Method for preparing three-dimensional hierarchical porous carbon

A technology of hierarchical porous carbon and carbon source, applied in the direction of carbon preparation/purification, nanotechnology, etc., to achieve the effect of simple preparation process, low cost and simple equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

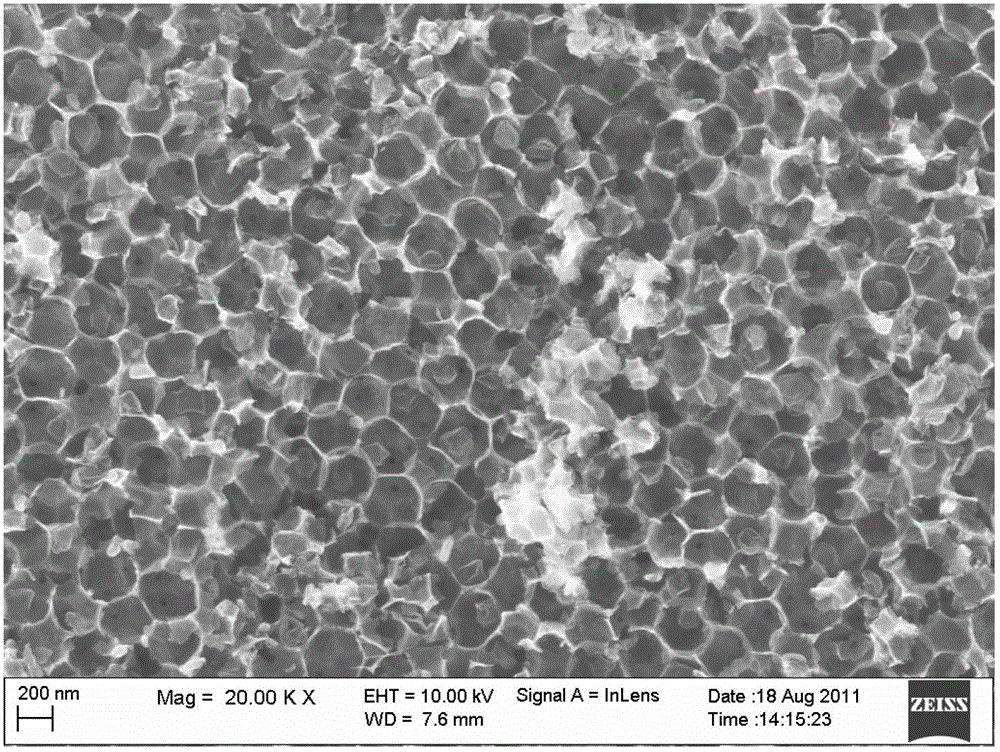

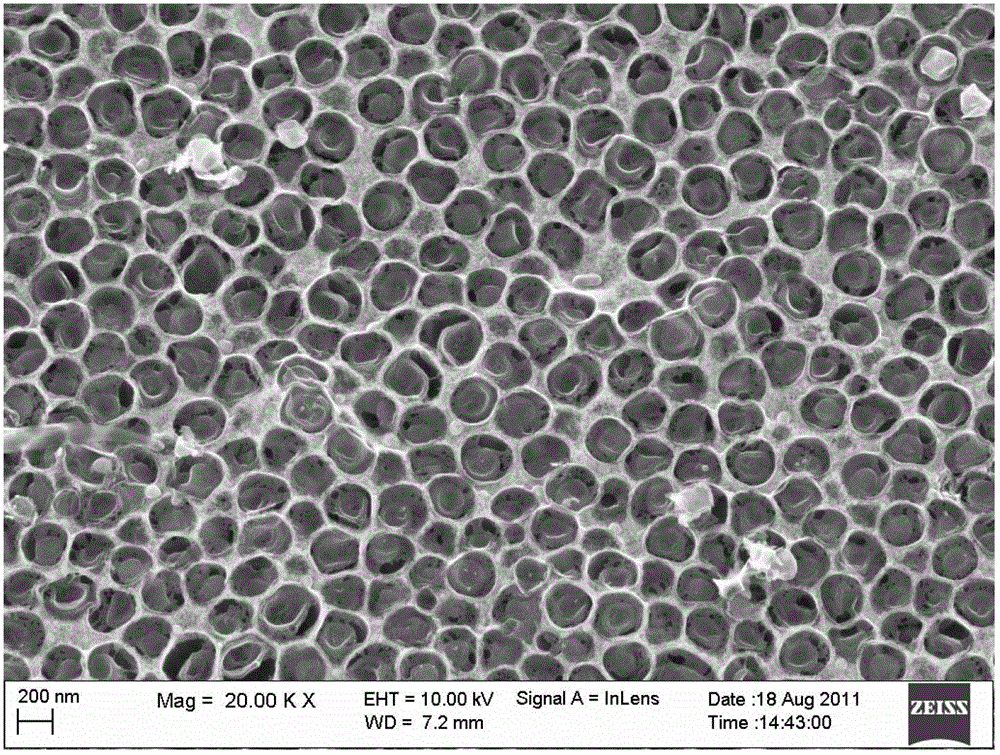

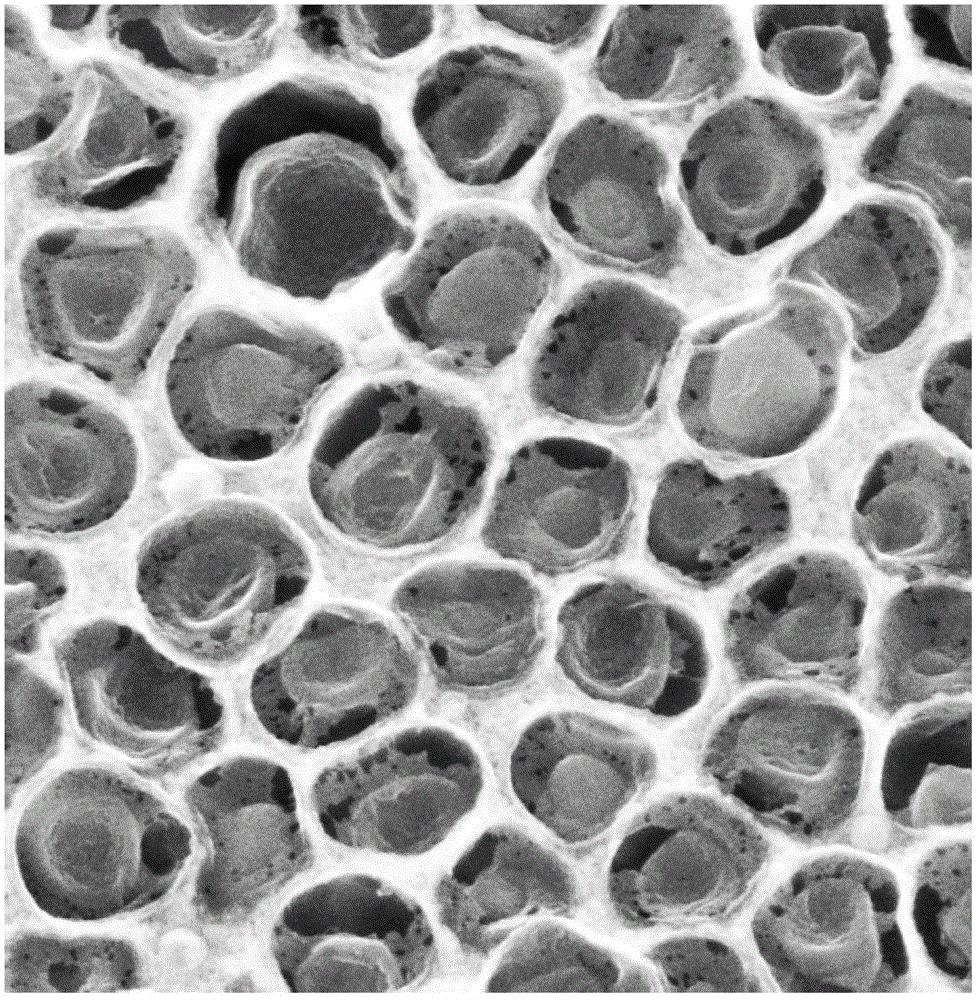

[0022] Preparation of 3D hierarchical porous carbon. Weigh 3.88g resorcinol and 5.2ml formaldehyde, mix and stir for 1 hour, add 15ml deionized water, mix and stir for 2 hours to form a uniform mixed solution as the carbon source precursor solution. Weigh 10g of tetraethyl orthosilicate, 5g of ethanol, 5g of deionized water, 1g of hydrochloric acid (1mol / L) and mix well, then stir and mix with the carbon source precursor solution. Take 10 g of dried hollow polystyrene microsphere colloidal crystals and place them in a beaker, slowly add the above-mentioned carbon source-silicon source mixed solution to the beaker until the solution is close to the top of the colloidal crystals, then seal it, and place it at room temperature for 48 hours. until the gel is complete. Remove the part without colloidal crystals in the gel, dry at 75°C, then put the product into a high-temperature atmosphere furnace, pass in argon gas at a rate of 0.1L / min, raise the temperature to 105°C at a rate ...

Embodiment 2

[0024] Preparation of 3D hierarchical porous carbon. Weigh 7.76g resorcinol and 11ml formaldehyde, mix and stir for 1 hour, add 15ml deionized water, mix and stir for 2 hours to form a uniform mixed solution as the carbon source precursor solution. Weigh 10g of tetraethyl orthosilicate, 