Special jet ink for PVC (polyvinyl chloride) cable

A coding and ink technology, which is applied in the field of special coding ink for PVC cables and its preparation, can solve the problems of limited application and inability to solve the problems of PVC cable bonding and durability of nozzles at the same time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

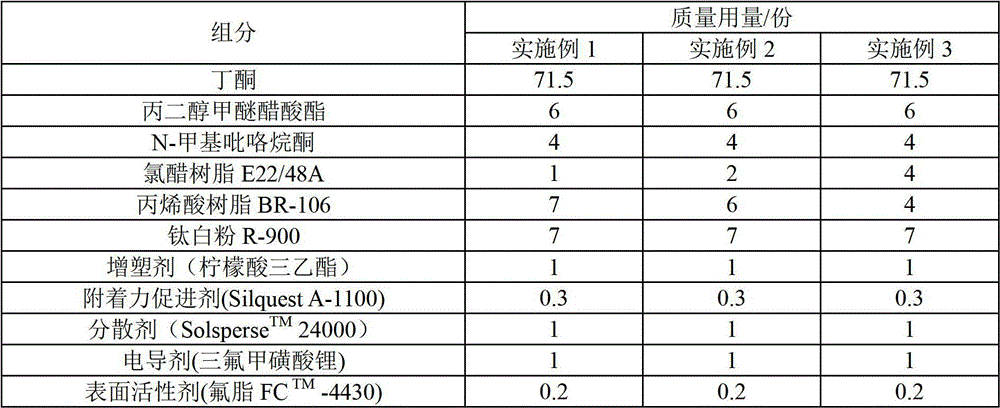

Embodiment 1-3

[0044] According to the formula in Table 1, the special inkjet ink for PVC cables was prepared by the following method: first mix methyl ethyl ketone, propylene glycol methyl ether acetate and N-methylpyrrolidone according to the recipe amount, and then make an organic solvent mixture. Then add the hydroxyl group-containing vinyl acetate resin E22 / 84A (Wacker Chemical, Germany) and acrylic resin BR-106 (Mitsubishi, Japan) into the above part of the organic solvent mixture, stir and dissolve at room temperature (25°C), A binder resin mixed solution was prepared. Secondly, titanium dioxide R-900 (DuPont, USA) was added to the organic solvent mixture of the remaining formulation amount, stirred and dispersed at room temperature (25°C) to obtain a colorant mixture. Finally, mix the above-mentioned adhesive resin mixture and colorant mixture evenly at room temperature, and add the recipe amount of triethyl citrate, Silquest A-1100 (Momentive, USA), Solsperse TM 24000 (Lubrizol, U...

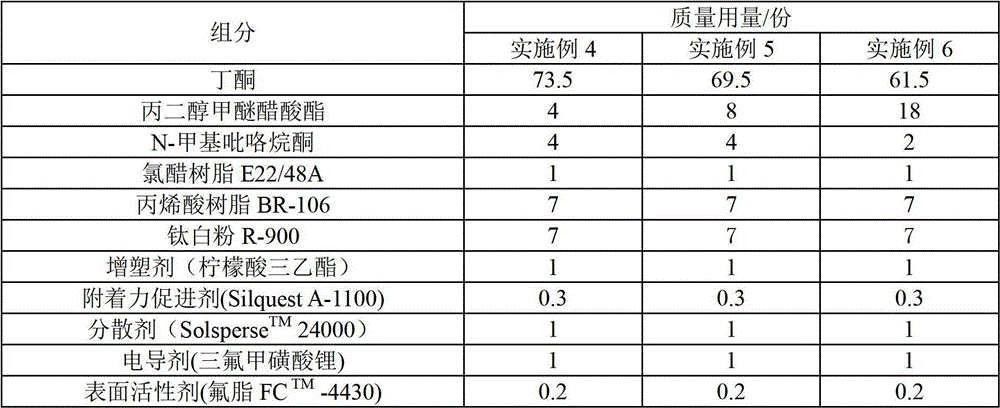

Embodiment 4-6

[0050] According to the formula in Table 3, the special inkjet ink for PVC cables was prepared by the following method: first mix methyl ethyl ketone, propylene glycol methyl ether acetate and N-methylpyrrolidone according to the recipe amount, and then make an organic solvent mixture. Then add the hydroxyl-containing vinyl vinyl resin E22 / 48A and acrylic resin BR-106 into the above-mentioned organic mixed solution of the remaining recipe amount, stir and dissolve at room temperature (25°C) to obtain a binder resin mixed solution . Next, add titanium dioxide R-900 to the mixed solvent of the remaining recipe amount, stir and disperse at room temperature (25°C) to prepare a colorant mixed solution. Finally, mix the above-mentioned adhesive resin mixed solution and colorant mixed solution at room temperature, and add triethyl citrate, Silquest A-1100, Solsperse TM 24000, lithium trifluoromethanesulfonate and fluorine grease FC TM -4430, stirring, grinding with a nanometer hor...

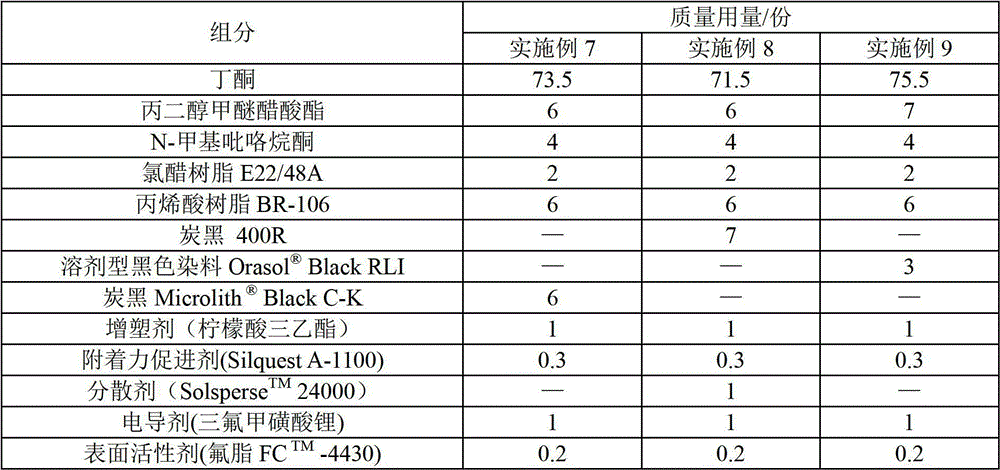

Embodiment 7-9

[0056] According to the formula in Table 5, the special inkjet ink for PVC cables was prepared by the following method: first mix butanone, propylene glycol methyl ether acetate and N-methylpyrrolidone according to the recipe amount to make a mixed solvent. Then add the hydroxyl group-containing vinyl vinyl resin E22 / 48A and acrylic resin BR-106 into the above-mentioned part of the organic solvent mixture, stir and dissolve at room temperature to obtain a binder resin mixture solution. Second, the carbon black Black C-K (BASF-Ciba, Germany) and / or carbon black 400R (Cabot Chemical, USA) and / or solvent-based black dye Add Black RLI (BASF-Ciba, Germany) to the remaining amount of the organic solvent mixture, stir and disperse at room temperature to prepare the colorant mixture. Finally, mix the binder resin mixed solution and the colorant mixed solution evenly, add triethyl citrate, Silquest A-1100, Solsperse TM 24000, lithium trifluoromethanesulfonate and fluorine grease FC ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com