Electromagnetic-wave absorption-material having periodic structure, and preparation method thereof

A technology of electromagnetic wave absorption and periodic structure, applied in chemical instruments and methods, other chemical processes, etc., can solve the problems of limited wave absorption bandwidth, large bulk density, narrow absorption bandwidth, etc., and achieve increased wave absorption bandwidth and low bulk density. , the effect of low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] a kind of like Figure 4 ~ Figure 6 The shown electromagnetic wave-absorbing material with a periodic structure of the present invention includes a magnetic wave-absorbing block 1 and a dielectric material grid 2, the mesh on the dielectric material grid 2 is a through hole, and the magnetic wave-absorbing block 1 is in accordance with a certain Periodically embedded in the through holes of the dielectric material grid 2. In this embodiment, embedding according to a certain period specifically refers to arranging embedding in a matrix to form a rectangular array of magnetic wave-absorbing blocks.

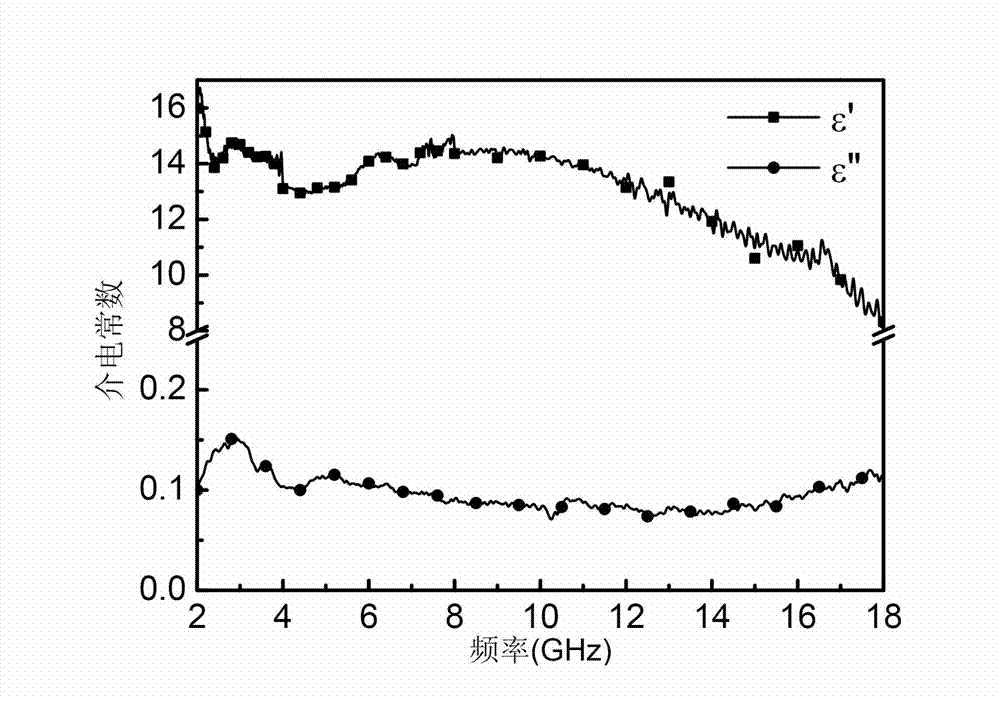

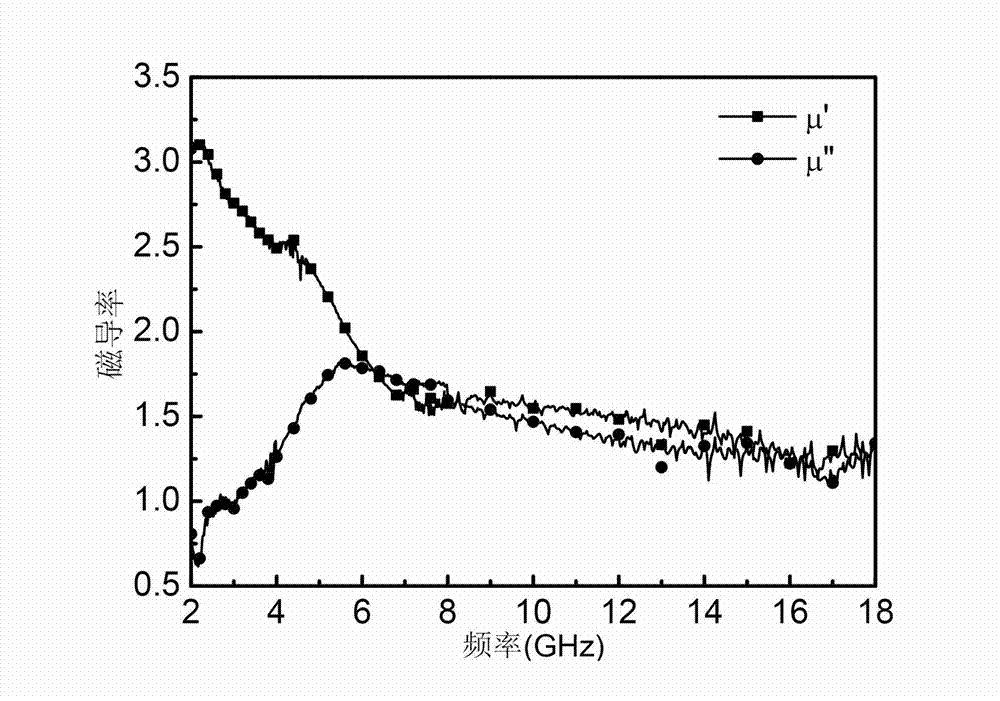

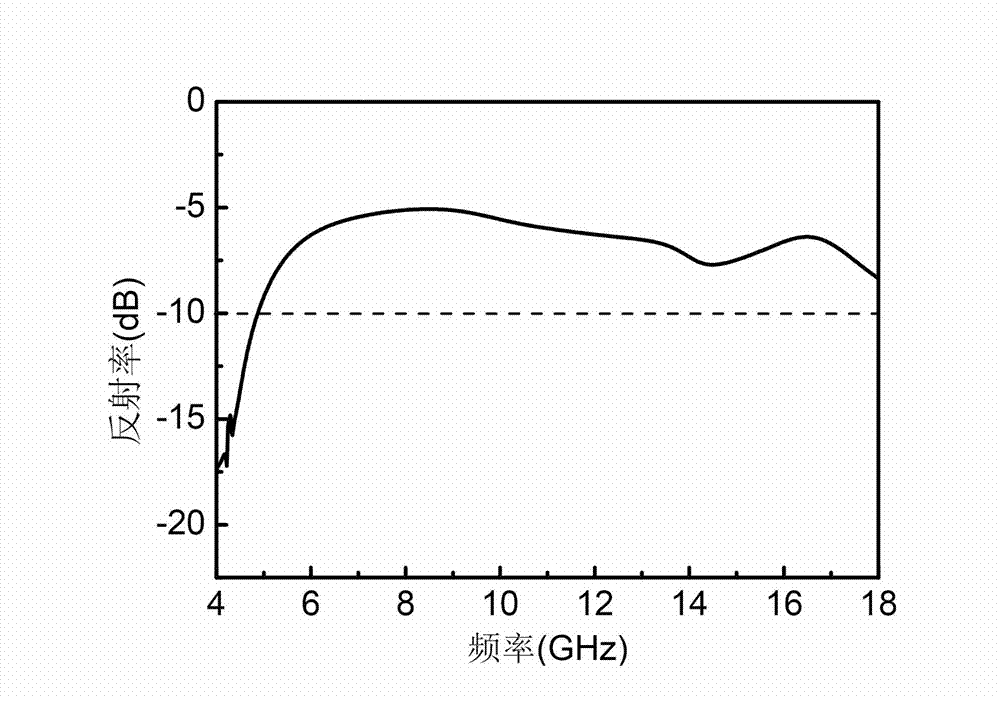

[0030] In this embodiment, the magnetic wave-absorbing block 1 is a square with a side length of 10 mm, and the distance between two adjacent magnetic wave-absorbing blocks 1 is 2.5 mm. The dielectric material grid 2 is made of doped polyimide foam material, its relative permittivity is about 2, and its dielectric loss is negligible. The thickness of the whole electromagnet...

Embodiment 2

