Technique for strengthening local surface of engine piston

A technology of surface strengthening and process method, applied in the direction of engine components, machines/engines, pistons, etc., can solve the problems of difficult to change thermal expansion performance, large thermal expansion coefficient, small thermal expansion coefficient, etc., to improve hardness and wear resistance, good Service performance, the effect of reducing the thermal expansion coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

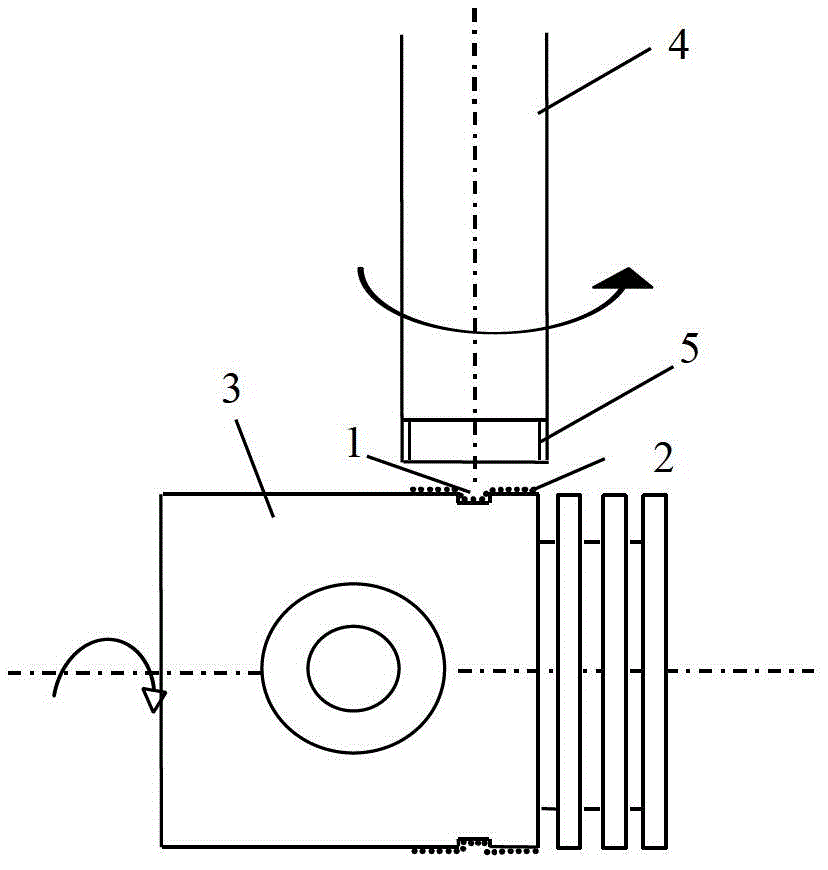

[0032] Example 1 (see figure 1 ):

[0033] (1) The alloy material of the magnesium alloy engine piston 3 is Mg-15Gd-2.5Zn-0.6Zr (wt.%), and the surface of the piston 3 is cleaned and pretreated after the piston 3 is solid solution treated.

[0034] (2) A concave groove 1 with a width of 30 mm and a depth of 1.0 mm is formed on the surface of the skirt of the engine piston 3 in the circumferential direction with a lathe.

[0035] (3) On the skirt of the engine piston 3 and the concave groove 1, the high-hard wear-resistant layer 2 is sprayed by plasma spraying, and a ceramic coating with a thickness of 0.2mm is formed on the surface of the piston 3. The spraying material is 50μm in diameter. Al 2 O 3 -TiO 2 50% mixed particles.

[0036] (4) Clamp the engine piston 3 on the rotating shaft of the friction stir welding machine with adjustable speed, and align the stirring head of the friction stir welding machine with the starting point of the concave groove 1 of the piston 3 to be proces...

