Method for separating potassium chloride and potassium fluoride

A separation method, potassium chloride technology, applied in the direction of purification of boron halide compounds, alkali metal halides, etc., can solve the problems of secondary waste water or waste gas pollution, high cost, large cost and environmental protection problems, and achieve low cost and reduced The effect of simple production cost and process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

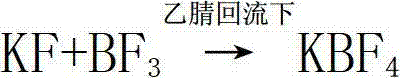

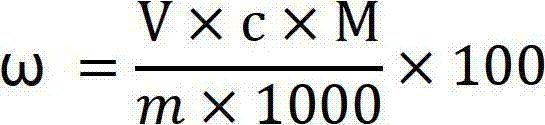

[0024] Add 75.0 g of fluorination reaction by-product KCl-KF mixed salt (9.2% potassium fluoride mass fraction) dried at 300°C for 1 hour to 200.2 g of 5% boron trifluoride acetonitrile solution, and reflux for 5 hours under stirring. Filter to obtain 65.8g of potassium chloride, heat and evaporate the acetonitrile solution containing potassium tetrafluoroborate to recover acetonitrile and excess boron trifluoride acetonitrile, cool and crystallize, filter to obtain potassium tetrafluoroborate, and dry to obtain 14.6g of potassium tetrafluoroborate , through the solid moisture detection instrument (Mitsubishi Chemical CA-200 / VA200), the moisture is 785ppm, and the yield is 97.4%.

Embodiment 2

[0026] Add 100.0 g of fluorination reaction by-product KCl-KF mixed salt (12% potassium fluoride mass fraction) dried at 400°C for 3 hours to 85.1 g of 20% boron trifluoride acetonitrile solution, and reflux for 24 hours under stirring. 86g of potassium chloride was obtained by filtration, and the acetonitrile solution containing potassium tetrafluoroborate was directly spray-dried to obtain 25.3g of potassium tetrafluoroborate, which passed the solid moisture detection instrument (Mitsubishi Chemical CA-200 / VA200) with a moisture content of 687ppm and a yield of 97.0%.

Embodiment 3

[0028] Add 100.0g of fluorination reaction by-product KCl-KF mixed salt (20% potassium fluoride mass fraction) dried at 500°C for 5 hours to 260.5g of 10% boron trifluoride acetonitrile solution, and reflux for 24 hours under stirring. 78.2g of potassium chloride was obtained by filtration, and the clear liquid of the acetonitrile solution containing potassium tetrafluoroborate was directly spray-dried to obtain 42.3g of potassium tetrafluoroborate, and the moisture content was 693ppm through the solid moisture detection instrument (Mitsubishi Chemical CA-200 / VA200). The rate is 97.3%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com