Analysis of Ar and O2, N2, CO2 and N2O in atmospheric air through one-time sampling with gas phase chromatography

A technology of gas chromatography and CO2, which is applied to the analysis of materials, material separation, and measurement devices, can solve the problems of large data accuracy errors and prolong the sample measurement cycle, so as to reduce data accuracy errors, shorten the sample measurement cycle, and easily The effect of the operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

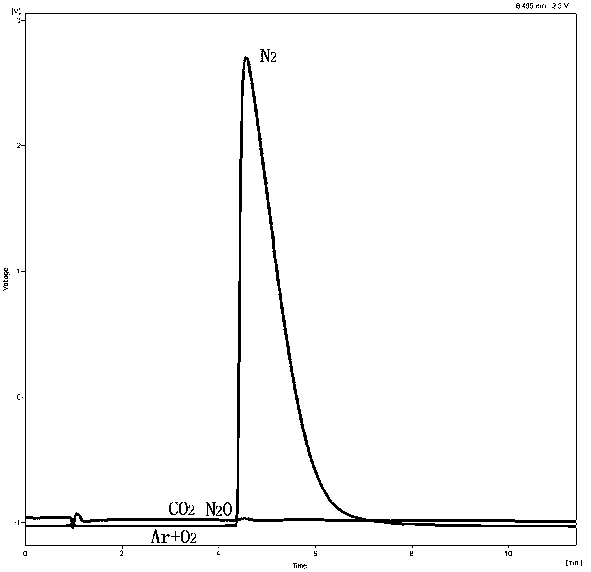

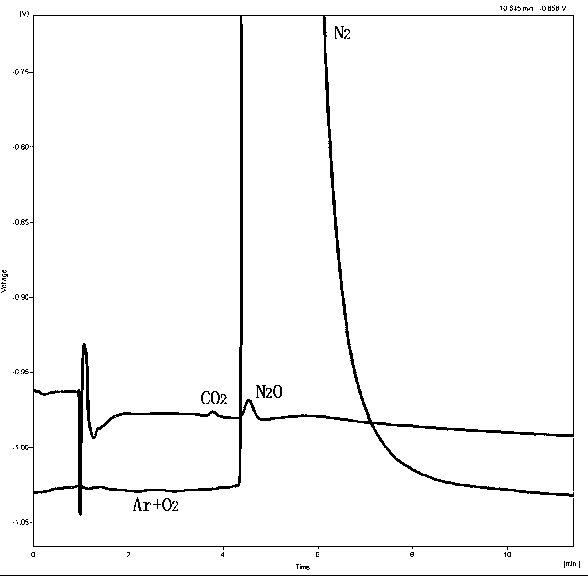

[0028] Example 1 like figure 1 Shown, gas chromatography one injection analysis of Ar+O in the atmosphere 2 , N 2 , CO 2 , N 2 O, first pass the carrier gas with a purity greater than 99.999% through the purifier at an output pressure of 0.20 MPa, so that the purity of the purified carrier gas is greater than 99.9999% or greater than 99.99999%; then pass the purified carrier gas at a flow rate of 15ml / min, At a temperature of 25°C, pass through the chromatographic column in the gas chromatograph where the sample to be tested has been placed In , after adsorption and desorption at a temperature of 25°C, the Ar+O in the sample to be tested 2 , N 2 , CO 2 , N 2 O enters the electron capture detector (ECD) to detect CO at a temperature of 90 °C 2 , N 2 O, and the data detected by the electron capture detector (ECD) are input to the chromatographic workstation in the gas chromatograph; at the same time, the carrier gas and the Ar+O in the sample to be tested 2 , N...

Embodiment 2

[0032] Example 2 like figure 1Shown, gas chromatography one injection analysis of Ar+O in the atmosphere 2 , N 2 , CO 2 , N 2 O, first pass the carrier gas with a purity greater than 99.999% through the purifier at an output pressure of 0.60 MPa, so that the purity of the purified carrier gas is greater than 99.9999% or greater than 99.99999%; then pass the purified carrier gas at a flow rate of 75ml / min, At a temperature of 50°C, it is passed into the chromatographic column of the gas chromatograph where the sample to be tested has been placed In , after adsorption and desorption at a temperature of 250°C, the Ar+O in the sample to be tested 2 , N 2 , CO 2 , N 2 O enters the electron capture detector (ECD) to detect CO at a temperature of 350 °C 2 , N 2 O, and the data detected by the electron capture detector (ECD) are input to the chromatographic workstation in the gas chromatograph; at the same time, the carrier gas and the Ar+O in the sample to be tested ...

Embodiment 3

[0036] Example 3 like figure 1 Shown, gas chromatography one injection analysis of Ar+O in the atmosphere 2 , N 2 , CO 2 , N 2 O, first pass the carrier gas with a purity greater than 99.999% through the purifier at an output pressure of 0.40 MPa, so that the purity of the purified carrier gas is greater than 99.9999% or greater than 99.99999%; then pass the purified carrier gas at a flow rate of 45ml / min, At a temperature of 35°C, pass through the chromatographic column in the gas chromatograph where the sample to be tested has been placed In , after adsorption and desorption at a temperature of 100°C, the Ar+O in the sample to be tested 2 , N 2 , CO 2 , N 2 O enters an electron capture detector (ECD) to detect CO at a temperature of 220 °C 2 , N 2 O, and the data detected by the electron capture detector (ECD) are input to the chromatographic workstation in the gas chromatograph; at the same time, the carrier gas and the Ar+O in the sample to be tested 2 , ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

| Column length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com