Polyester spinning method of reducing screw melt extrusion machine

A polyester spinning and melt extrusion technology, applied in the field of polyester spinning, can solve the problem of affecting the quality of the raw silk, affecting the uniformity of the spinning nozzle, the quality of fiber forming, and the instability of melt advancement, etc. problems, to achieve the effect of facilitating the removal of water, pre-crystallization and softening uniformity, and saving factory space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

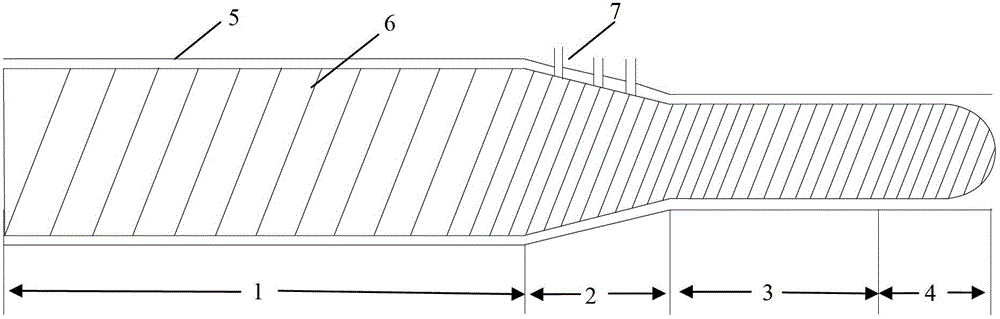

[0023] A polyester spinning method using a variable-diameter screw melt extruder is used to melt and extrude PET pellets with a melting point of 265°C and a moisture content of 112ppm, wherein the outer cone angle of the conical cylinder is 20 degrees , the pre-melting exhaust zone accounts for 15% of the entire screw, the pre-crystallization drying zone accounts for 40% of the total screw length, and the melting zone accounts for 10% of the total screw length; the temperature of the feed pre-crystallization drying is controlled at 120°C, and the The temperature of melting extraction is controlled at 260°C; the diameter ratio of the cylinder in the feed pre-crystallization drying zone to the cylinder in the melting zone is 3:1; the conical cylinder in the pre-melting exhaust zone is equipped with 16 exhaust ports , the diameter of the exhaust port is 12mm, and the exhaust port is connected to a vacuum device, and the moisture content of PET obtained at the mouth of the melt ext...

Embodiment 2

[0025] A polyester spinning method using a variable-diameter screw melt extruder is used to melt and extrude PBT pellets with a melting point of 260°C and a moisture content of 80ppm, wherein the outer cone angle of the conical cylinder is 10 degrees , the pre-melting exhaust zone accounts for 13% of the entire screw, the pre-crystallization drying zone accounts for 35% of the total screw length, and the melting zone accounts for 15% of the total screw length. The temperature of the feed pre-crystallization drying is controlled at 115°C. The temperature of melting extraction is controlled at 255±2°C; the diameter ratio of the cylinder in the feed pre-crystallization drying zone to the cylinder in the melting zone is 2:1; the conical cylinder in the pre-melting exhaust zone is equipped with 8 rows The air port and the exhaust port aperture are 6mm, and the moisture content of PBT obtained at the mouth of the melt extruder is 23ppm; the spinning assembly is installed at the end o...

Embodiment 3

[0027] A polyester spinning method using a variable-diameter screw melt extruder is used to melt and extrude PTT pellets with a melting point of 255°C and a moisture content of 76ppm, wherein the outer cone angle of the conical cylinder is 15 degrees , the pre-melting exhaust zone accounts for 10% of the entire screw, the pre-crystallization drying zone accounts for 30% of the total screw length, the melting zone accounts for 15% of the total screw length, and the temperature of the feed pre-crystallization drying is controlled at 110-120°C , the temperature of the pre-melting air extraction is controlled at 249±1°C; the diameter ratio of the cylinder in the feed pre-crystallization drying zone to the cylinder in the melting zone is 1.5:1; the conical cylinder in the pre-melting exhaust zone is installed with 4 One exhaust port, the exhaust port aperture 8mm, the exhaust port is connected with a vacuum device, and the water content of the PTT obtained at the mouth of the meltin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com