5g of ethanol, 5g of deionized water, 1g of hydrochloric acid (1mol / L) and mix well, then stir and mix with the carbon source precursor solution. Take 10 g of dry hollow polystyrene microsphere colloidal crystals and place them in a beaker, slowly add the above-mentioned carbon source-silicon source mixed solution to the beaker until the solution is close to the top of the colloidal crystals, then seal it, and place it at room temperature for 60 hours. until the gel is complete. Remove the part without colloidal crystals in the gel, dry at 60°C, then put the product into a high-temperature atmosphere furnace, pass in argon gas at a rate of 0.1L / min, raise the temperature to 100°C at a rate of ...

Embodiment 3

[0026] Preparation of 3D hierarchical porous carbon. Weigh 7.76g resorcinol and 11ml formaldehyde, mix and stir for 1 hour, add 30ml deionized water, mix and stir for 1 hour, add 15ml deionized water, mix and stir for 2 hours to form a uniform mixed solution as the carbon source precursor solution. Weigh 10g of tetraethyl orthosilicate, 5g of ethanol, 5g of deionized water, 1g of hydrochloric acid (1mol / L) and mix well, then stir and mix with the carbon source precursor solution. Take 10 g of dried hollow polystyrene microsphere colloidal crystals and place them in a beaker, slowly add the above-mentioned carbon source-silicon source mixed solution to the beaker until the solution is close to the top of the colloidal crystals, then seal it, and place it at room temperature for 48 hours. until the gel is complete. Remove the part without colloidal crystals in the gel, dry at 65°C, then put the product into a high-temperature atmosphere furnace, pass in argon gas at a rate of 0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com