Novel high-power permanent magnet brushless motor

A permanent magnet brushless motor, high-power technology, applied in the direction of electric components, electrical components, electromechanical devices, etc., can solve the problems of electrochemical corrosion of balls and raceways, broken and falling off of magnetic steel, and large number of lead wires, etc. The effect of high overall strength, reduced material loss and simple winding process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The present invention will be described in further detail below in combination with specific embodiments.

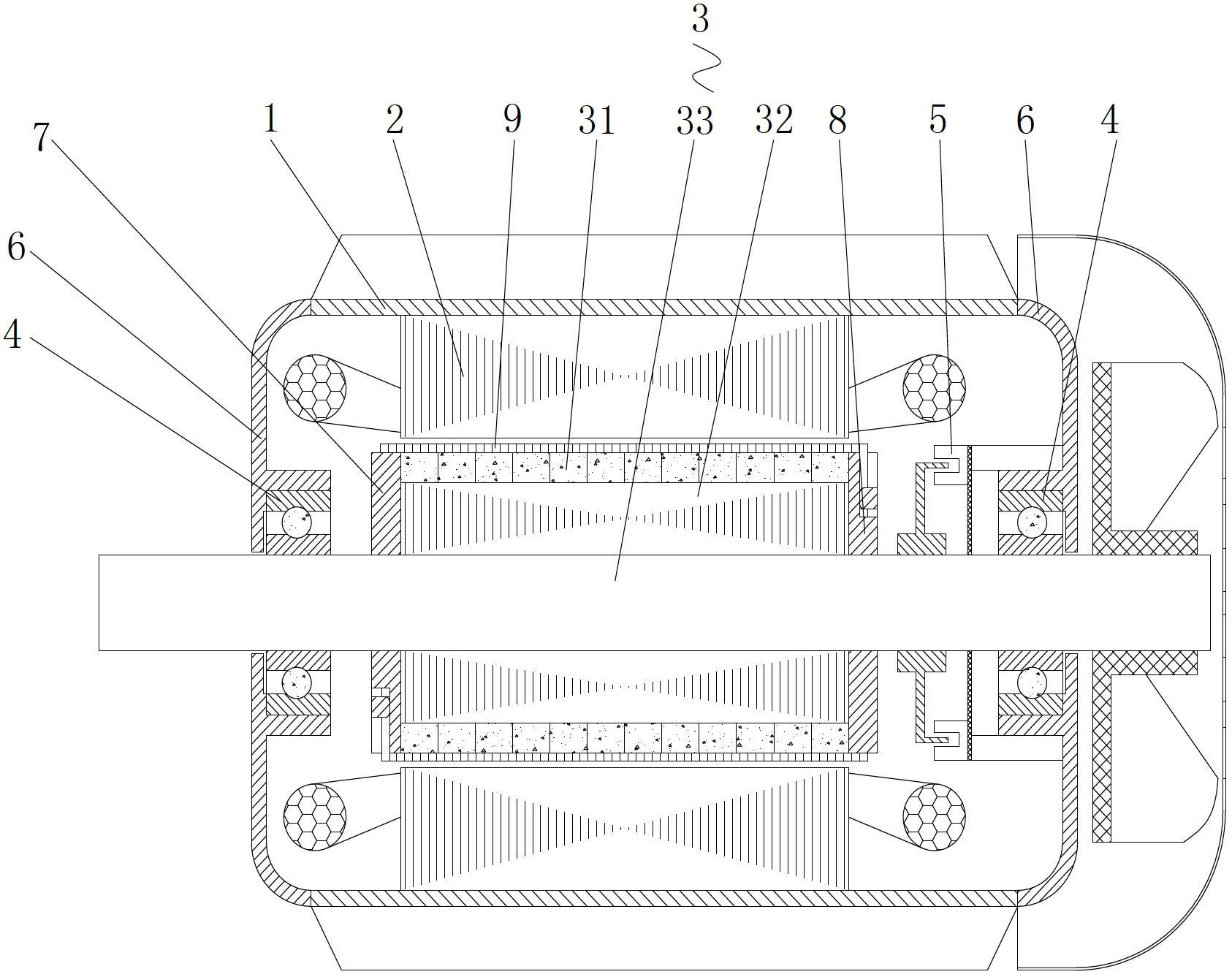

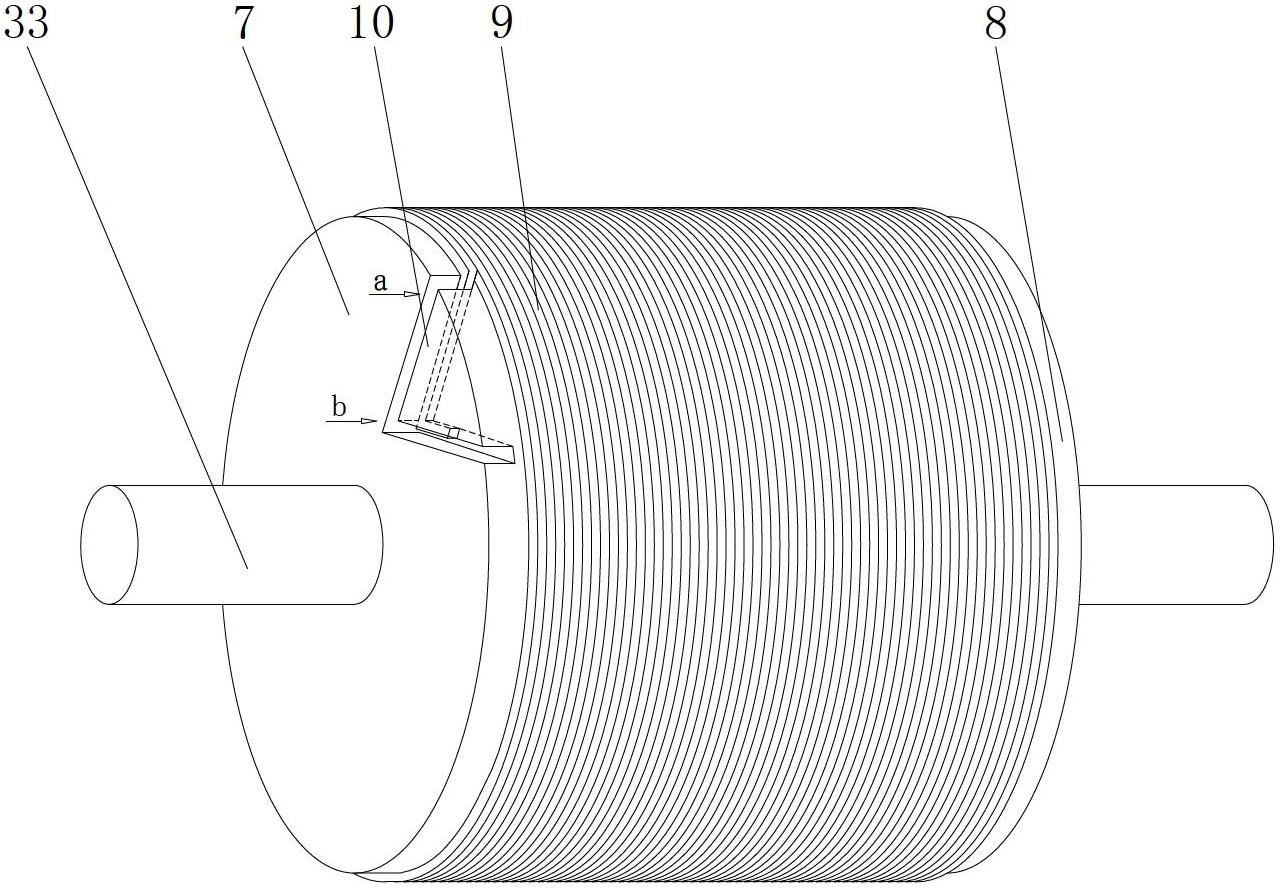

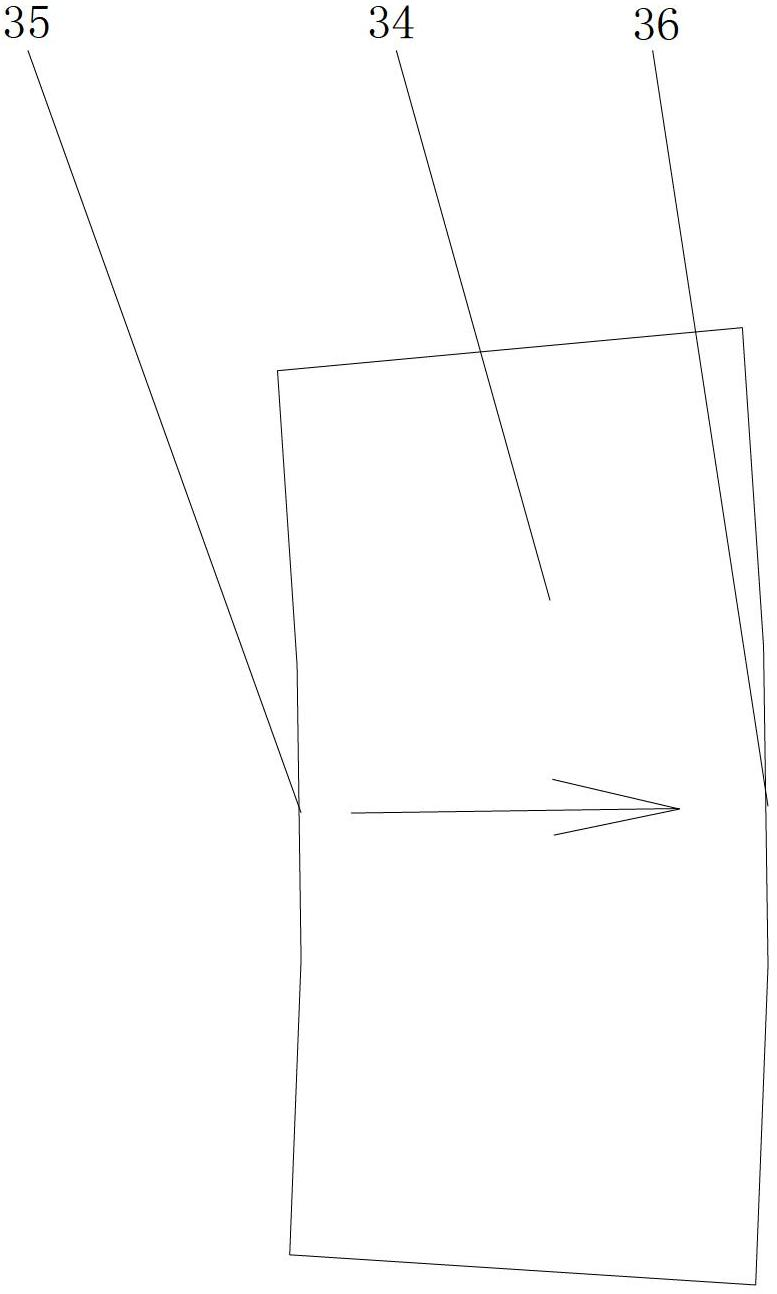

[0047] Such as Figure 1-7 As shown in one of the above, a new high-power permanent magnet brushless motor of the present invention includes a base 1, a stator 2, a rotor 3, a bearing 4 and a position sensor device 5, and the two ends of the base 1 are respectively provided with front and rear ends The cover 6; the stator 2, the rotor 3, the bearing 4 and the position sensor device 5 are respectively arranged in the frame 1, and the front and rear ends of the rotor 3 are respectively provided with a front end plate 7 and a rear end plate 8, and the rotor 3 also includes a rotor magnetic steel 31. The rotor core 32 and the rotating shaft 33. The rotor core 32 is sleeved outside the rotating shaft 33, and the rotor magnetic steel 31 is sleeved outside the rotating shaft iron core 32; the rotor magnetic steel 31 is composed of several pieces of magnetic steel with di...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com