High wear-resistant low-smoke halogen-free irradiation crosslinking sheathing material and preparation method thereof

A sheath material, high wear resistance technology, used in plastic/resin/wax insulators, organic insulators, etc., can solve the problems of poor wear resistance, poor appearance of wires and cables, and achieve excellent flame retardant performance, good resistance The effect of low temperature performance and excellent wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

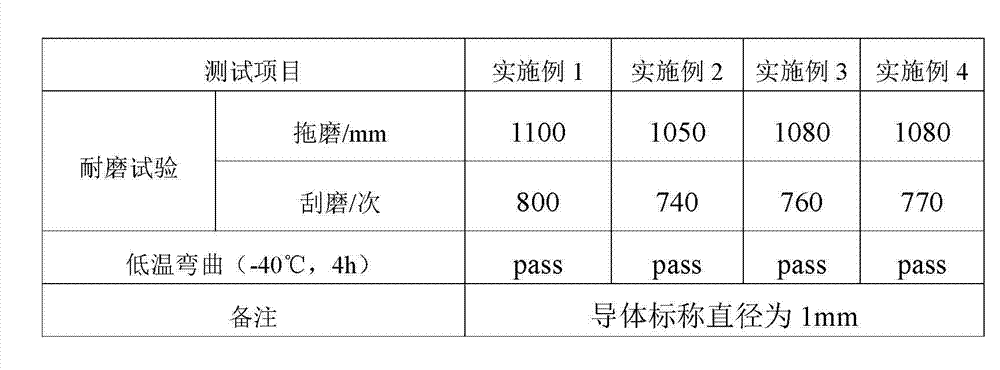

Examples

Embodiment 1

[0032] A highly wear-resistant low-smoke halogen-free radiation cross-linked sheath material is composed of the following components:

[0033] EVA: 35kg, Modified UHMWPE: 3kg, Ethylene-Methacrylic Acid Sodium Salt Copolymer: 3kg, Aluminum Hydroxide: 50kg, Carbon Black: 3kg, Compatibilizer: 4kg, Antioxidant Oxygen: 0.3kg, Lubricant: 0.5kg, Silicone Powder: 1.2kg

[0034] In the ethylene-vinyl acetate copolymer, the mass percentage of vinyl acetate is 28%. The modified ultra-high molecular weight polyethylene has a molecular weight of 3 million and a melt index of 5. The aluminum hydroxide is surface-modified aluminum hydroxide of a silane coupling agent, and the mesh number is 6000 meshes. The carbon black is thermal cracking carbon black, and the mass percentage of carbon is ≥99%. The compatibilizer is maleic anhydride grafted EVA, and the graft ratio is 1.5%. The antioxidant is tetrakis [beta-(3,5-di-tert-butyl-4-hydroxyphenyl) propionate] pentaerythritol ester. The lubr...

Embodiment 2

[0039] A highly wear-resistant low-smoke halogen-free radiation cross-linked sheath material is composed of the following components:

[0040] EVA: 30 kg, modified ultra-high molecular weight polyethylene: 5 kg, ethylene-methacrylic acid sodium salt copolymer: 5 kg, aluminum hydroxide: 51 kg, carbon black: 3 kg, compatibilizer: 4 kg, anti- Oxygen: 0.3kg, Lubricant: 0.5kg, Silicone Powder: 1.2kg

[0041] In the ethylene-vinyl acetate copolymer, the mass percentage of vinyl acetate is 26%. The modified ultra-high molecular weight polyethylene has a molecular weight of 3 million and a melt index of 5. The aluminum hydroxide is surface-modified aluminum hydroxide of a silane coupling agent, and the mesh number is 5000 meshes. The carbon black is thermal cracking carbon black, and the mass percentage of carbon is ≥99%. The compatibilizer is maleic anhydride grafted ethylene octene copolymer, and the graft ratio is 1.5%. The antioxidant is tetrakis [beta-(3,5-di-tert-butyl-4-hyd...

Embodiment 3

[0044] A highly wear-resistant low-smoke halogen-free radiation cross-linked sheath material is composed of the following components:

[0045] EVA: 32 kg, modified ultra-high molecular weight polyethylene: 4 kg, ethylene-methacrylic acid sodium salt copolymer: 4 kg, aluminum hydroxide: 52 kg, carbon black: 3 kg, compatibilizer: 3 kg, anti- Oxygen: 0.3kg, Lubricant: 0.5kg, Silicone Powder: 1.2kg

[0046] In the ethylene-vinyl acetate copolymer, the mass percentage of vinyl acetate is 28%. The modified ultra-high molecular weight polyethylene has a molecular weight of 3 million and a melt index of 5. The aluminum hydroxide is surface-modified aluminum hydroxide of a silane coupling agent, and the mesh number is 6000 meshes. The carbon black is thermal cracking carbon black, and the mass percentage of carbon is ≥99%. The compatibilizer is maleic anhydride grafted EVA, and the graft ratio is 1.5%. The antioxidant is tetrakis [beta-(3,5-di-tert-butyl-4-hydroxyphenyl) propionate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Mesh | aaaaa | aaaaa |

| Mesh | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com