High-white-light luminous efficiency gallium nitride LED pipe core structure

A white light efficiency, gallium nitride technology, applied in electrical components, circuits, semiconductor devices, etc., to achieve the effect of improving white light efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

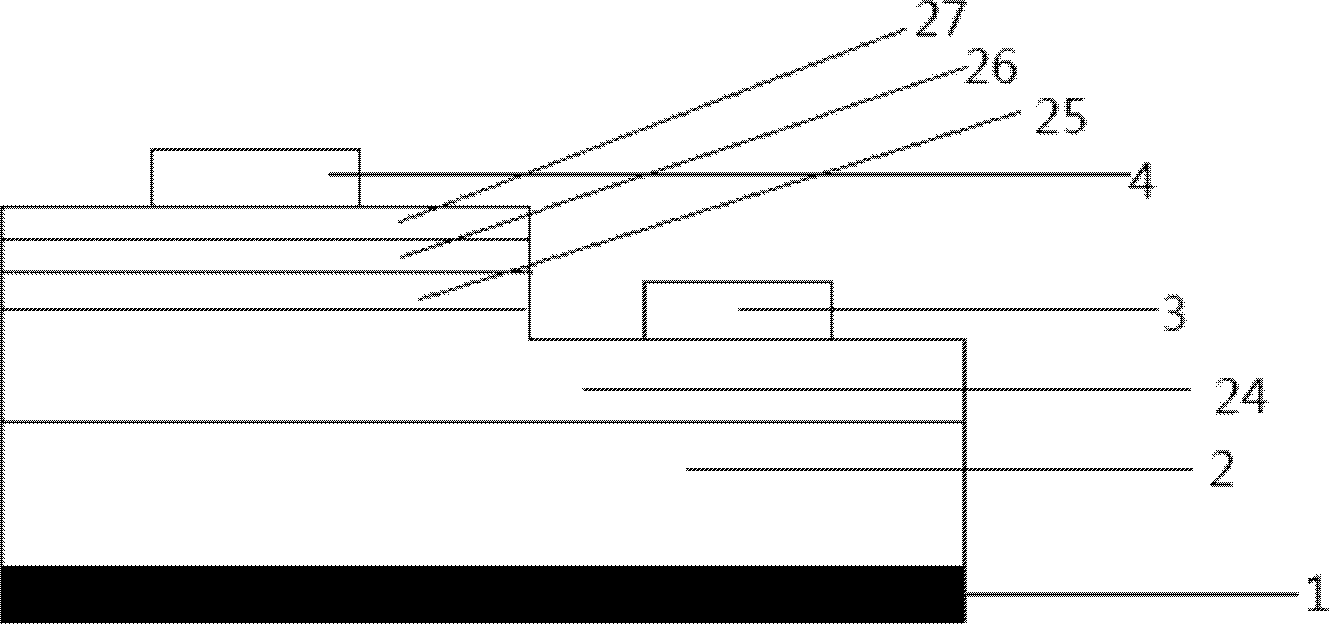

[0032] Embodiment 1, Gallium Nitride LED Tube Core Structure with Double Composite DBR Dielectric Film

[0033] The structure of GaN-based LED tube core with composite DBR dielectric reflective film is as follows: figure 2 shown. Including top-down P electrode 4, P-type current spreading layer 27, quantum well active region 25, N-type layer 24, N electrode 3, substrate 2, reflective film 1; Thin Polished Al 2 o 3 On the back of the substrate 2, the reflective film is a double composite DBR dielectric film made of TiO 2 , SiO 2 The two kinds of dielectric film materials are combined alternately, and the total number of dielectric film layers is 12 layers, a total of 6 pairs. Among them, the first three pairs of films are 460nm-band high-reflection films 23, and the optical thickness of each pair of films is 115nm, and the last three pairs of films are 580nm-band high-reflection films 22, and the optical thickness of each pair of films is 145nm. A metal Al thin film with ...

