Resin catalyst applied to preparation of phenol through decomposition of cumene hydroperoxide (CHP) and preparation method for resin catalyst

A cumene hydrogen peroxide, catalyst technology, applied in the direction of organic compound/hydride/coordination complex catalyst, physical/chemical process catalyst, chemical instrument and method, etc., can solve the problem of weak oxidation resistance and short service life and other problems, to achieve the effect of short reaction time, long service life and improved oxidation resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

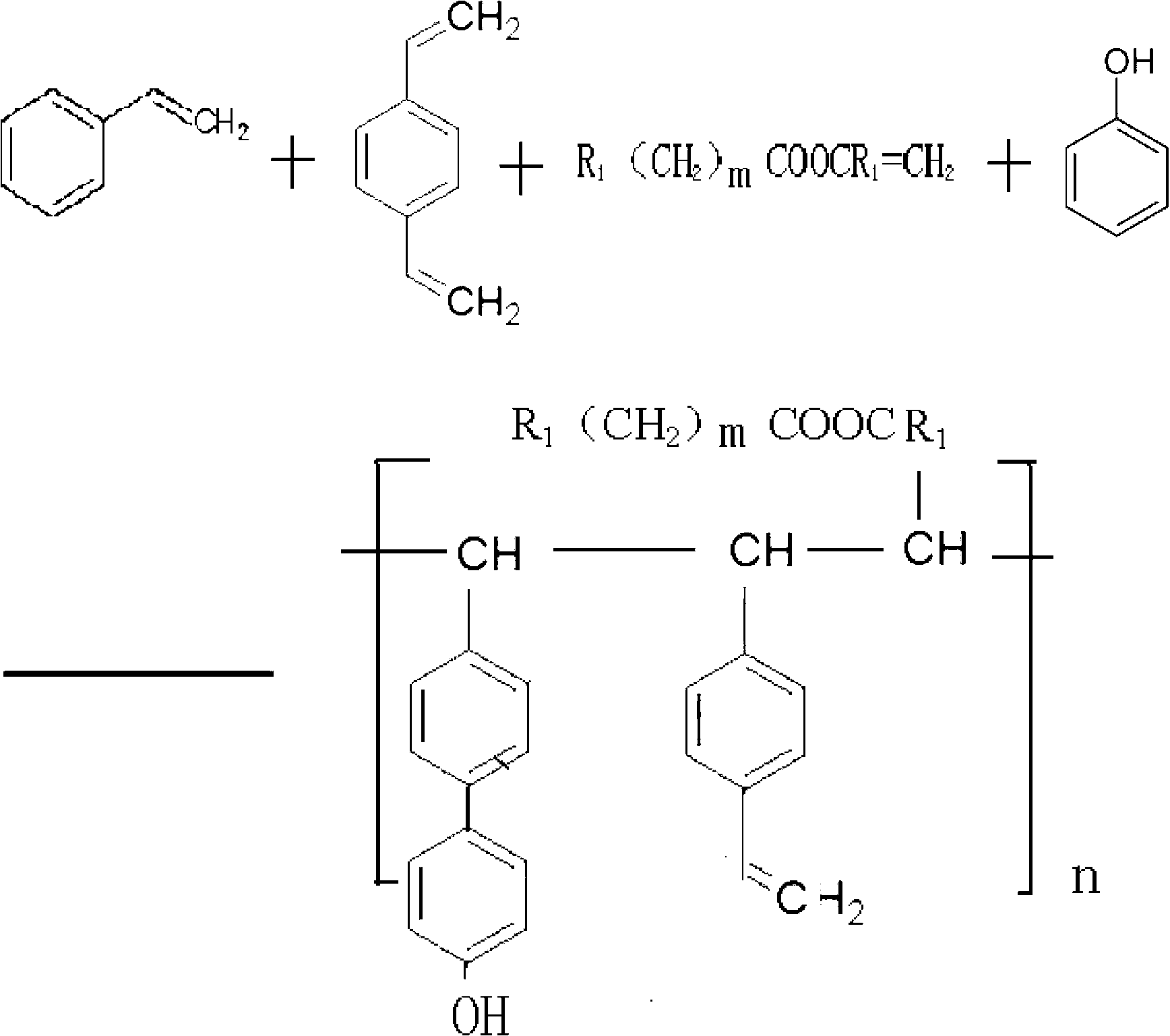

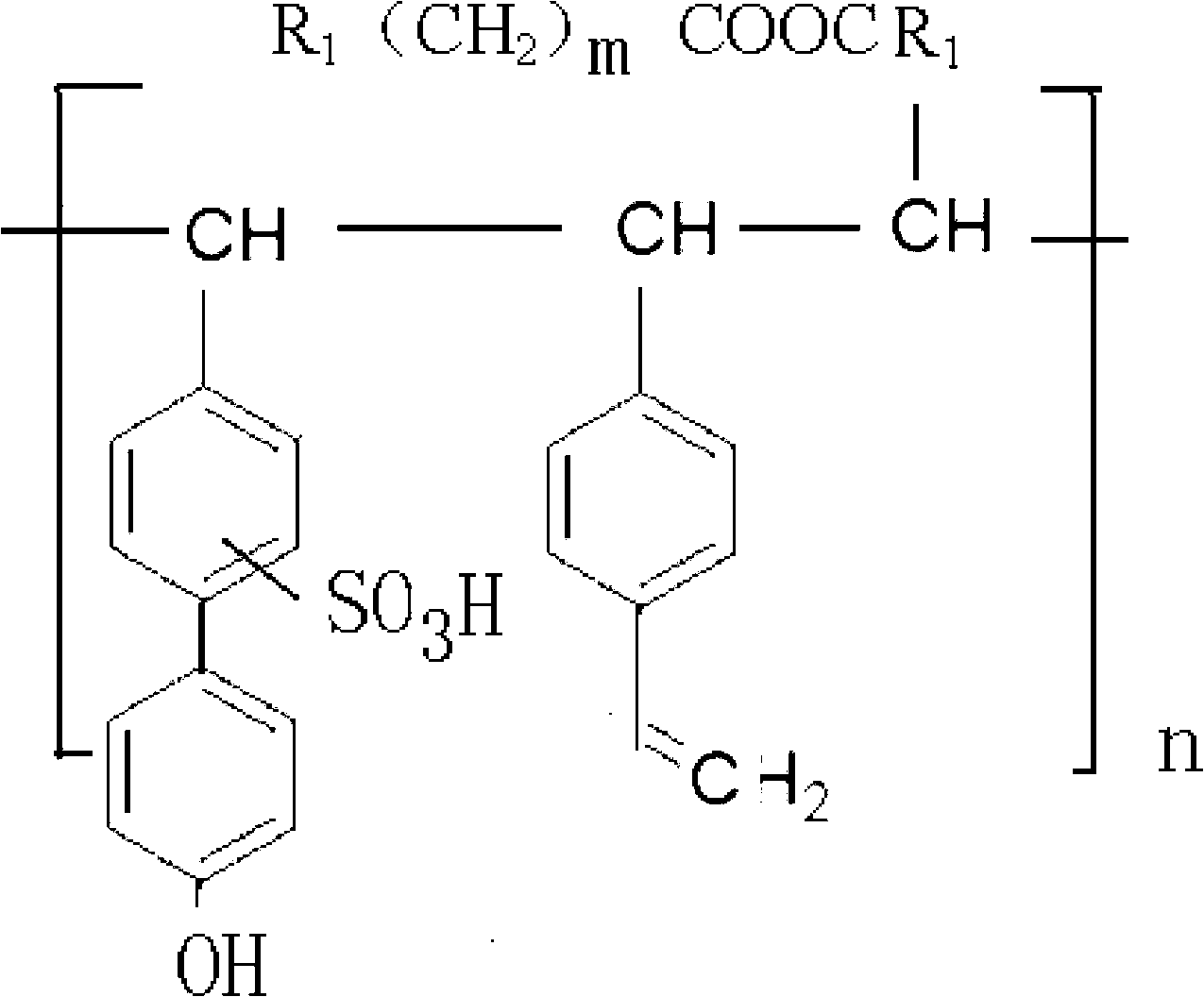

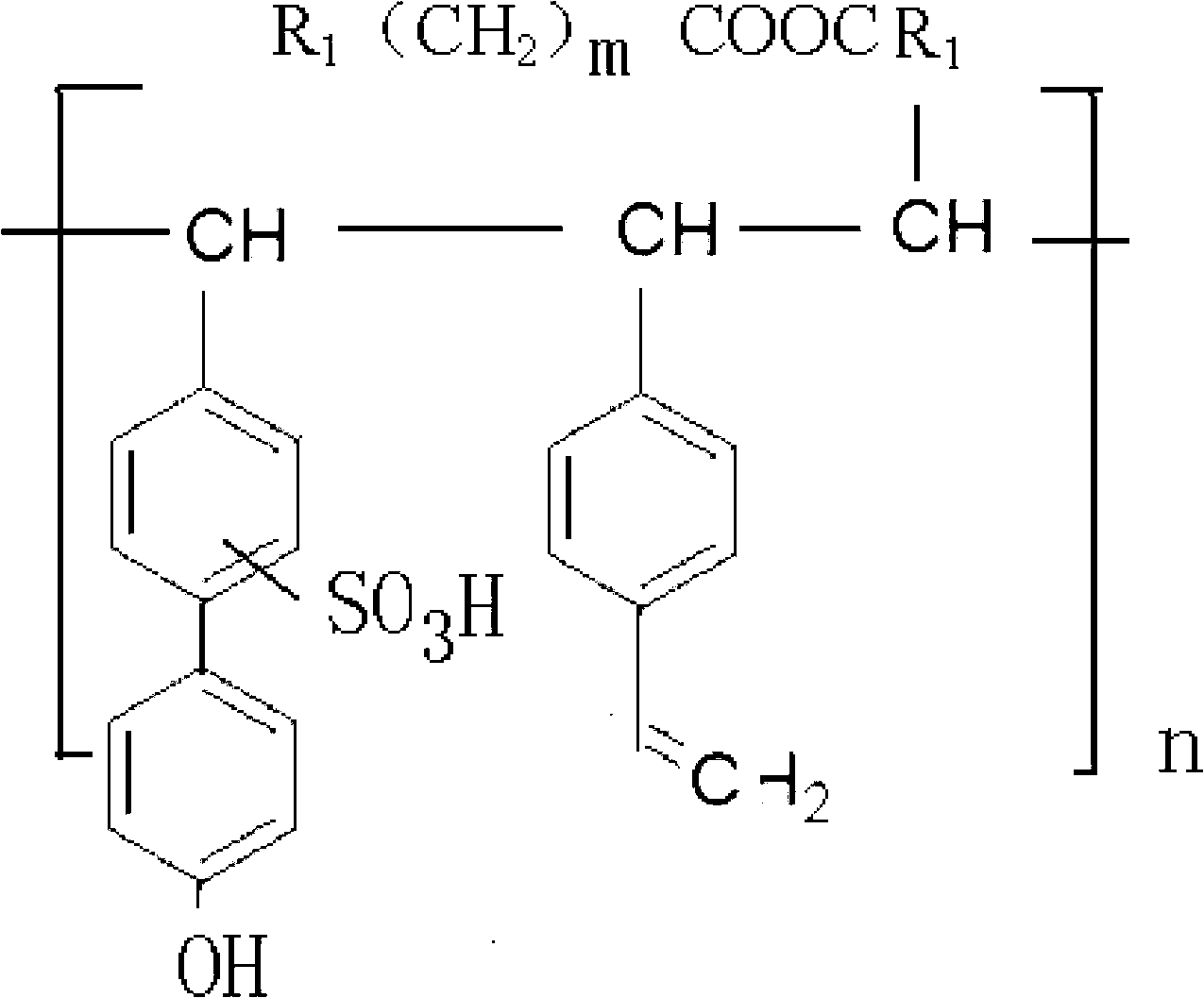

[0020] 1). Polymerization reaction

[0021] The well-known macroporous styrene-based ion-exchange resin polymerization production process is selected in the industry, and the cross-linking degree is controlled to 15%, and the porosity is 30%. In addition, hexafluorobutyl acrylate, which accounts for 0.1% of the monomer mass percentage, and 0.1% The phenol participates in the polymerization, and then the finished product is obtained through sulfonation and other processes. Designated as KRB-1

Embodiment 2

[0023] Polymerization reaction crosslinking degree 30%, others are the same as embodiment 1. The resulting product number is KRB-2.

Embodiment 3

[0025] Polymerization reaction crosslinking degree 22.5%, others are the same as embodiment 1. The resulting product number was KRB-3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com