Large-area contact type machining device for fused quartz by plasma discharge machining

A plasma and electrical discharge machining technology, used in manufacturing tools, glass manufacturing equipment, glass molding, etc., can solve the problems of low reactive ion activity, short processing time, high electrode temperature, and achieve high removal efficiency, good processing effect, The effect of reducing the electrode temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

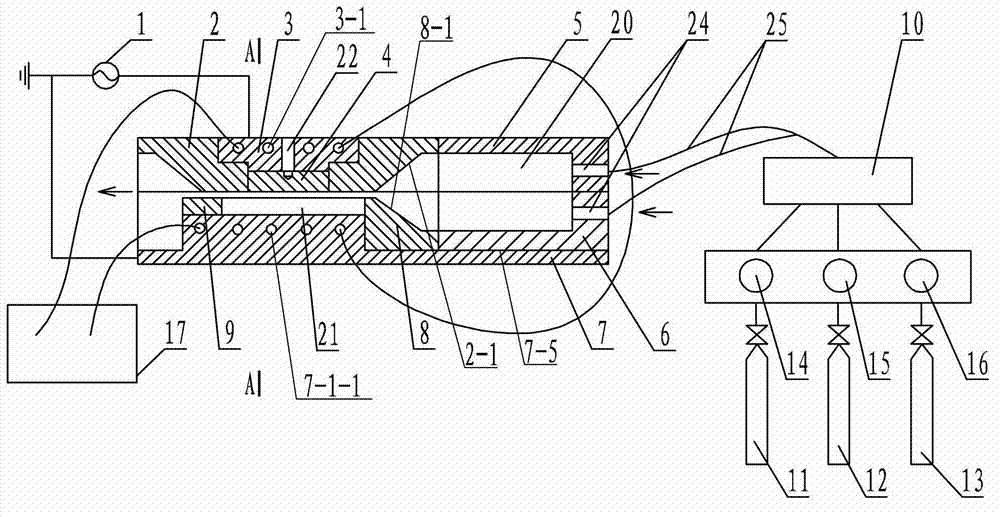

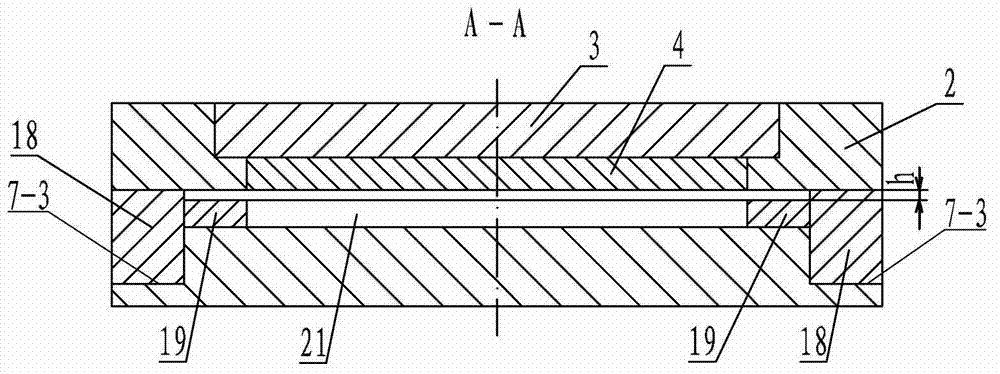

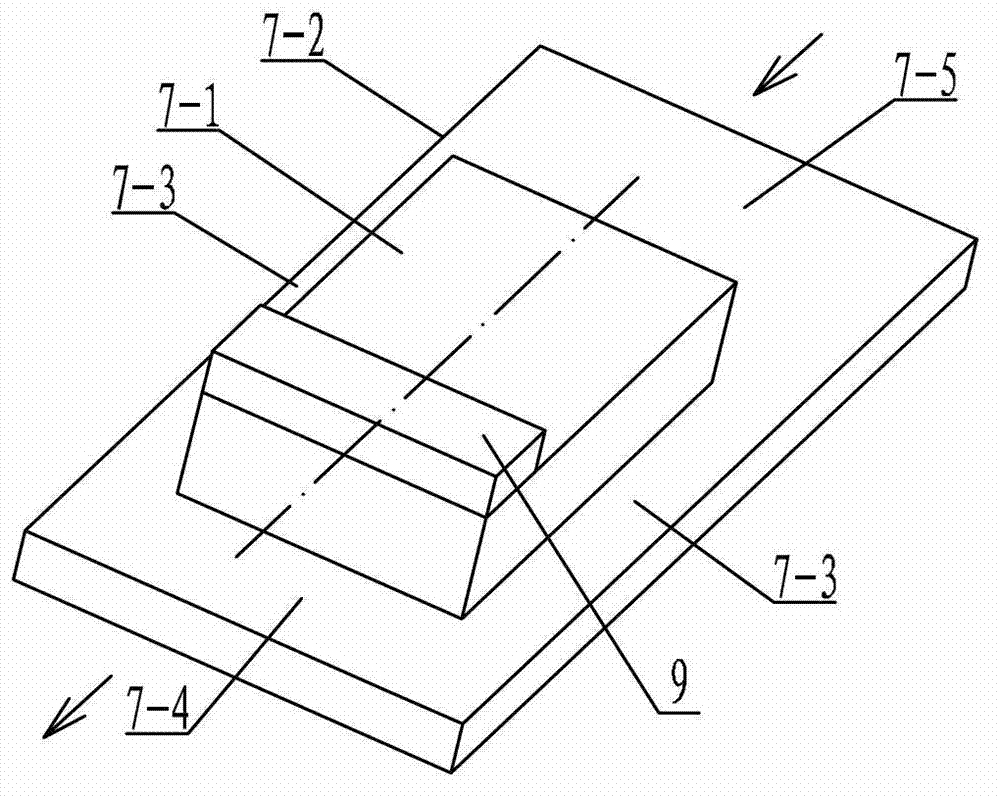

[0009] Specific implementation mode 1. Combination Figure 1 ~ Figure 3 Describe this embodiment, the large-area contact plasma discharge machining fused silica processing device of this embodiment includes a radio frequency power supply 1, a high electrode 3, a forming electrode 4, an upper guide body 5, a lower guide body 6, a ground electrode 7, a wind guide Plate 8, end workpiece splint 9, gas mixing box 10, helium gas cylinder 11, carbon tetrafluoride gas cylinder 12, oxygen cylinder 13, helium gas flowmeter 14, carbon tetrafluoride flowmeter 15, oxygen flowmeter 16. Water pump 17, pin 22, two upper case covers 2, two side plates 18 and two air ducts 25, the ground electrode 7 is composed of an upper end plate 7-1 and a base plate 7-2, and the upper end plate 7-1 is The longitudinal centerline of the base plate 7-2 is arranged on the base plate 7-2, and the upper end plate 7-1 is integrated with the base plate 7-2, and the upper end surface of the base plate 7-2 is positi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com