Bragg reflection waveguide double-beam laser and application method thereof

A Bragg reflection, double beam technology, applied in semiconductor lasers, lasers, laser parts and other directions, can solve the problems of difficult to stabilize the output power of the device, complex optical alignment, difficult to mass production, etc., to achieve compactness and high stability , large laser cavity, the effect of improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

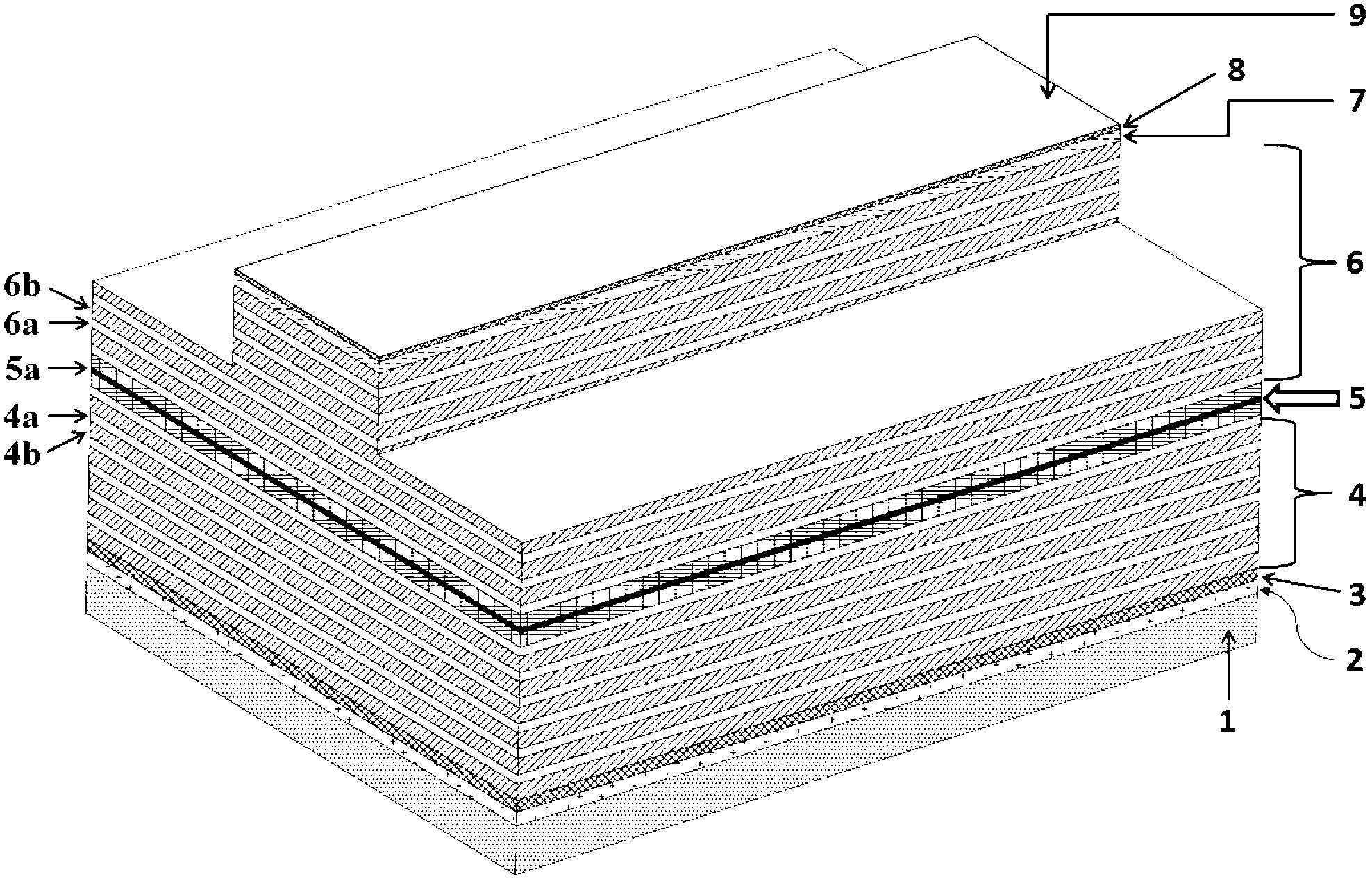

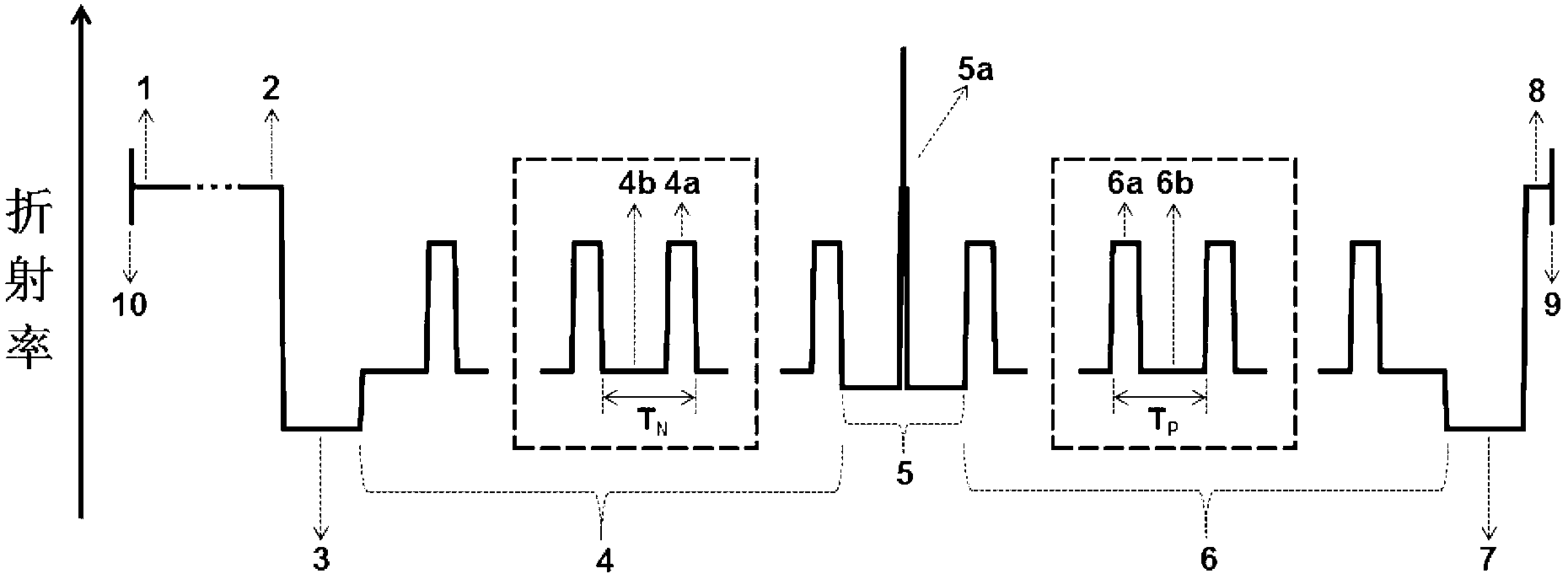

[0041] Such as Figure 4 (a), (b) and (c) are schematic diagrams of the refractive index distribution, near-field and far-field intensity distribution of the fundamental transverse mode of a 980nm wavelength Bragg reflective waveguide dual-beam laser. Its lower waveguide layer and upper waveguide layer are made of 6 pairs of Al with a thickness of 100nm / 600nm respectively. 0.1 Ga 0.9 As / Al 0.3 Ga 0.7 As periodic waveguide, where Al 0.1 Ga 0.9 As and Al 0.3 Ga 0.7 The refractive index of the As material is about 3.45 and 3.34 respectively; the material of the defect layer is Al 0.3 Ga 0.7 As, the thickness is 1300nm, the refractive index is 3.34; the active area uses In 0.2 Ga 0.8 As / GaAs quantum wells (QWs), located in the center of the defect layer. From Figure 4 (b) The near-field intensity distribution of the fundamental mode in (b) It can be seen that the near-field electric field distribution of the fundamental mode of the laser in the present invention is cl...

