Method for enhancing capsule wall toughness of self-repairing microcapsules, and self-repairing microcapsules prepared by the same

A technology for self-repairing microcapsules and capsule walls, which is applied in the direction of microcapsule preparation and microsphere preparation. Enhanced or weakened toughness, enhanced toughness, and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

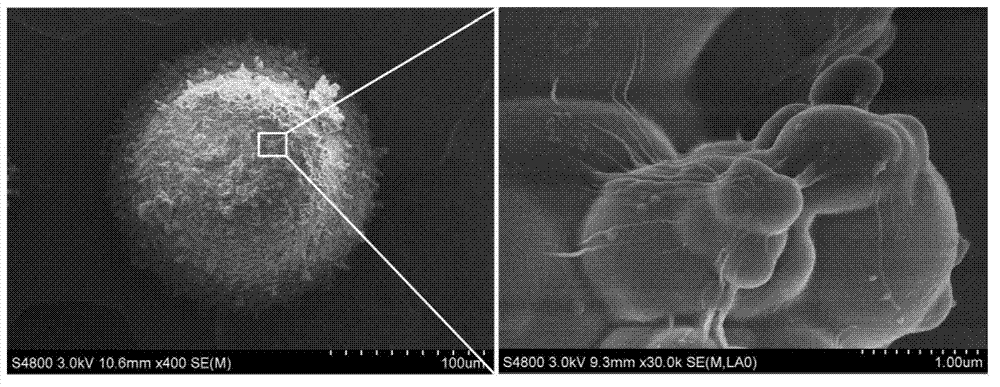

Embodiment 1

[0075] Take 1g of single-walled carbon nanotubes and place them in the plasma discharge chamber, pass the functional reaction gas n-butanol into the plasma discharge chamber at a rate of 100ml / min, wait for the gas to flow in evenly, and turn on the discharge switch for plasma discharge , the plasma discharge surface modification process continued for 60 minutes, and then the power of the discharge device was turned off to obtain a plasma-modified carbon material, and 5 g of urea and 5 g of 37% formaldehyde solution were added to a four-neck flask and mixed. Use triethanolamine to adjust the pH to the range of 7.5~11.8, and slowly raise the temperature to 75°C for 3 hours to generate a viscous and transparent water-soluble urea-formaldehyde prepolymer solution, and add the plasma-modified carbon material to the prepolymer solution In, stir to disperse evenly. Take 8g of 4,4'-diphenylmethane diisocyanate, 1.4g of capsule core diluent 1-butyl glycidyl ether, and 2g of cosolvent ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com