Conductive high polymer catholyte solution as well as preparation method and application thereof

A technology of conductive polymers and electrolyte solutions, applied in electrolytic capacitors, solid electrolytic capacitors, circuits, etc., can solve problems such as high ESR, achieve good impedance frequency characteristics, good high temperature thermal stability, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

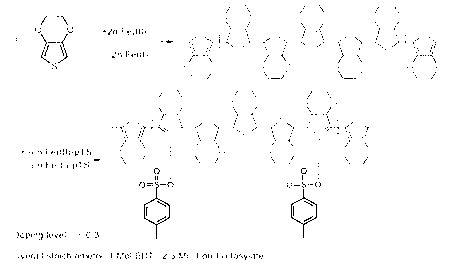

Method used

Image

Examples

Embodiment 1

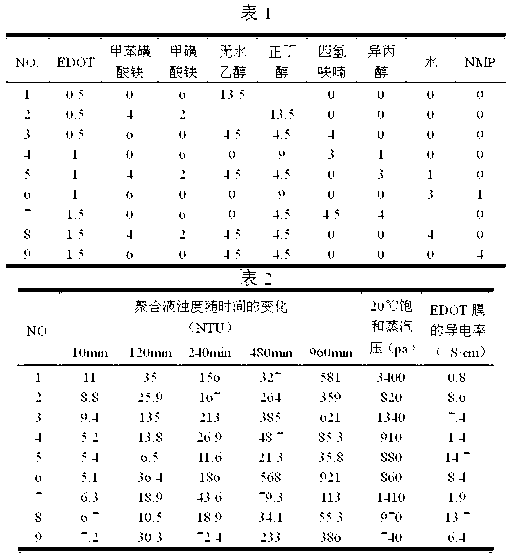

[0053] According to the proportions listed in Table 1 below, first dissolve the listed iron (III) tosylate and / or iron (III) methanesulfonate with absolute ethanol and / or n-butanol to form an oxidant solution, and then other solvents Mix, add 3,4-ethylenedioxythiophene (EDOT) monomer to form a monomer solution, then mix the prepared oxidant solution and monomer solution, and oscillate with ultrasonic waves to make the solution fully mixed evenly. 20°C) to measure the saturated vapor pressure of the mixed solution. The saturated vapor pressure of the mixed solution was measured at room temperature (20°C), and the turbidity of the polymerization liquid was measured over time. The results are shown in Table 2.

[0054] For each prepared polymerization solution, carry out the oxidative polymerization test according to the following steps respectively:

[0055] 1) Clean the 20×50mm glass slide with deionization and dry it. After the slides are cooled to room temperature, immerse ...

Embodiment 2

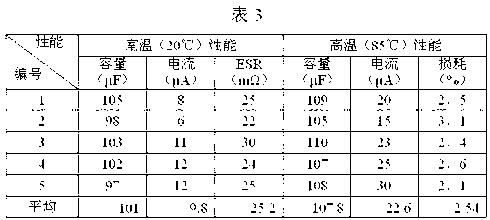

[0062] Select tantalum powder with a CV value of 70,000μFV / g, add anode-grade tantalum wire, press it into a 4.3×3.1×0.8 (mm) pellet, and sinter the porous anode body at a high temperature and high vacuum at 1290°C. The anode body is anodized to 54V in dilute phosphoric acid aqueous solution to form a dielectric oxide film layer, and then the root of the anode lead is coated with silica gel, and the prepared porous anode body is immersed in a solution containing a protective binder, ( The solution consists of an aqueous solution containing 1% by weight of polyvinyl alcohol and 1% by weight of ethylenediaminetetraacetic acid (EDTA), while applying a forward voltage of 20V to the anode block, and taking out the anode block after 10 minutes. Stand at room temperature for 10-15 minutes, and then dry at a temperature of 140-160°C for 20 minutes.

[0063] According to the 5# formula in Example 1, the polymerization solution (A, B liquid) was prepared according to the above-mentioned...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com