Embodiment 2

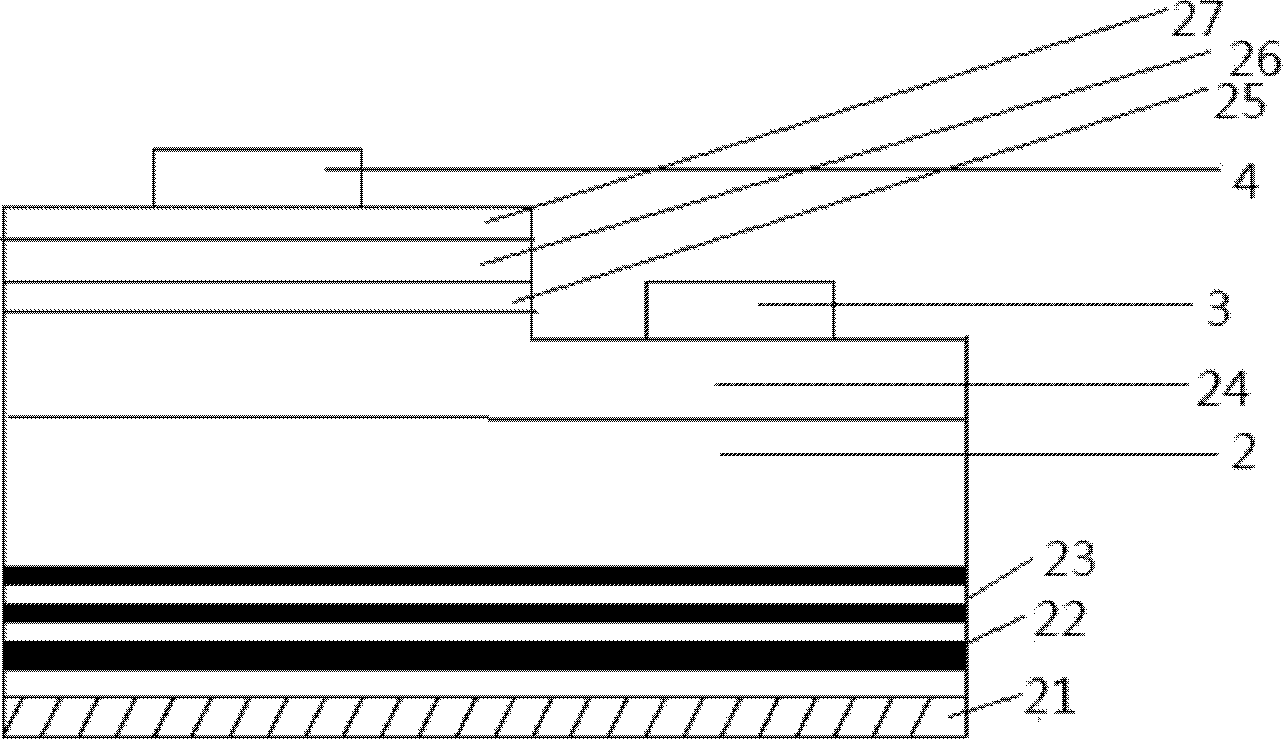

[0039] Example 2: Gallium Nitride LED Tube Core Structure of Triple Composite DBR Dielectric Film

[0040] The reflective film on the back of the substrate is a triple composite DBR dielectric film, and the triple composite DBR dielectric film is a composite film with high reflection of 460nm blue light, high reflection of 510nm green light and high reflection of 580nm yellow light; the entire DBR structure has three bands of high reflection film system. Using a dielectric film electron beam evaporation platform, in a vacuum of 10 -7 TiO deposited under torr pressure 2 , SiO 2 The refractive index of the medium is 2.35 and 1.46 respectively; sequentially evaporate TiO 2 , SiO 2 Alternate thin film, 12 layers in 6 periods, of which the film thickness of the first 2 periods is the 460nm band high reflection film system, the film optical thickness of each period is 115nm, and the next 2 periods are the 510nm band high reflection film system, and the film optical thickness of ...

