Self-supporting noble metal nanosheet with equal thickness of monatomic layer and preparation method of nanosheet

A single atomic layer, precious metal technology, applied in the field of inorganic functional materials, can solve the problems of unreported synthesis and harsh preparation methods, and achieve the effect of simple process, low cost and good repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Step A: Add 6 mg of RhCl 3 ·3H 2 O and 100 mg of polyvinylpyrrolidone with a molecular weight of 20,000-25,000 were added to 5 mL of a mixed solution of methanol and benzaldehyde at a volume ratio of 1:1, and stirred at 30° C. for 60 min;

[0022] Step B: Put the mixed solution prepared in step A into a polytetrafluoroethylene hydrothermal reaction kettle, seal it and keep it at a constant temperature of 150°C for 10 hours, then add 40mL of acetone and leave it for 8 hours, wash it with ethanol for three times, and finally the product is evenly dispersed in ethanol , to obtain self-supporting, monoatomically thick rhodium nanosheets.

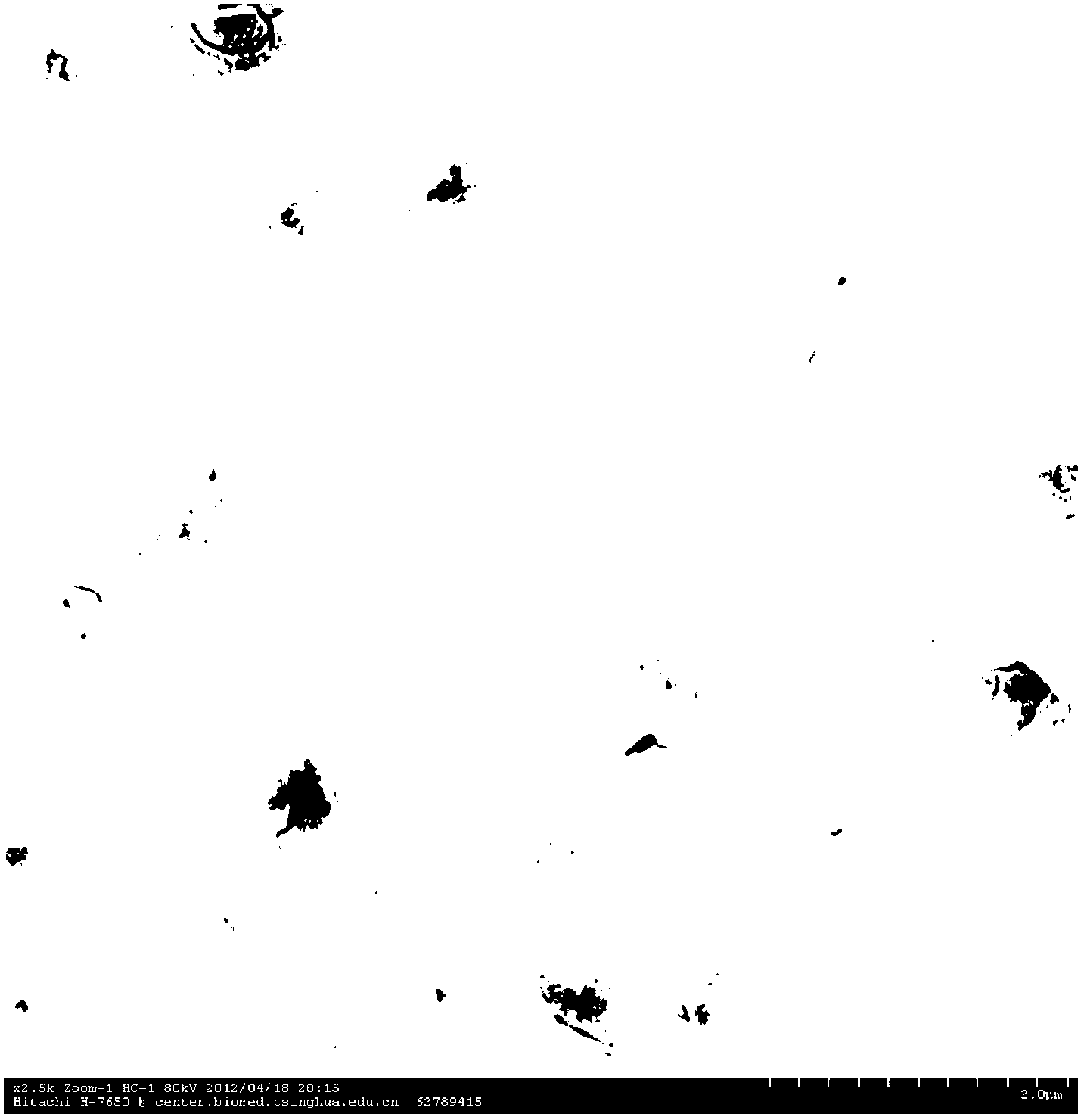

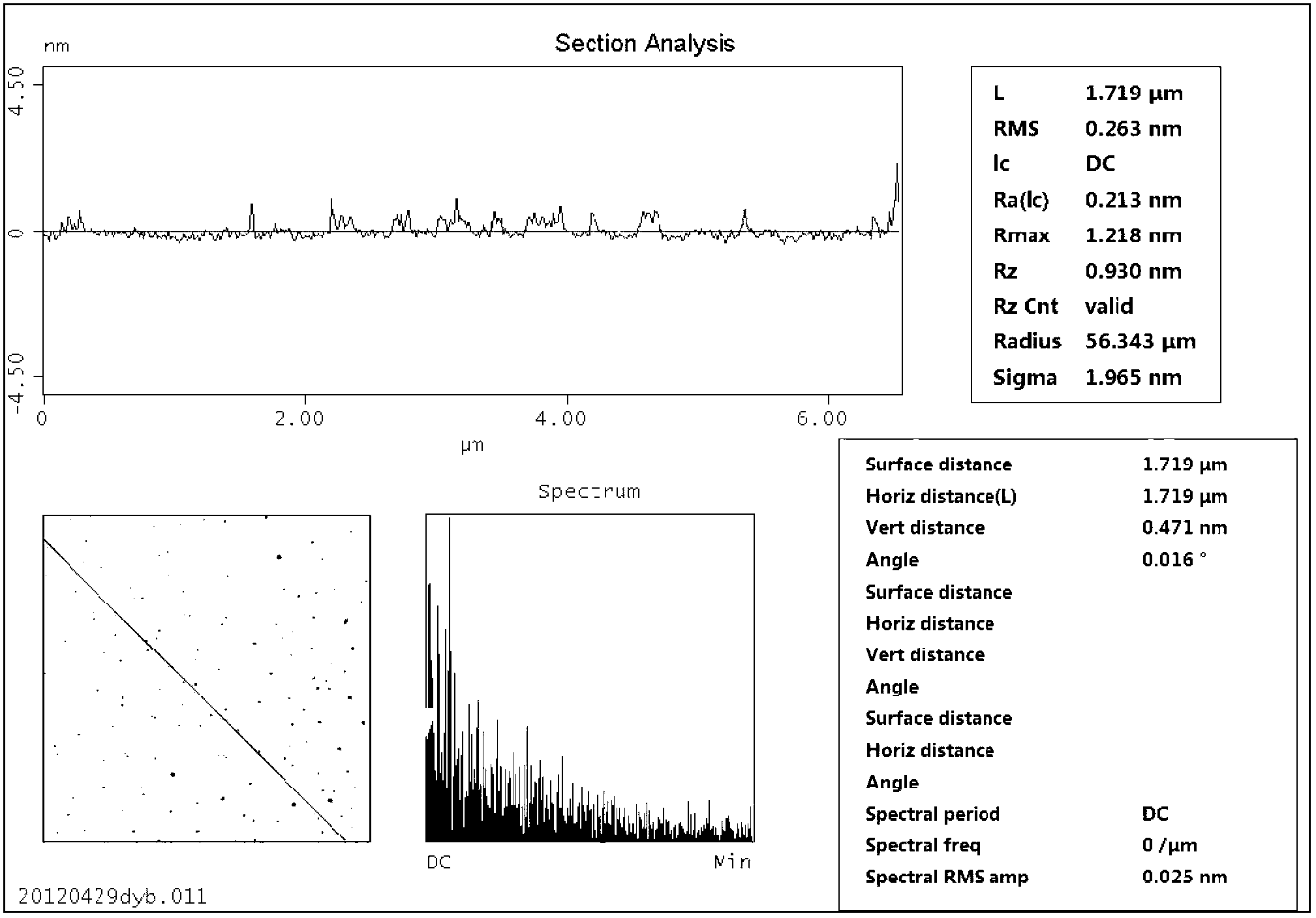

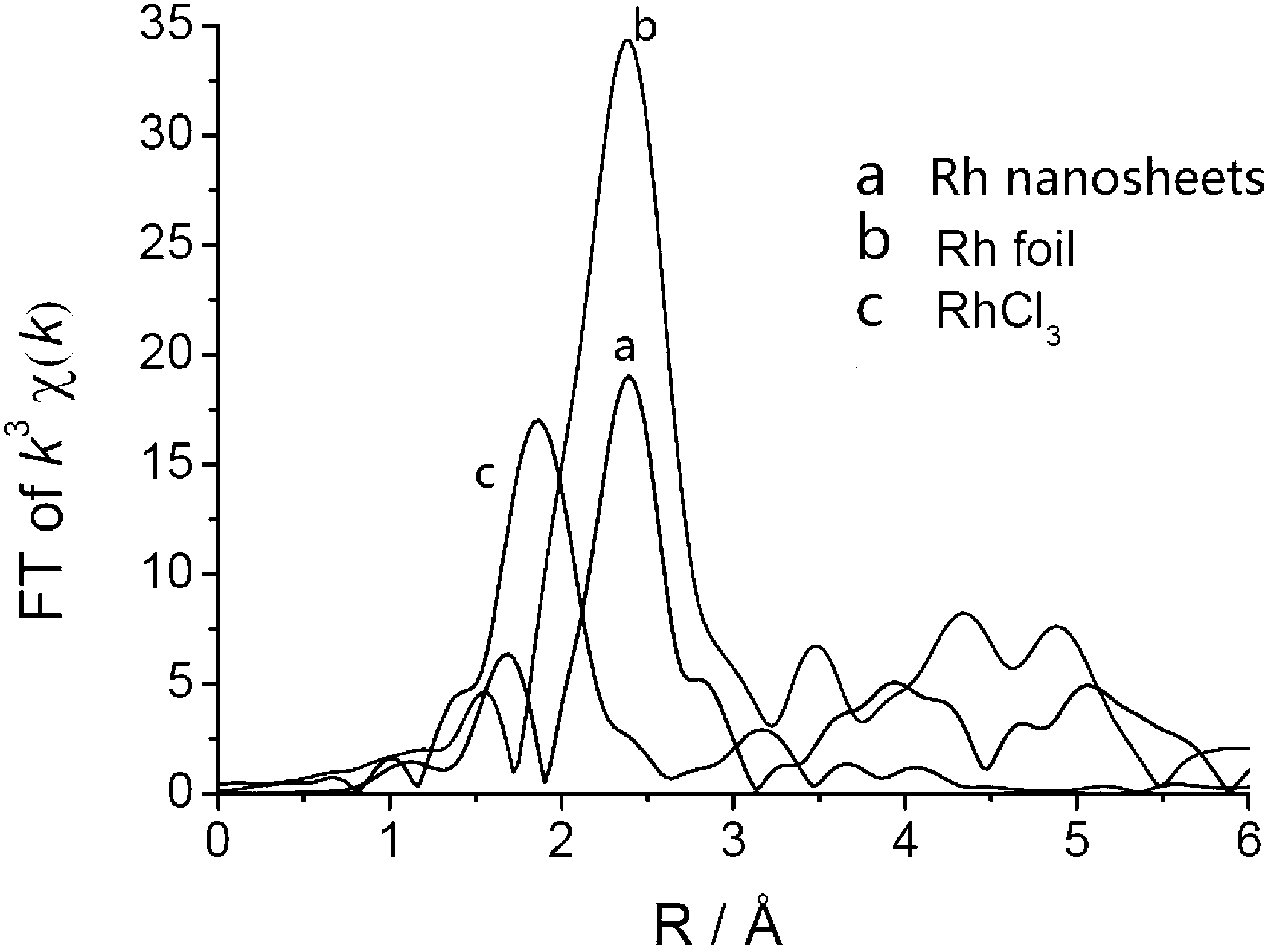

