Environment-friendly high-cost-performance long-life type lander castable and manufacturing method thereof

A cost-effective, long-life technology, applied in the field of castables for iron troughs, can solve problems such as wear of iron troughs, personal injury, environmental pollution, etc., achieve super wear-resistant service life, shorten baking time, and eliminate baking The effect of baked damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Example 1: The weight composition of raw materials is: 25 parts of 12-3mm recycled corundum particles, 20 parts of 3-1mm corundum particles, 25 parts of silicon carbide particles and micropowder mixture, 2 parts of 1-0mm resin particles, 10 parts of activated alumina micropowder , 3 parts of Guangxi mud, 2 parts of 0.8 μm silica powder, 1 part of 320 mesh metal silicon powder, 2 parts of cement, 0.1 part of β-naphthalenesulfonate sodium formaldehyde condensate, azodicarbonamide and metal aluminum powder weight ratio 1: 0.1 part of the mixture of 1 and 5 parts of water. After mixing the above-mentioned raw materials except raw material water in proportion, add water and mix evenly at the pouring ditch site, add it to the mold cavity and vibrate it compactly. After baking, it can be used. The rapid curing and baking refers to the curing of the material for 6-8 hours after hardening and demoulding, then raising the temperature to 150°C and keeping it warm for 6-8 hours; the...

Embodiment 2-9

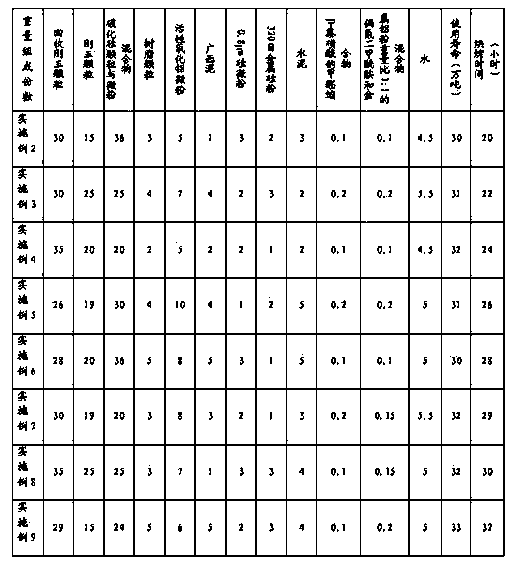

[0020] Embodiment 2-9: with reference to the manufacturing method described in embodiment 1, adjust the weight composition parts of raw material, concrete implementation data is as shown in Table 1:

[0021]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com