Method for producing liquefied natural gas

A technology of liquefied natural gas and natural gas, applied in the directions of liquefaction, refrigeration and liquefaction, gas fuel, etc., can solve environmental problems and other problems, and achieve the effects of reducing energy consumption, strong industrial reliability, and good economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Embodiment 1, utilize semi-coke tail gas to produce liquefied natural gas

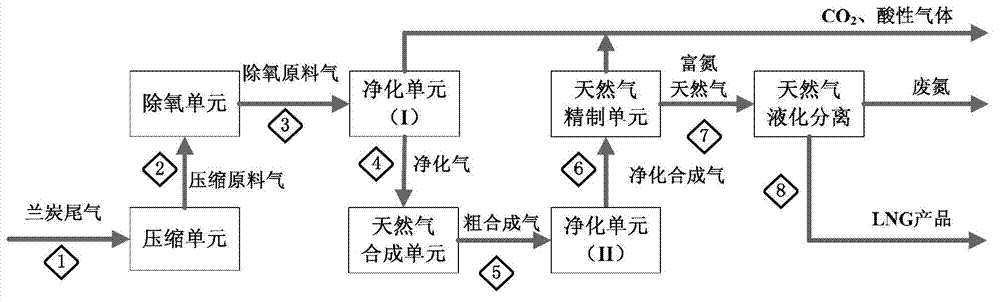

[0032] The schematic flow chart of the production of liquefied natural gas in this embodiment is as follows figure 1 shown.

[0033] The raw material gas composition of semi-coke tail gas is shown in Table 1:

[0034] Table 1 Average composition of semi-coke tail gas (vol%)

[0035]

[0036] Among them: low calorific value: 8187kJ / Nm 3 (1987kcal / Nm 3 ); Temperature: 40°C; Pressure: 0.03MPa(G).

[0037] The process is as follows:

[0038] (1) Deoxygenation unit

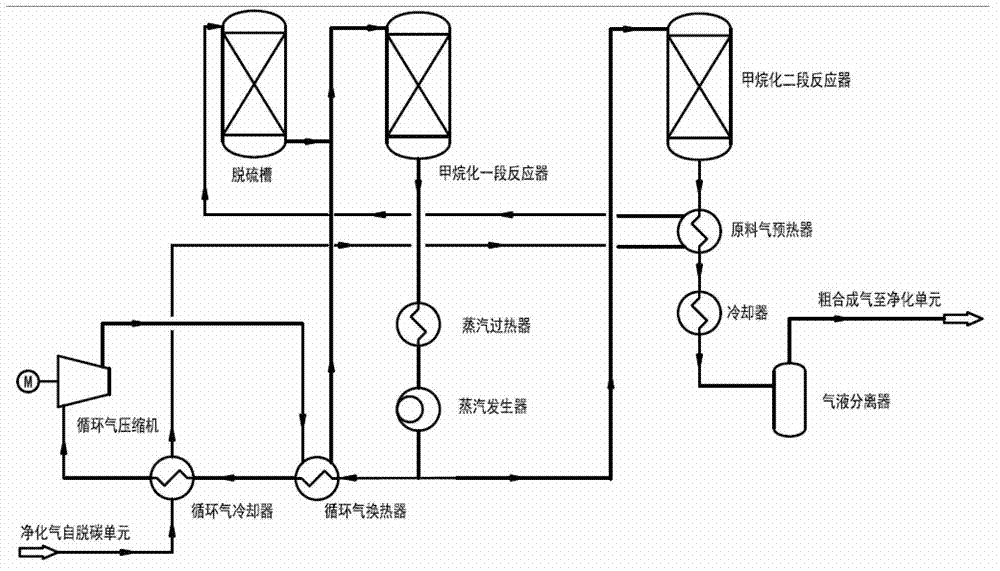

[0039] The semi-coke tail gas from the gas cabinet is compressed to 2.5MPa(G) by the raw gas compressor, and is preheated by the crude synthesis gas to 200~240°C, then enters the oxygen removal tank, and is removed from the raw gas by hydrogenation catalytic oxidation reaction. of oxygen. A large amount of heat is released during the deoxidation process. After the heated raw gas passes through the raw gas inlet preheater, low-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com