Anti-skid coating

An anti-slip coating and coating technology, applied in the field of coatings, can solve the problems of unfriendly environment, affecting the appearance of buildings, and poor environmental performance of anti-slip materials, and achieve the effect of low price, excellent performance and easy construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

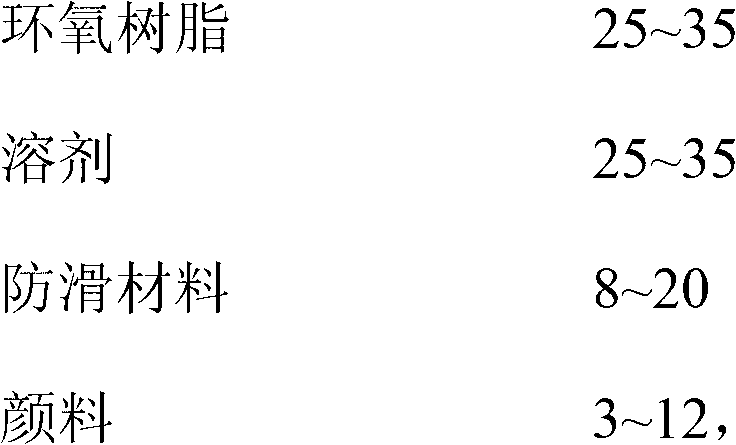

[0056] Described antiskid coating comprises by weight parts:

[0057]

[0058] Wherein, described curing liquid accounts for the weight percent of anticorrosion coating by its each component:

[0059] Polyamide resin 40%

[0060] Toluene 60%.

Embodiment 2

[0062] Described antiskid coating comprises by weight parts:

[0063]

[0064] Wherein, described curing liquid accounts for the weight percent of anticorrosion coating by its each component:

[0065] Polyamide resin 60%

[0066] Toluene 40%.

Embodiment 3

[0068] Described antiskid coating comprises by weight parts:

[0069]

[0070] Wherein, described curing liquid accounts for the weight percent of anticorrosion coating by its each component:

[0071] Polyamide resin 50%

[0072] Toluene 50%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com