Phosphorus-containing Schiff base derivative intumescent fire retardant and preparation method thereof

A technology of intumescent flame retardant and Schiff base, which is applied in the field of phosphorus-containing Schiff base derivative intumescent flame retardant and its preparation, can solve the problem of material mechanical properties and processing performance damage, thermal decomposition temperature limit application, resistance problems such as the decline in fuel efficiency, and achieve the effects of good application prospects, easy control, and high carbon formation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

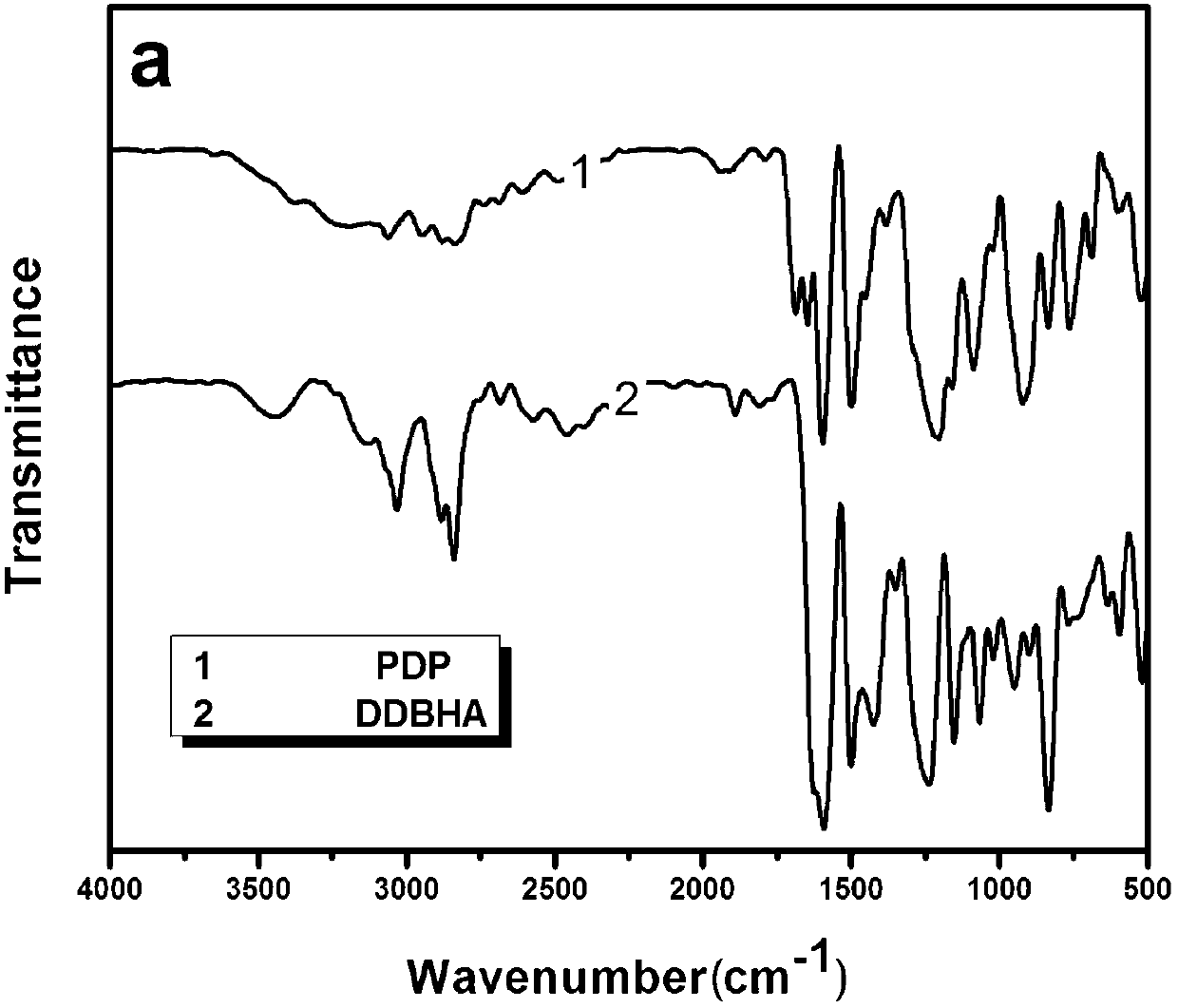

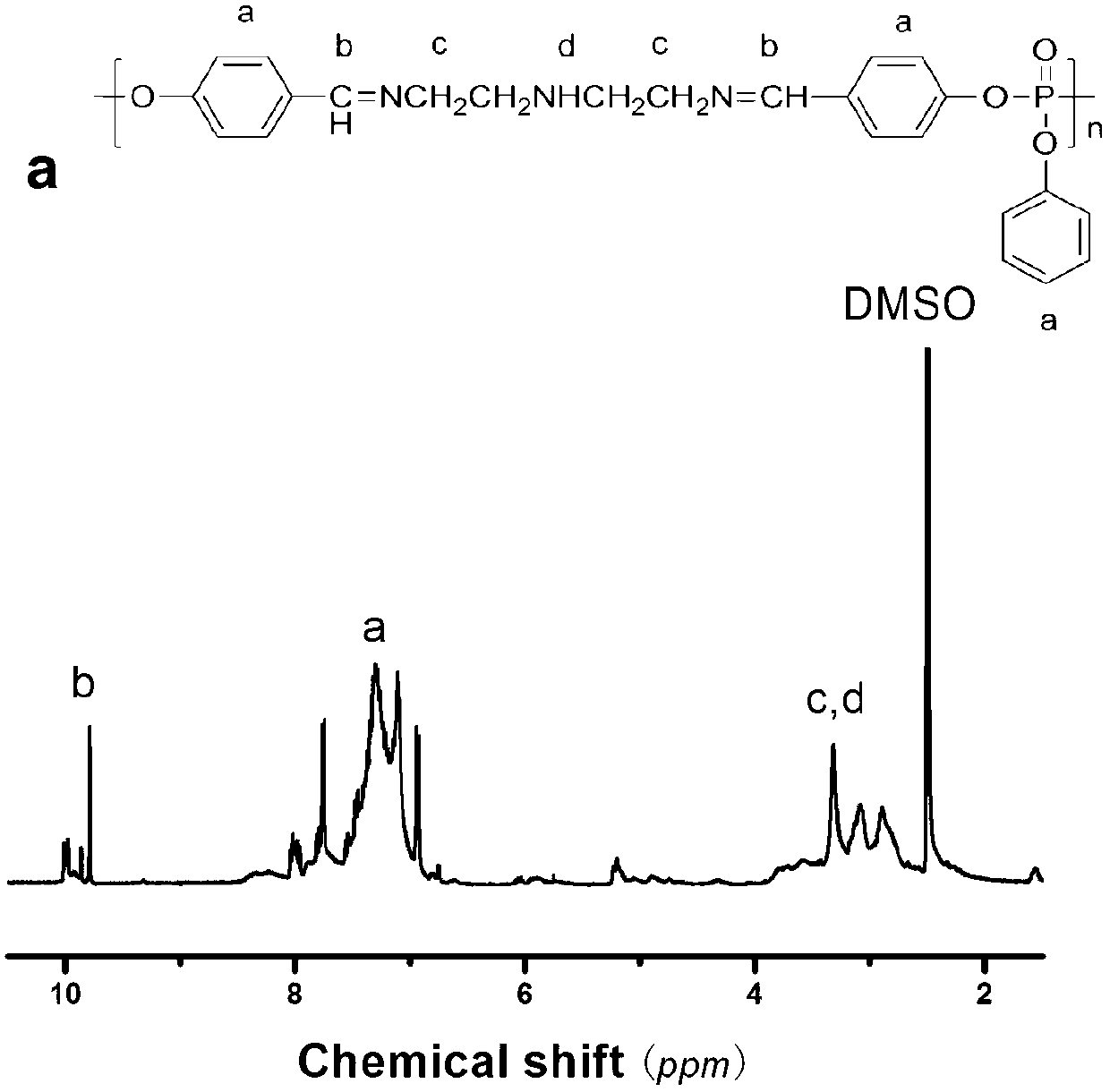

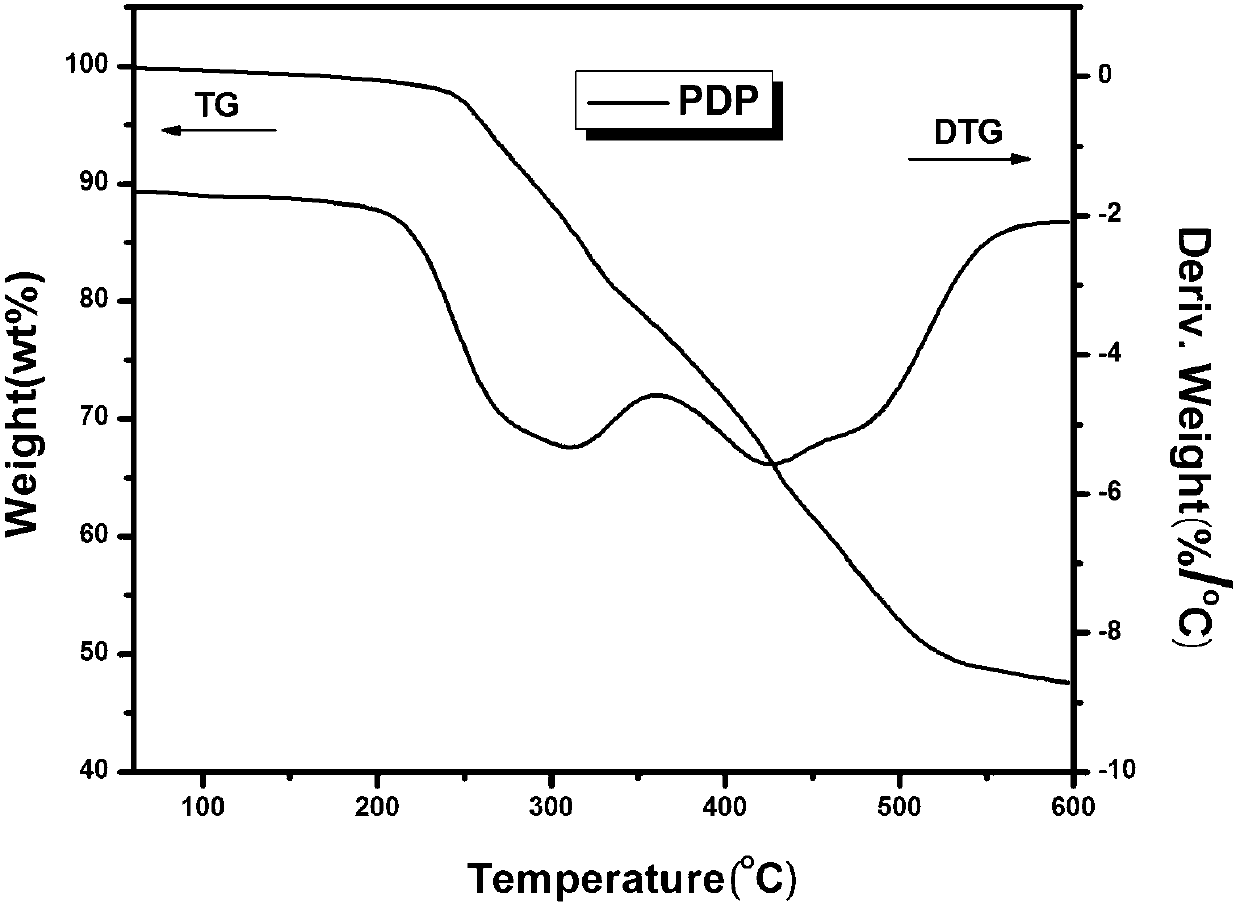

[0045] Add 20mmol of p-hydroxybenzaldehyde and 100ml of absolute ethanol in a 250ml flask, heat to 50°C under stirring, then dissolve 10mmol of diethylenetriamine in 100ml of absolute ethanol, slowly drop into the flask, and continue the reaction for 2h. After cooling to room temperature, a large amount of yellow solids precipitated, filtered with suction, washed three times with absolute ethanol and deionized water, precipitated with deionized water, and dried in a vacuum oven to obtain the product DDBHA