Compound microbial fertilizer prepared from papermaking sludge

A technology of composite microorganisms and papermaking sludge, which is applied to sewage/sludge fertilizers, organic fertilizers, fertilizer mixtures, etc., can solve the problems of composite microbial fertilizers that have not been found, and achieve the effects of improving utilization, improving soil, and promoting growth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] The wet sludge discharged from the paper mill was mechanically dehydrated to obtain 105kg of semi-dry sludge with a water content of 50%, and 0.2kg of Bacillus licheniformis was added for composting and fermentation to obtain 75kg of sludge with a water content of 30%, and then added 5kg of urea with 47% nitrogen (N), containing potassium oxide (K 2 O) 5kg of 60% potassium chloride, containing phosphorus pentoxide (P 2 o 5 ) 15kg of 18% calcium magnesium phosphate fertilizer was mixed evenly, and then mixed with 0.3kg of Bacillus licheniformis with a content of 20 billion / g to prepare 100kg of compound microbial fertilizer.

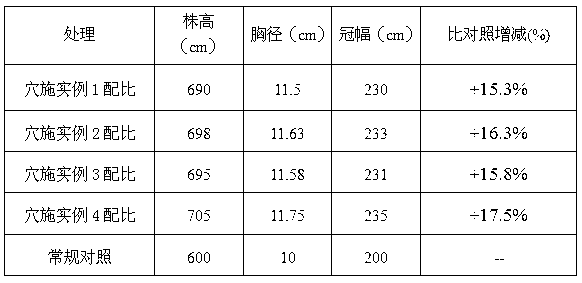

[0020] Using this compound microbial fertilizer to carry out the fertilizer effect test on the 2-year-old fast-growing Eucalyptus, the results show that the DBH growth of the fast-growing Eucalyptus has a significant difference compared with the blank control, and its fertilizer efficiency has increased by 15.3%.

Embodiment 2

[0022] The wet sludge discharged from the paper mill was mechanically dehydrated to obtain 84kg of semi-dry sludge with a water content of 40%, and 0.15kg of Bacillus licheniformis was added for composting fermentation to obtain 60kg of sludge with a water content of 30%, and then added 20kg of ammonium sulfate containing 46% nitrogen (N), containing potassium oxide (K 2 O) 60% potassium chloride 10kg, containing phosphorus pentoxide (P 2 o 5 ) 10kg of 18% monoammonium phosphate was mixed evenly, and then mixed with 0.3kg of Bacillus licheniformis with a content of 20 billion / g to prepare 100kg of compound microbial fertilizer.

[0023] Using this compound microbial fertilizer to carry out the fertilizer effect test on the 2-year-old fast-growing Eucalyptus, the results showed that the DBH growth of the fast-growing Eucalyptus was significantly different from that of the blank control, and its fertilizer efficiency increased by 16.3%.

Embodiment 3

[0025] The wet sludge discharged from the paper mill was mechanically dehydrated to obtain 98kg of semi-dry sludge with a water content of 50%, and 0.18kg of Bacillus licheniformis was added for composting and fermentation to obtain 70kg of sludge with a water content of 30%. 10kg of ammonium chloride containing 46% nitrogen (N), containing potassium oxide (K 2 O) 60% potassium sulfate 10kg, containing phosphorus pentoxide (P 2 o 5 ) 10kg of 18% monoammonium phosphate was mixed evenly, and then mixed with 0.3kg of Bacillus licheniformis with a content of 20 billion / g to prepare 100kg of compound microbial fertilizer.

[0026] Using this compound microbial fertilizer to carry out the fertilizer effect test on the 2-year-old fast-growing Eucalyptus, the results show that the DBH growth of the fast-growing Eucalyptus has a significant difference compared with the blank control, and its fertilizer efficiency has increased by 15.8%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com