Phase stabilizer and methanol gasoline added with phase stabilizer

A phase stabilizer, methanol gasoline technology, applied in fuel additives, petroleum industry, fuel, etc., can solve the problems of complex additive components, unstable properties, and high synthesis cost, so as to achieve easy mastery of operation technology and overcome water absorption and easy stratification , The effect of low equipment investment cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Formaldehyde solution 300g, ethylene glycol 250g, Nafion Add 10 g of SAC-13 superacid (decalin perfluorinated ion exchange resin, Bailingwei Technology) into the reactor, replace the air in the reactor with nitrogen, raise the temperature to 115°C under stirring, react for 2 hours, and then naturally cool to room temperature.

[0028] The liquid is distilled at 70-78°C to collect fractions, continue to heat up to 120°C to separate a small amount of by-products, and return the remaining undistilled liquid to the reactor to add raw materials to continue the reaction. The collected azeotropic fraction at 70-78°C is rectified by adding salt to obtain an alkylene oxide compound (phase stabilizer) with a water content below 100ppm. The product properties are shown in Table 1.

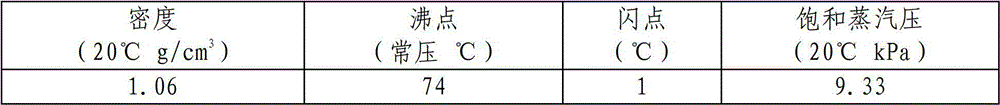

[0029] Table 1 Properties of the synthesized alkylene oxide compounds

[0030]

Embodiment 2

[0032] 120g of paraformaldehyde, mixed glycol (the main components are 1,2-propanediol 43%, ethylene glycol 15%, 1,2-butanediol 4%, 1,2-pentanediol 2% and Add 250g of 1,2-hexanediol, the rest is water) and 10g of phosphotungstic acid into the reaction kettle, replace the air in the kettle with nitrogen, raise the temperature to 135°C under stirring conditions, react for 4 hours, and then naturally cool to room temperature.

[0033] Liquid atmospheric distillation collects fractions at 70-85°C, continues to heat up to 140°C to remove a small amount of by-products in the reaction liquid, and returns the remaining undistilled liquid to the reactor to adjust the ratio of raw materials to continue the reaction. The collected azeotropic fraction at 70-85°C was rectified to obtain a mixture containing alkylene oxide compound (phase stabilizer) with a water content below 100ppm, and the product weighed 180g.

Embodiment 3

[0035] Add 10g of sodium nitrite, 14g of N,N-disalicylidene propylenediamine and 20g of dimethyl carbonate into 60mL of acetone, and stir until completely dissolved. Add to the mixture containing alkylene oxide compound (phase stabilizer) mentioned in Example 2, stir until uniformly mixed to obtain a mixture of phase stabilizer, preservative and cleaning agent, and keep it sealed.

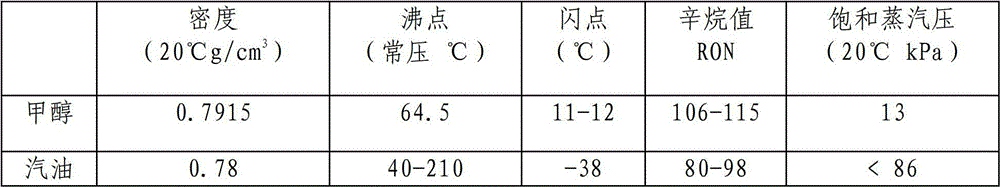

[0036] 93 # Pure gasoline and methanol are mixed in the reactor according to the mass ratio of 65:35, and the air in the reactor is replaced by nitrogen, and the mixture of the above-mentioned phase stabilizer, preservative and cleaning agent accounting for 10% of the mass of the mixed oil is slowly added under stirring conditions, and continuously Stir to obtain finished methanol gasoline. The physical and chemical properties of methanol and gasoline are shown in Table 2.

[0037] Table 2 Common physical and chemical properties of methanol and gasoline

[0038]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com