml of Span 85 was ...

Embodiment 2

[0017] In a 250ml three-necked flask with a stirring device, add 5g of the low-crosslinked polysucrose prepared in Example 1, 20ml of distilled water, and 4ml of epibromopropane, and fully stir to mix them uniformly. 3 ml of Tween 85 was added to 150 ml of chlorobenzene to the mixture, and the pH was adjusted to 13 with aqueous sodium hydroxide solution. Then, the water bath was reacted at 70°C for 1.5 hours, and a large number of microspheres appeared. After curing at 90°C for 9.5 hours, the product was filtered and washed with absolute ethanol and distilled water for several times to obtain transparent spherical particles, which were dried, and the yield was 95.9%. %.

Embodiment 3

[0019] In a 250ml three-necked flask with a stirring device, add 5g of the low-crosslinked polysucrose prepared in Example 1, 20ml of distilled water, and 4ml of epibromopropane, and fully stir to mix them uniformly. 4.2 ml of Span 85 was added to 150 ml of liquid paraffin and added to the mixture, and the pH was adjusted to 12 with aqueous sodium hydroxide solution. Then the water bath was reacted at 75°C for 1.5 hours, and a large number of microspheres appeared. After curing at 95°C for 10 hours, the product was filtered and washed with absolute ethanol and distilled water for several times to obtain transparent spherical particles, which were dried, and the yield was 94.6%. %.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com