[0023] The resulting rhodium nanosheets were subjected to TEM (see figure 1 ), EDX, AFM (see figure 2 ), XAFS (see image 3 ) and other representations. Depend on figure 1 It is confirmed that the synthesized product is a monodisperse nanosheet with a size of (300nm×300nm)-(400nm×400nm)nm. The nanosheets were confirmed to be rhodi...

Embodiment 2

[0026] Step A: Add 6 mg of Pd(acac) 2 and 100 mg of polyvinylpyrrolidone with a molecular weight of 40,000-45,000 were added to 5 mL of a mixed solution of phenethyl alcohol and benzaldehyde at a volume ratio of 5:1, and stirred at 40°C for 60 min;

[0027] Step B: Put the mixed solution prepared in step A into a polytetrafluoroethylene hydrothermal reaction kettle, seal it and keep it at a constant temperature of 180°C for 10 hours, then add 40mL of acetone and leave it for 8 hours, wash it with ethanol for three times, and finally the product is evenly dispersed in dimethyl Self-supporting, monoatomically thick palladium nanosheets were obtained in sulfoxide.

[0028] The self-supporting, monoatomically thick palladium nanosheets prepared above have a size of (300nm×300nm)-(400nm×400nm), a thickness of 0.274nm, and are monodispersed palladium nanosheets with a thickness of a palladium atom; the palladium nanosheets All the atoms of the sheet are surface atoms and are in a s...

Embodiment 3

[0030] Step A: Add 6 mg of NaAuCl 4 2H 2 O and 120 mg of polyvinylpyrrolidone with a molecular weight of 50,000-55,000 were added to 5 mL of a mixed solution of ethanol and isobutyraldehyde at a volume ratio of 1:5, and stirred at 20° C. for 60 min;

[0031] Step B: Put the mixed solution prepared in step A into a polytetrafluoroethylene hydrothermal reaction kettle, seal it and keep it at a constant temperature of 120°C for 10 hours, then add 40mL of acetone and leave it for 8 hours, wash it with ethanol for three times, and finally the product is evenly dispersed in water. Self-supporting, monoatomically thick gold nanosheets were obtained.

[0032] The self-supporting, monoatomically thick gold nanosheets prepared above have a size of (300nm×300nm)-(400nm×400nm), a thickness of 0.288nm, and are monodisperse gold nanosheets with a gold atom thickness; the gold nanosheets All the atoms of the sheet are surface atoms, which are stable in a six-coordination state; the gold na...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com