Thin-wall double-layer insulated cable with high voltage resistance

A double-layer insulation, high-voltage technology, applied in the direction of insulated cables, insulated conductors, non-insulated conductors, etc., can solve the problems of rough interface, fluctuation in outer diameter, difficult bonding, etc., to reduce weight, save wiring space, and excellent resistance. Chemical Corrosive Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

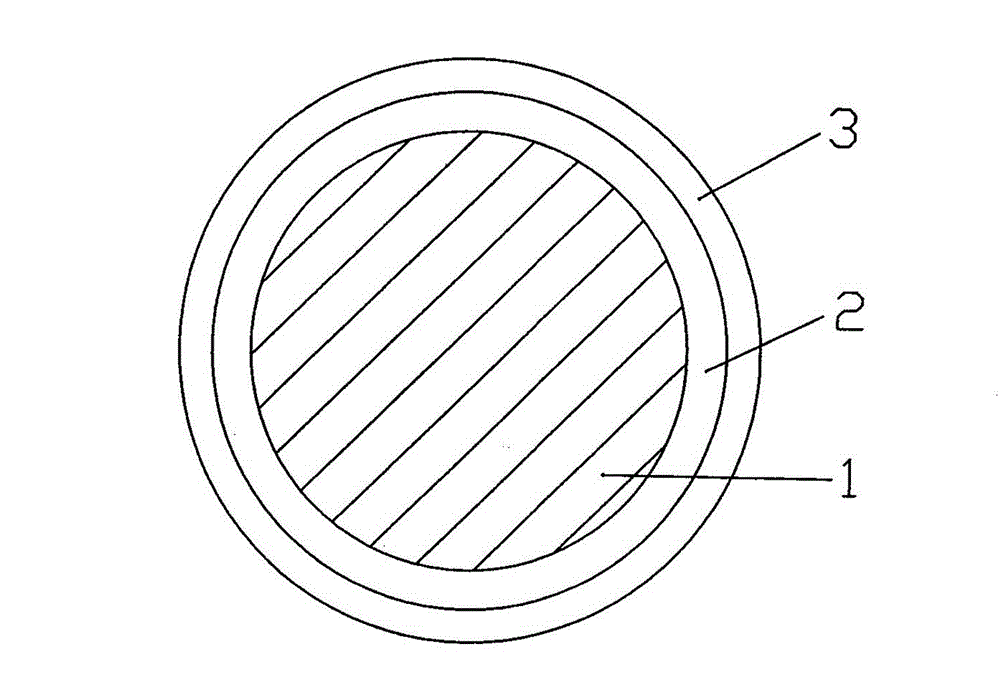

[0015] please see figure 1 , the given conductor 1 is composed of a plurality of tinned copper wires with a diameter of 0.1-0.3㎜ twisted, an inner insulating layer 2 made of cross-linked polyolefin is combined outside the conductor 1, and an inner insulating layer 2 is combined outside the inner insulating layer 2. The outer insulating layer 3 is made of polyvinylidene fluoride. In this embodiment, the thicknesses of the inner and outer insulating layers 2 and 3 are the same, but it is also possible to make the thickness of the inner insulating layer 2 thicker than the thickness of the outer insulating layer 3, and vice versa. The thicknesses of the insulating layers 2 and 3 are both 0.8 mm.

Embodiment 2

[0017] Only the thickness of the inner insulating layer 2 is changed to 0.45 mm, and the thickness of the outer insulating layer 3 is changed to 0.05 mm, and the rest are the same as the description of embodiment 1.

Embodiment 3

[0019] Only the thickness of the inner insulating layer 2 is changed to 0.08 mm, and the thickness of the outer insulating layer 3 is changed to 0.10 mm, and the rest are the same as the description of embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com