Organic carrier for electronic silver paste and preparation method of organic carrier

An organic carrier, silver paste technology, applied in conductive materials dispersed in non-conductive inorganic materials, etc., can solve the problems of disconnection and inequality, and achieve improved surface quality, good consistency, and good compatibility. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] An organic vehicle for electronic silver paste, which is composed of a thickener, a solvent and an auxiliary agent, the auxiliary agent includes a surfactant, a coupling agent, a plasticizer and a defoamer, and the thickener is ethyl cellulose and Phenolic resin, solvent is terpineol, butyl carbitol, surfactant is zinc stearate, coupling agent is titanate coupling agent TTOP-12, plasticizer is dibutyl phthalate, The defoamer is polyoxypropylene propylene glycol ether, and the components are as follows by weight percentage: ethyl cellulose 4.5%, phenolic resin 2.0%, terpineol 50.0%, butyl carbitol 32.3%, stearate Zinc acid 1.0%, titanate coupling agent TTOP-12 1.5%, dibutyl phthalate 7.5%, polyoxypropylene propylene glycol ether 1.2%.

[0028] The preparation method of the organic carrier for the above-mentioned electronic silver paste specifically comprises the following steps:

[0029] (1) Weigh various raw materials according to the weight percentage of each componen...

Embodiment 2

[0034] An organic vehicle for electronic silver paste, which is composed of a thickener, a solvent and an auxiliary agent, the auxiliary agent includes a surfactant, a coupling agent, a plasticizer and a defoamer, and the thickener is ethyl cellulose and Rosin resin, solvent is terpineol, butyl carbitol, surfactant is zinc stearate, coupling agent is titanate coupling agent TTOP-12, plasticizer is dioctyl phthalate, The defoamer is polyoxypropylene propylene glycol ether, and the components are as follows: ethyl cellulose 8.0%, rosin resin 1.0%, terpineol 71.0%, butyl carbitol 9.0%, stearate Zinc acid 1.5%, titanate coupling agent TTOP-12 1.0%, dioctyl phthalate 7.5%, polyoxypropylene propylene glycol ether 1.0%.

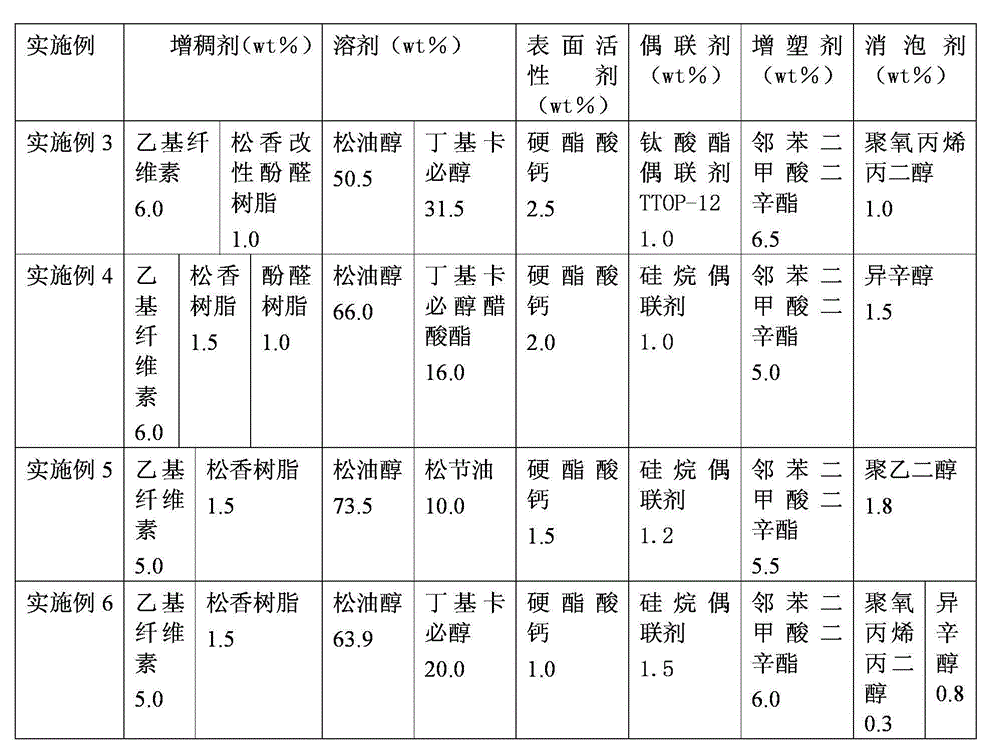

[0035] The components and weight percentages of the organic vehicle in Examples 3-6 are shown in Table 1.

[0036] Table 1 Different ratios of organic carriers

[0037]

[0038] The organic carrier prepared by 20% of Examples 1-6 and 75% silver powder, 3% boron...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com