Embodiment 2

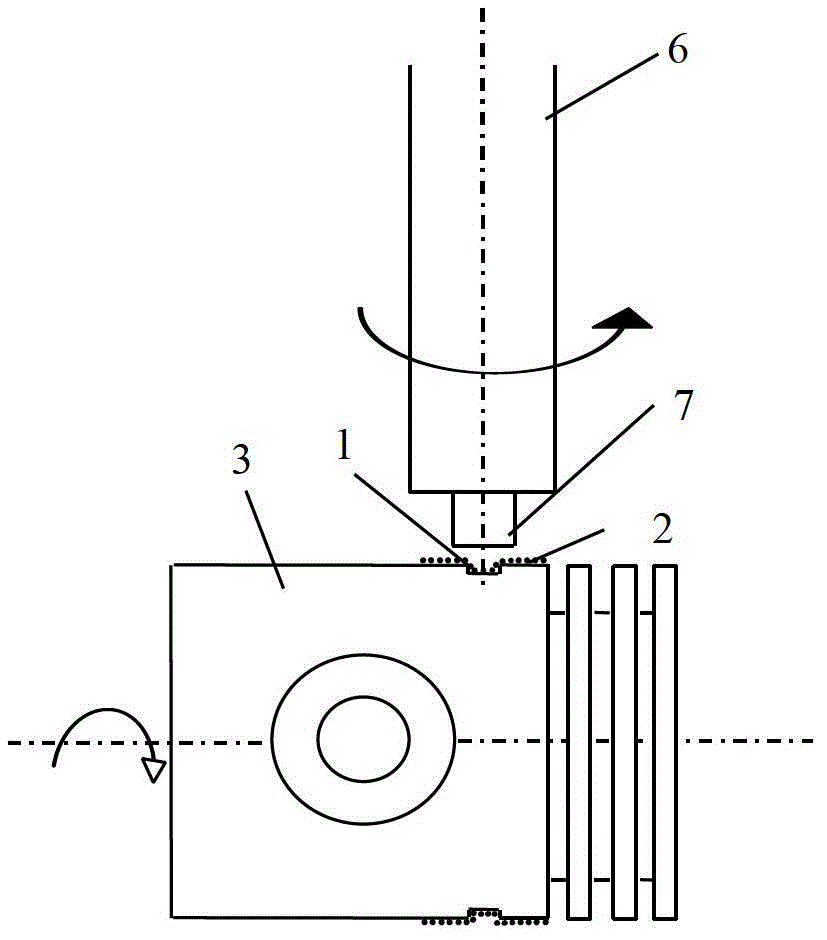

[0040] Example 2 (see figure 2 ):

[0041] (1) The alloy material composition of the magnesium alloy engine piston 3 is Mg-10Gd-3Y-2Zn-0.4Zr (wt.%). The casted piston 3 is solid-dissolved at 525°C for 15 hours, and after air cooling, the piston 3 The surface is cleaned and pretreated.

[0042] (2) Use a lathe to make a concave groove 1 with a width of 20 mm and a depth of 0.2 mm on the skirt of the engine piston 3 in the circumferential direction;

[0043] (3) At the skirt of the engine piston 3 and the concave groove 1, the high-hard wear-resistant layer 2 is sprayed by flame spraying, and a ceramic coating with a thickness of 0.1mm is formed on the surface of the piston 3. The spraying material is 100μm in diameter. SiC particles.

[0044] (4) Clamp the engine piston 3 on the rotating shaft of the friction stir welding machine with adjustable speed, and align the stirring head of the friction stir welding machine with the starting point of the concave groove 1 of the piston 3 to b...

Embodiment 3

[0048] (1) The alloy material composition of the aluminum alloy engine piston is Al-13Si-3Cu-2Ni-1.0Mg (wt.%), and the surface of the piston is cleaned and pretreated after the casting of the piston is solid solution treated.

[0049] (2) Use a lathe to cut a concave groove with a width of 2mm and a depth of 0.25mm in the circumferential direction of the skirt of the engine piston;

[0050] (3) At the piston skirt and concave groove of the engine, the high-hard wear-resistant layer is sprayed by thermochemical reaction thermal spraying to form a ceramic coating with a thickness of 0.28mm on the piston surface. The spraying material is commercial Al 2 O 3 , TiO 2 , SiO 2 A mixed powder of five substances, ZnO and Al, the particle size of the mixed powder is 200nm.

[0051] (4) Clamp the engine piston on the rotating shaft of the friction stir welding machine with adjustable speed to align the stirring head with the starting point of the concave groove of the piston to be processed; the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com