Embodiment 2

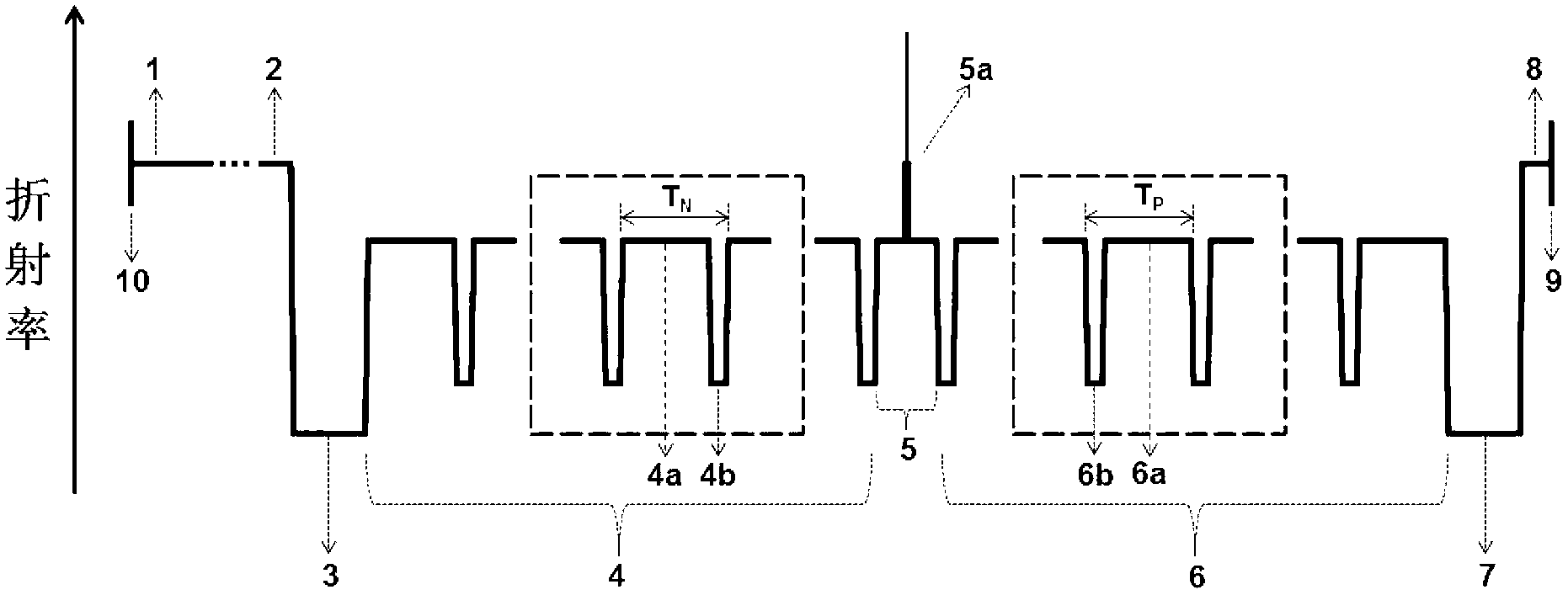

[0043] Such as Figure 5 (a), (b) and (c) are schematic diagrams of the refractive index distribution, near-field and far-field intensity distribution of the fundamental transverse mode of a 980nm wavelength Bragg reflective waveguide dual-beam laser. Its lower waveguide layer and upper waveguide layer are made of 6 pairs of Al with a thickness of 100nm / 600nm respectively. 0.35 Ga 0.65 As / Al 0.1 Ga 0.9 As periodic waveguide, where Al 0.35 Ga 0.65 As and Al 0.1 Ga 0.9 The refractive index of the As material is 3.31 and 3.45 respectively; the material of the defect layer is Al 0.1 Ga 0.7 As, the thickness is 400nm, the refractive index is 3.45; the active area uses In 0.2 Ga 0.8 As / GaAs quantum wells (QWs). From Figure 4 (b) The near-field intensity distribution of the fundamental mode shows that even if the defect layer is made of a high-refractive material, by reducing its thickness, a near-field electric field distribution close to the cosine function can be obta...

Embodiment 3

[0045] Such as Figure 6 (a), (b), and (c) are schematic diagrams of the refractive index distribution, near-field and far-field intensity distribution of the fundamental transverse mode of an 850nm wavelength Bragg reflective waveguide dual-beam laser. Its lower waveguide layer and upper waveguide layer are made of 8 pairs of Al with a thickness of 200nm / 500nm respectively. 0.15 Ga 0.85 As / Al 0.3 Ga 0.7 As periodic waveguide, where Al 0.15 Ga 0.85 As and Al 0.3 Ga 0.7 The refractive index of As material at 850nm wavelength is about 3.5 and 3.4 respectively; the defect layer material is 1μm thick Al 0.35 Ga 0.65 As, the refractive index is about 3.37. From Figure 6 (b) It can be seen that when the lower confinement layer and the upper confinement layer do not exist, a stronger optical field confinement can still be obtained by increasing the period logarithm of the Bragg mirror, so that the leakage loss of the laser can be kept at a low level.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com