Preparation method of graphene-based novel nano magnetic biological adsorbent

A nano-magnetic and graphene technology, applied in chemical instruments and methods, adsorption of water/sewage treatment, alkali metal compounds, etc., can solve the problems of long adsorption equilibrium time, limited adsorption capacity, poor mechanical properties, etc., and achieve improved adsorption Effects of speed and adsorption capacity, improvement of adsorption capacity, and enhancement of mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

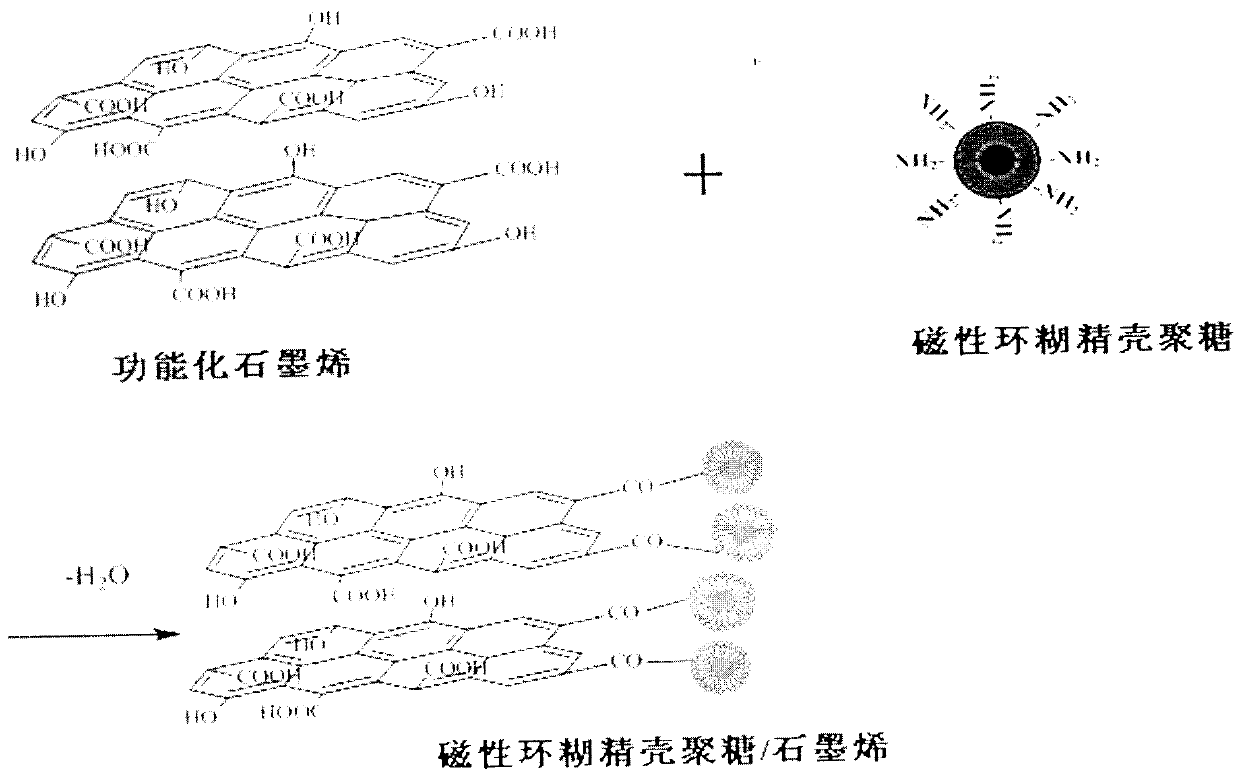

[0022] Example 1: Preparation of magnetic cyclodextrin chitosan / graphene adsorption material

[0023] A. Preparation of functionalized graphene

[0024] Weigh 1.0g of graphite powder and add it to 200mL mixed acid (volume ratio of concentrated nitric acid to concentrated sulfuric acid: 1:6) (in an ice-water bath, add nitric acid first and then sulfuric acid under stirring), stir and react for 0.5h, then add 6.0g permanganese Potassium acid, oil bath 80 ° C, heated to reflux, and reacted for 12 hours. Under ice-bath conditions, slowly add hydrogen peroxide dropwise until no more reaction occurs, centrifuge, wash with dilute hydrochloric acid and ethanol in sequence, and dry to obtain functionalized graphene.

[0025] B. Preparation of Magnetic Cyclodextrin Chitosan

[0026] Dissolve 6.0g of cyclodextrin and 1.0g of chitosan in hydrochloric acid solution, stir for 0.2h to obtain a milky white solution, add 3mL of 50% glutaraldehyde, react at 70°C for 1h, adjust the pH to 7-8, ...

example 2

[0030] Example 2: Preparation of magnetic cyclodextrin chitosan / graphene adsorption material

[0031] A. Preparation of functionalized graphene

[0032] Weigh 1.0g of graphite powder and add it to 200mL of mixed acid (volume ratio of concentrated sulfuric acid to concentrated nitric acid: 1:8) (in an ice-water bath, add nitric acid first and then sulfuric acid under stirring), stir and react for 0.8h, then add 7.0g permanganese Potassium acid, oil bath 85 ° C, heated to reflux, and reacted for 13 hours. Under ice-bath conditions, slowly add hydrogen peroxide dropwise until no more reaction occurs, centrifuge, wash with dilute hydrochloric acid and ethanol in sequence, and dry to obtain functionalized graphene.

[0033] B. Preparation of Magnetic Cyclodextrin Chitosan

[0034] Dissolve 8.0g of cyclodextrin and 1.0g of chitosan in hydrochloric acid solution, stir for 0.3h to obtain a milky white solution, add 4mL of 50% glutaraldehyde, react at 75°C for 1h, adjust the pH to 7-...

example 3

[0038] Example 3: Preparation of magnetic cyclodextrin chitosan / graphene adsorption material

[0039] A. Preparation of functionalized graphene

[0040] Weigh 1.0g of graphite powder and add 200mL of mixed acid (volume ratio of concentrated sulfuric acid to concentrated nitric acid: 1:9) (in an ice-water bath, add nitric acid first and then sulfuric acid under stirring), stir for 1 hour, then add 8.0g of potassium permanganate , oil bath at 95°C, heated to reflux, and reacted for 15h. Under ice-bath conditions, slowly add hydrogen peroxide dropwise until no more reaction occurs, centrifuge, wash with dilute hydrochloric acid and ethanol in sequence, and dry to obtain functionalized graphene.

[0041] B. Preparation of Magnetic Cyclodextrin Chitosan

[0042] Dissolve 9.0g of cyclodextrin and 1.0g of chitosan in hydrochloric acid solution, stir for 0.3h to obtain a milky white solution, add 6mL of 50% glutaraldehyde, react at 90°C for 2h, adjust the pH to 7-8, filter , and dry ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com