Preparation method of high temperature stable monolithic catalyst for purifying tail gas of automobile

A monolithic catalyst and automobile exhaust technology, applied in chemical instruments and methods, separation methods, dispersed particle separation, etc., can solve the problem of aggravating the growth, sintering and aggregation of noble metal active components and cerium oxide grains, and the specific surface area of catalysts decrease in catalyst activity, etc., to achieve the effect of improving the coating process, good fluidity, and high temperature resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

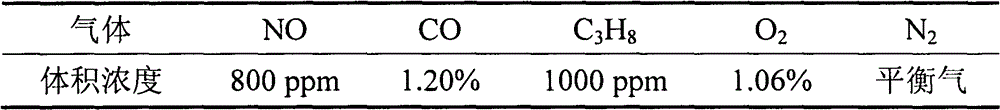

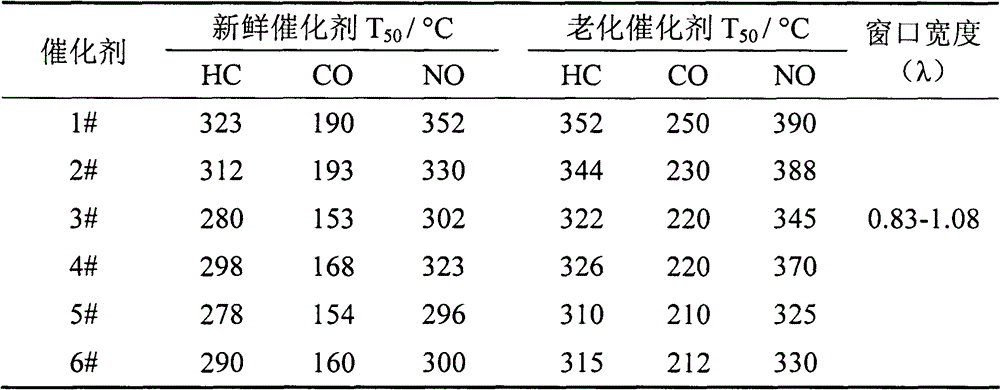

Embodiment 1

[0016] Pd(NO 3 ) 2 Aqueous solution (Pd accounts for 0.8% of dry coating mass), cerium nitrate, nickel nitrate and manganese nitrate (mixed oxide accounts for 5% of dry coating mass) joins 120g deionized water, forms solution (I) after stirring for 10 minutes ; add 50g La-Al 2 o 3 , stirred for 6h; under stirring, add 5g of pseudoboehmite and 10g of cerium-zirconium solid solution, add 5mL of concentrated nitric acid, adjust the pH to 3-4, and continue stirring for 1 hour; coat the slurry on the cordierite honeycomb ceramic carrier under vacuum (The size is 15mm×30mm, the volume is 5.3mL); dry at room temperature for 12 hours, dry at 120°C for 12 hours, and roast in air at 500°C for 3 hours to obtain fresh catalyst 1#; obtain aged catalyst after roasting at 1000°C for 4 hours , their three-way catalytic activity (T 50 , reaction temperature when conversion rate is 50%) see Table 2.

Embodiment 2

[0018] In the process of [Example 1] preparing the slurry, add 1g (a mixture of Polyethylene Glycol-200 and Tween-80) surfactant in solution (I), and other conditions are the same as [Example 1]. Get fresh catalyst 2#.

Embodiment 3

[0020] [Example 1] In the process of preparing the slurry, add 3g (a mixture of polyethylene glycol-200 and Tween-80) surfactant in the solution (I), and other conditions are the same as [Example 1]. Get fresh catalyst 3#.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com