Embodiment 3

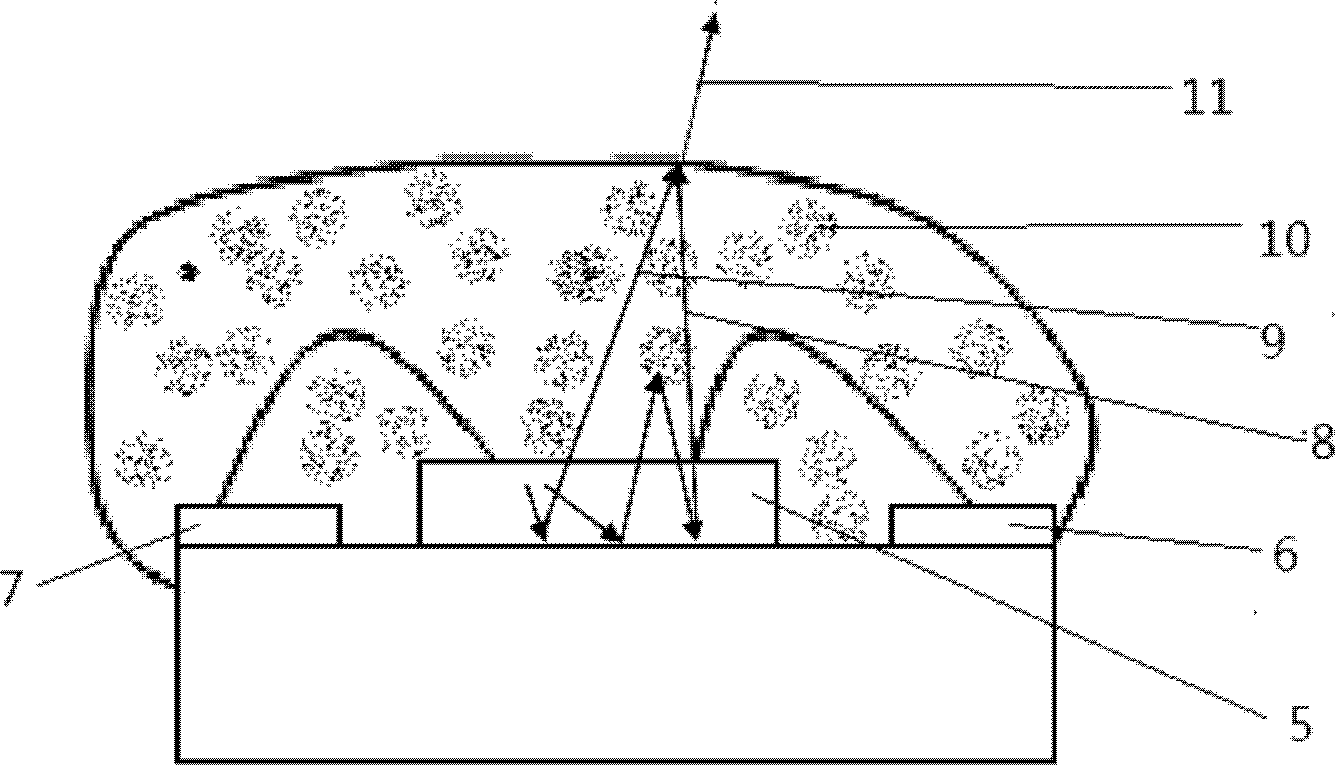

[0041] Embodiment 3: Application of Gallium Nitride LED Tube Core Structure in Embodiment 1

[0042] Such as image 3 As shown, an application example of GaN-based LED chip white light packaging with a composite DBR dielectric reflective film:

[0043] The GaN LED die of the above-mentioned embodiment 1 is solidified in a bowl according to the chip packaging process and connected to the positive electrode 7 and the negative electrode 6 of the base by welding wires, coated with yellow phosphor 10, and sealed with a rubber cap. Chip 5 multiple composite reflective film: the blue high reflection makes the blue light 9 recombined in the quantum well active area reflected by this layer and will be recombined with the phosphor powder or emitted from the front, and the yellow high reflectance makes the yellow light 8 already excited by the phosphor pass through The high-reflection layer is reflected back to the front exit surface, so that more blue light and yellow light are mixed i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com