Productive technology of environment-friendly type solid welding wires without copper facing

A technology of solid welding wire and production process, which is applied in the direction of metal material coating process, welding medium, manufacturing tools, etc., can solve the problems of high pre-processing and post-processing requirements for semi-finished products, difficulty in popularization and application, and high cost, etc., to achieve production Low cost, smooth surface of welding wire, and clean surface effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

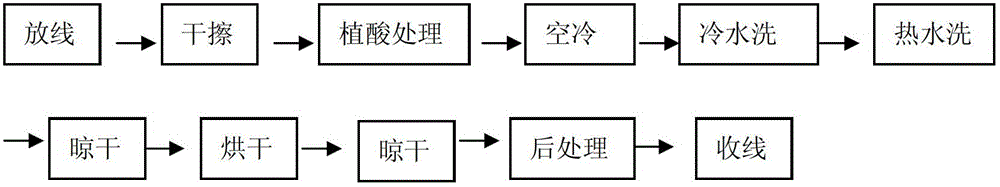

[0049] The production process of environmentally-friendly non-copper-plated solid welding wire includes an offline hydrochloric acid washing process of welding wire raw materials, a drawing process and a copper-free process; the copper-free process includes a phytic acid treatment step and a post-treatment step:

[0050] 1. The off-line hydrochloric acid washing process of welding wire raw material (steel): successively including pickling, water rinsing and neutralization washing steps:

[0051] Pickling-water rinsing-neutralization washing.

[0052] During the pickling, a hydrochloric acid solution with a concentration of 5-10% by weight is used to clean the surface of the welding wire raw material, and the Fe in the solution after the pickling 2+ The concentration of the welding wire is controlled to be ≤200g / L; the time to soak the raw material of the welding wire in the hydrochloric acid solution is subject to cleaning, and visual inspection is required after soaking for 15 minute...

Embodiment 2

[0083] The production process of environmentally-friendly non-copper-plated solid welding wire includes an offline hydrochloric acid washing process of welding wire raw materials, a drawing process and a copper-free process; the copper-free process includes a phytic acid treatment step and a post-treatment step:

[0084] 2. Offline hydrochloric acid washing process of welding wire raw material (steel): including pickling, water rinsing and neutralization washing steps in sequence:

[0085] Pickling-water rinsing-neutralization washing.

[0086] During the pickling, a hydrochloric acid solution with a concentration of 5% by weight was used to clean the surface of the welding wire raw material, and the Fe in the solution after the pickling 2+ The concentration of the welding wire is controlled to be ≤200g / L; the time to soak the raw material of the welding wire in the hydrochloric acid solution is subject to cleaning, and visual inspection is required after soaking for 15 minutes.

[008...

Embodiment 3

[0117] The production process of environmentally-friendly non-copper-plated solid welding wire includes an offline hydrochloric acid washing process of welding wire raw materials, a drawing process and a copper-free process; the copper-free process includes a phytic acid treatment step and a post-treatment step:

[0118] 3. Offline hydrochloric acid washing process of welding wire raw material (steel): including pickling, water rinsing and neutralization washing steps in sequence:

[0119] Pickling-water rinsing-neutralization washing.

[0120] During the pickling, a hydrochloric acid solution with a concentration of 10% by weight is used to clean the surface of the welding wire raw material, and the Fe in the pickling solution 2+ The concentration of the welding wire is controlled to be ≤200g / L; the time to soak the raw material of the welding wire in the hydrochloric acid solution is subject to cleaning, and visual inspection is required after soaking for 15 minutes.

[0121] During ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com