Iron ore reducing agent, iron ore mixture and method for reducing iron ore

A technology of iron ore and reducing agent, applied in the field of iron ore reducing agent, can solve the problems that specular iron ore cannot be used, resources have not been developed and utilized, unfavorable sintering, pelletizing, agglomeration, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-5

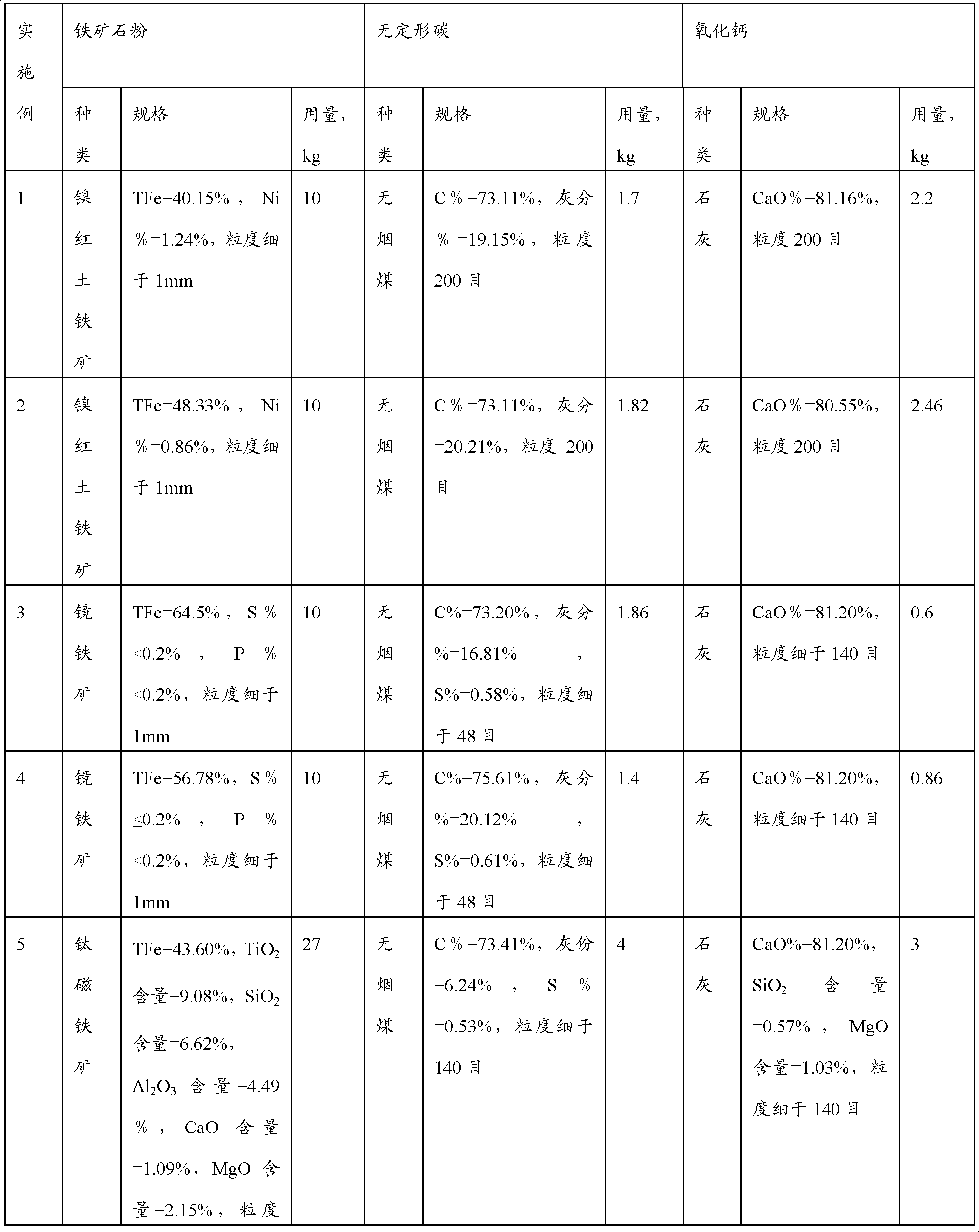

[0128] The preparation of embodiment 1-5 iron ore mixture 1-5

[0129] Under normal temperature and pressure, iron ore powder, anthracite and lime were uniformly mixed as shown in Table 1 in conventional mixing equipment to obtain iron ore mixture 1-5.

[0130] Table 1 Iron Ore Mixture 1-5

[0131]

[0132]

[0133] Note: TFe: total iron content, based on ore weight

[0134] C%: fixed carbon content, based on the weight of ore or anthracite

[0135] Ash %: Ash content, based on the weight of anthracite coal

[0136] The remaining weight percentages are based on the weight of the corresponding material (iron ore, anthracite, lime)

Embodiment 6-10

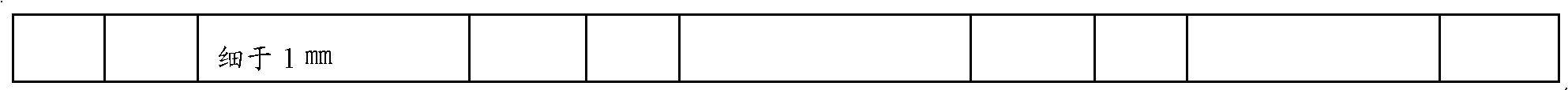

[0137] Embodiment 6-10 reduction reaction and obtain iron powder

[0138] Put the iron ore mixture 1-5 obtained above into a silicon carbide reduction tank, put the tank into a tunnel kiln, and use liquefied gas as fuel under the conditions shown in Table 2 below to preheat and For the reduction reaction, the air volume is controlled so that the combustion flame in the tunnel kiln is orange, thereby ensuring that the reaction step is carried out under a reducing atmosphere. After a predetermined reaction time, the product is cooled and crushed to a particle size of less than 0.3mm, and then iron powder is magnetically separated. Table 2 also gives the total iron content, yield and other impurity information of the obtained iron powder. During the preheating process, all examples were heated from ambient temperature to 1100° C. within the time shown in Table 2. The whole preheating and reduction reaction process is carried out under normal pressure.

[0139] Table 2

[0140...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com