Determination method of arsenic content in hot melt glue

A measurement method, hot-melt adhesive technology, applied in the field of physical and chemical inspection, can solve the problems of cumbersome operating procedures, low sensitivity, and great physical harm to operators, and achieve accurate detection results, accurate detection, and less interference in the measurement process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0057] The present invention will be further described below in conjunction with example, but not limit the present invention:

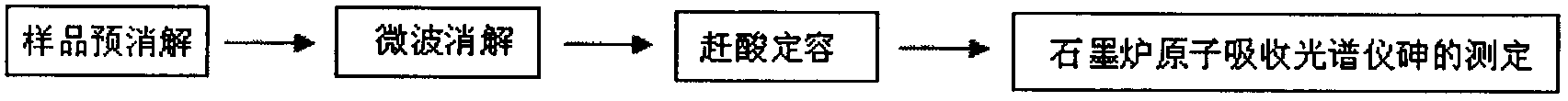

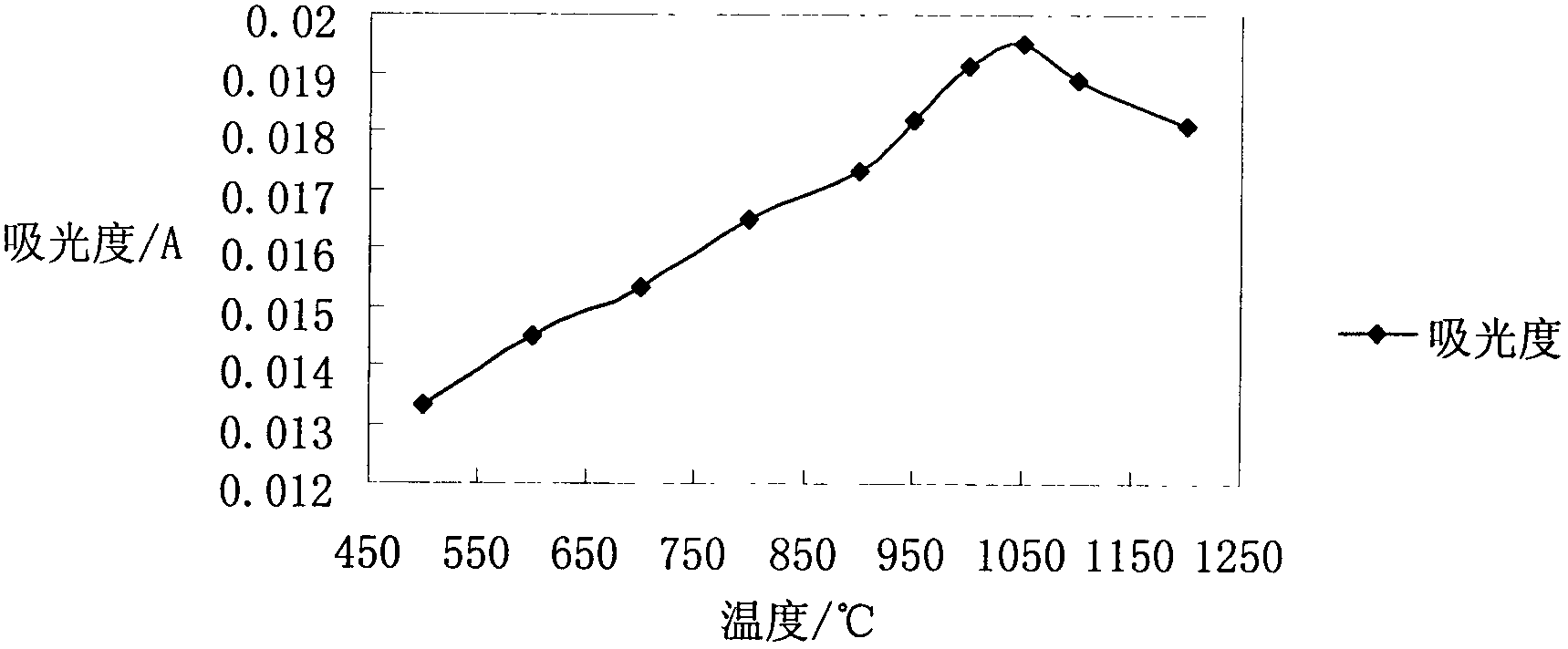

[0058] A method for determining arsenic in hot-melt adhesives. The testing process is to digest a weighed hot-melt adhesive sample with mixed acid, dissolve it with 0.2% nitric acid, and set the volume to a certain volume. Take an appropriate amount of sample liquid and collective improver in the graphite furnace atomizer, after drying, ashing, and atomization, under the selected parameters, the arsenic absorption wavelength of the element to be measured is the resonance line of 193.7nm, and its absorbance is the same as that of arsenic The content is directly proportional, and it is quantitative compared with the standard series.

