Method for preparing catalase by using bovine livers

A technology of catalase and bovine liver, which is applied in the direction of biochemical equipment and methods, enzymes, enzymes, etc., can solve the problems of no industrial production, and achieve the effects of high yield, short extraction time and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

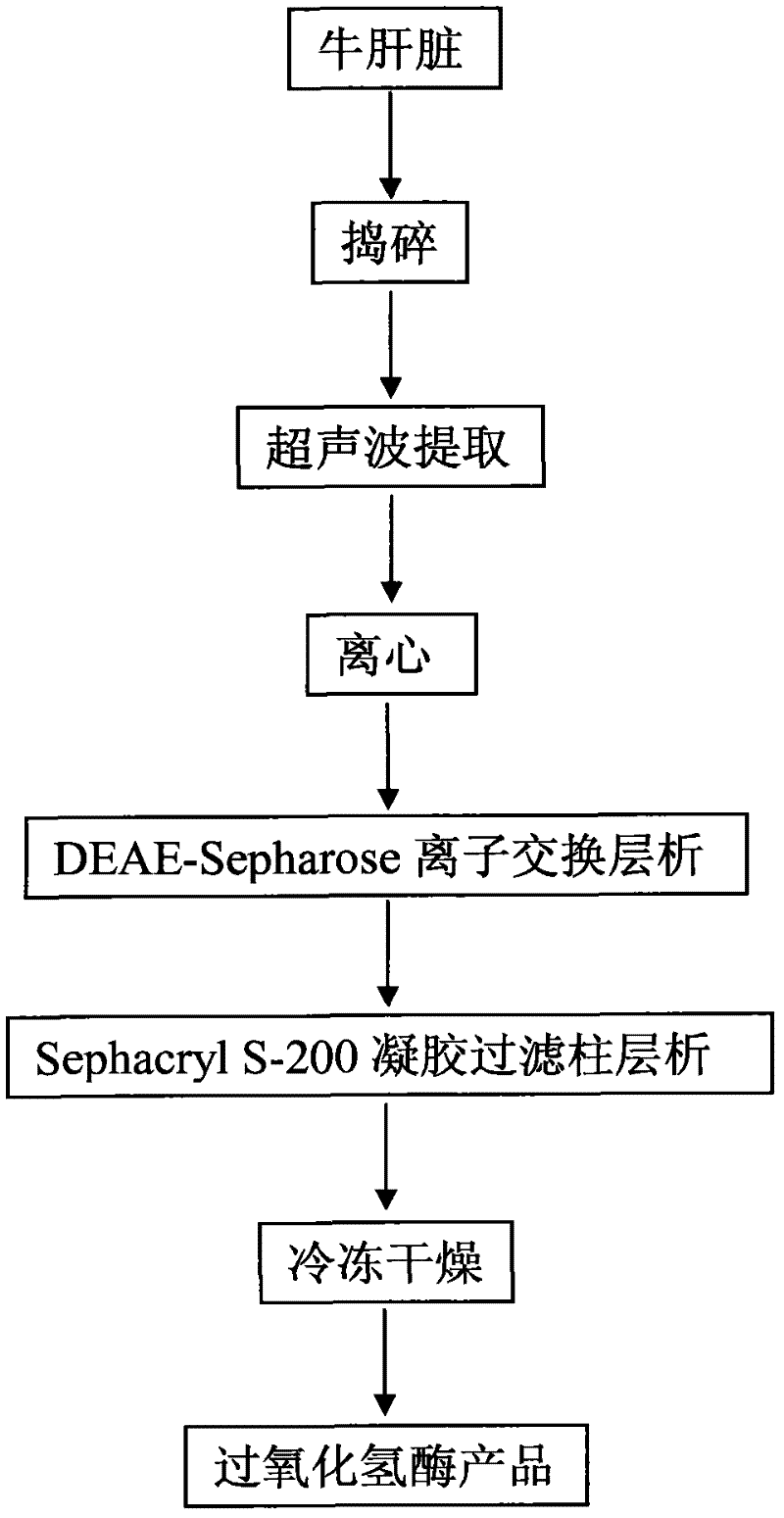

Image

Examples

example 1

[0024] Weigh 5 kg of fresh beef liver, wash it with tap water, chop it up, mash it with a tissue mashing homogenizer, and make a homogenate for subsequent use. Take the bovine liver homogenate, use phosphate buffer (pH 7.2) as the extraction agent, the ratio of bovine liver and extraction agent is 1:3, the extraction temperature is 30°C, and the ultrasonic intensity is 30W. Hydrogenase extract. The above extract was passed through a DEAE-Sepharose ion-exchange chromatography column, equilibrated with phosphate buffer (0.05mol / L, pH 7.2) for 4 times the column volume, and loaded; pH 7.2 phosphate buffer) for gradient elution at a flow rate of 30 mL / h. The above-mentioned enzyme solution was subjected to gel filtration chromatography, using a Sephacryl S-200 gel column, washed with phosphate buffer (0.05mol / L, pH 7.2) after packing, loading, and washed with phosphate buffer (0.05mol / L , pH 7.2) for elution at a flow rate of 18 mL / h. Then, the enzyme solution was dialyzed at 4...

example 2

[0026] Weigh 10 kg of fresh beef liver, wash it with tap water, chop it up, mash it with a tissue mashing homogenizer, and make a homogenate for subsequent use. Take the bovine liver homogenate, use phosphate buffer (pH 7.2) as the extraction agent, the ratio of bovine liver and extraction agent is 1:4, the extraction temperature is 30°C, and the ultrasonic intensity is 40W and treated for 15 minutes to obtain peroxidized Hydrogenase extract. The above extract was passed through a DEAE-Sepharose ion-exchange chromatography column, equilibrated with phosphate buffer (0.05mol / L, pH 7.2) for 5 times the column volume, and loaded; with 0-1mol / L NaCl solution (containing 0.05mol / L, pH phosphate buffer in 7.2) for gradient elution at a flow rate of 30 mL / h. The above-mentioned enzyme solution was subjected to gel filtration chromatography, and a Sephacryl S-200 gel column was used. After loading the column, it was washed with phosphate buffer (0.05 mol / L, pH 7.2), and the sample wa...

example 3

[0028] Weigh 50 kg of fresh beef liver, wash it with tap water, chop it up, mash it with a tissue mashing homogenizer, and make a homogenate for subsequent use. Take the bovine liver homogenate, use phosphate buffer (pH 7.2) as the extraction agent, the ratio of bovine liver and extraction agent is 1:5, the extraction temperature is 30°C, and the ultrasonic intensity is 45W and treated for 20min to obtain peroxidized Hydrogenase extract. The above extract was passed through a DEAE-Sepharose ion-exchange chromatography column, equilibrated with phosphate buffer (0.05mol / L, pH 7.2) for 5 times the column volume, and loaded; with 0-1mol / L NaCl solution (containing 0.05mol / L, pH phosphate buffer in 7.2) for gradient elution at a flow rate of 35 mL / h. The above-mentioned enzyme solution was subjected to gel filtration chromatography, and a Sephacryl S-200 gel column was used. After loading the column, it was washed with phosphate buffer (0.05 mol / L, pH 7.2), and the sample was loa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com