with general structural formula (II) (infrared spectrum See figure 1 ). Add 5mmol DDBHA, 10mmol NaOH, 0.05mmol of phase transfer catalyst tetrabutylammonium bromide and 25ml of deionized water into the three-necked flask, mechanically stir at 25°C to completely dissolve DDBHA, then quickly add benzene dichlorinated phosphate 25ml of the dichloromethane solution of the ester was stirred quickly, and after 1 hour of reaction, the product was suction filtered, rinsed with a lar...

Embodiment 2

[0051] Add 20mmol of p-hydroxybenzaldehyde and 100ml of absolute ethanol in a 250ml flask, heat it to 50°C under stirring, then slowly add 10mmol of ethylenediamine and 100ml of absolute ethanol dropwise into the flask, continue the reaction for 1h, and cool to room temperature A large amount of yellow solids were precipitated, filtered by suction, washed three times with absolute ethanol and deionized water respectively, precipitated with deionized water, and dried in a vacuum oven to obtain the product EDBHA with the general structure formula (II) (infrared spectrum see image 3 ). Add 5mmol EDBHA, 10mmol NaOH, 0.05mmol of phase transfer catalyst tetrabutylammonium chloride and 25ml of deionized water into the three-necked flask, mechanically stir at 25°C to completely dissolve the EDBHA, then quickly add benzene dichlorinated phosphate 25ml of the dichloromethane solution of the ester was stirred quickly, and after 1 hour of reaction, the product was suction-filtered, rinse...

Embodiment 3

[0057] Add 20mmol of p-hydroxybenzaldehyde and 100ml of absolute ethanol in a 250ml flask, heat to 50°C under stirring, then slowly add 10mmol of p-phenylenediamine and 100ml of absolute ethanol dropwise into the flask, continue the reaction for 3h, and cool to A large number of yellow solids precipitated at room temperature, filtered by suction, washed three times with absolute ethanol and deionized water, precipitated with deionized water, and dried in a vacuum oven to obtain the product PDBHA with the general structural formula (II) (infrared spectrum see Figure 5 ). Add 5mmol PDBHA, 10mmol NaOH, 0.05mmol of phase transfer catalyst tetrabutylammonium chloride and 25ml of deionized water into the three-necked flask, mechanically stir at 25°C to dissolve all the PDBHA, then quickly add benzene dichlorinated phosphate 25ml of the dichloromethane solution of the ester, stirred rapidly, after reacting for 1h, the product was suction filtered, rinsed with a large amount of deion...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com