example 1

[0060]1. Instruments and reagents: PTFE volumetric flask, 50mL. Analytical balance, the sensitivity is 0.0001g. Teflon beaker, 100mL. Airtight microwave digestion instrument (with microwave digestion tank). Temperature controlled electric heater. Graphite Furnace Atomic Absorption Spectrometer. Water, ultrapure water or double distilled water of equivalent purity. Nitric acid, 68%, nitric acid 0.2%, hydrogen peroxide, 30%, hydrochloric acid, 37%, hydrofluoric acid, 40%, ammonium dihydrogen phosphate solution, 1.0g / L palladium nitrate solution, 10 / L, arsenic standard solution

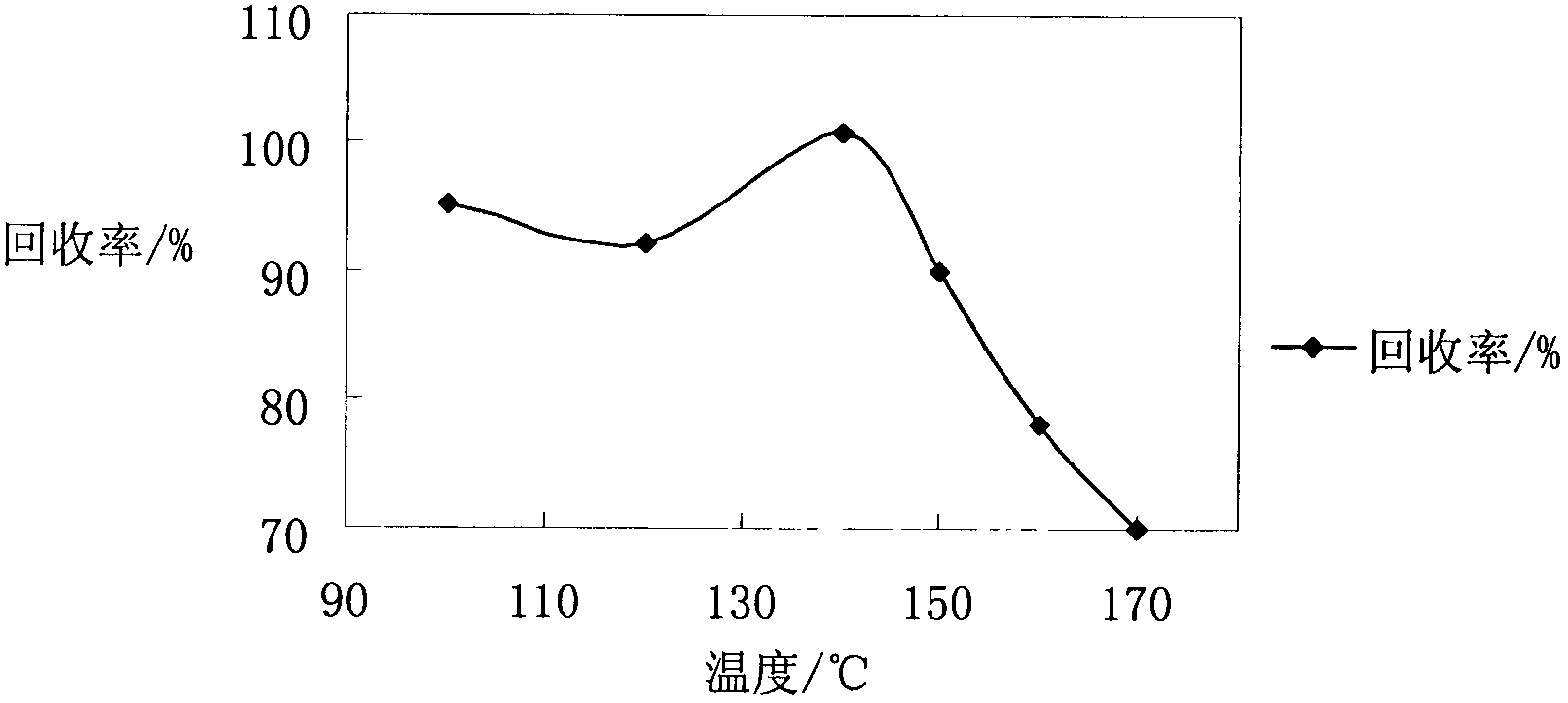

[0061] 2. Sample treatment: accurately and accurately weigh 0.2 g of hot melt adhesive sample A, place it in a microwave digestion tank, and add a certain volume of nitric acid (68% concentration) and hydrogen peroxide (30% concentration) to the microwave digestion tank. ), hydrochloric acid (concentration is 37%), hydrofluoric acid (concentration is 40%), pack into microwave digestion instrument af...

example 2

[0064] As described in Example 1, the hot melt adhesive sample of brand B is selected, and the arsenic in the sample is measured to be 0.06mg / kg

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com