[0037] a kind of like Figure 4 ~ Figure 5 The shown electromagnetic wave-absorbing material with a periodic structure of the present invention includes a magnetic wave-absorbing block 1 and a dielectric material grid 2, the mesh on the dielectric material grid 2 is a through hole, and the magnetic wave-absorbing block 1 is in accordance with a certain Periodically embedded in the through holes of the dielectric material grid 2. In this embodiment, embedding according to a certain period specifically refers to arranging embedding in a matrix to form a rectangular array of magnetic wave-absorbing blocks.

[0038] In this embodiment, the magnetic wave-absorbing block 1 is a square with a side length of 8 mm, and the distance between two adjacent magnetic wave-absorbing blocks 1 is 4.5 mm. The dielectric material grid 2 is made of doped polyimide foam material, its relative permittivity is about 2, and its dielectric loss is negligible. The thickness of the whole electromagneti...

Embodiment 3

[0042] a kind of like Figure 4 ~ Figure 5 The shown electromagnetic wave-absorbing material with a periodic structure of the present invention includes a magnetic wave-absorbing block 1 and a dielectric material grid 2, the mesh on the dielectric material grid 2 is a through hole, and the magnetic wave-absorbing block 1 is in accordance with a certain Periodically embedded in the through holes of the dielectric material grid 2. In this embodiment, embedding according to a certain period specifically refers to arranging embedding in a matrix to form a rectangular array of magnetic wave-absorbing blocks.

[0043] In this embodiment, the magnetic wave-absorbing block 1 is a square with a side length of 11 mm, and the distance between two adjacent magnetic wave-absorbing blocks 1 is 1.5 mm. The dielectric material grid 2 is made of doped polyimide foam material, its relative permittivity is about 2, and its dielectric loss is negligible. The thickness of the whole electromagnet...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com