Catalyst used for reforming synthesis gas of methane carbon dioxide and preparation method and application thereof

A carbon dioxide and catalyst technology, which is applied in the field of application of the catalyst in methane carbon dioxide, can solve problems such as cumbersome steps, and achieve the effects of simple preparation method, strong anti-coking performance, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

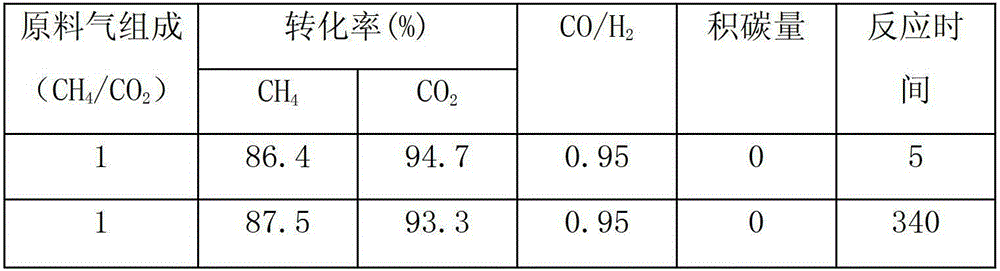

[0020] Example 1 coprecipitation preparation of methane carbon dioxide reforming synthesis gas catalyst of the present invention

[0021] Raw materials: First, according to the ratio of the molar amount of nickel nitrate: the molar amount of aluminum nitrate: the molar amount of magnesium nitrate: the volume ratio of distilled water is 1nmol: 26nmol: 16nmol: 100ml, add magnesium nitrate, nickel nitrate and aluminum nitrate to distilled water In, be made into solution L, be the sodium hydroxide solution N of 200ml of the standard configuration of 1mol / L by sodium hydroxide solution, be the sodium carbonate solution M of 200ml of the standard configuration of 0.1mol / L by the sodium carbonate solution, solution L and Slowly drop N into solution M to ensure that the pH value is 10, and at the same time with stirring, a mixed hydroxide and carbonate precipitate is formed; the precipitate is repeatedly washed with deionized water for 5-10 times, dried at 80°C for 18h, and 900°C ℃ ro...

example 2

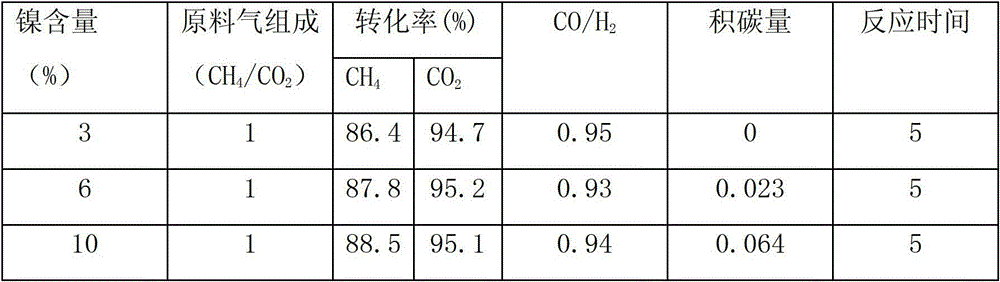

[0028] Methane carbon dioxide reforming of example 2 different nickel content synthesis gas catalyst

[0029] Catalyst preparation: according to the method of Example 1, the weighed amounts of nickel nitrate were 1nmol, 2nmol, and 3nmol respectively, and different Ni contents were 3%, 6%, and 9% methane carbon dioxide reforming synthesis gas catalysts.

[0030] Evaluation conditions

[0031] with 22%H 2 / N 2 The mixed gas is reduced for 30 minutes, and the volume composition of the raw gas is CH 4 / CO 2 is 1, the reaction temperature is 800°C, normal pressure, and the feed gas velocity is 40000h -1 . The evaluation results are shown in Table 2

[0032] Table 2. Reaction performance of methane carbon dioxide reforming catalysts with different nickel contents

[0033]

[0034] This example shows that the methane carbon dioxide reforming catalyst provided by the present invention has high catalytic activity when the nickel content is 3%-9%, and the carbon deposition amo...

example 3

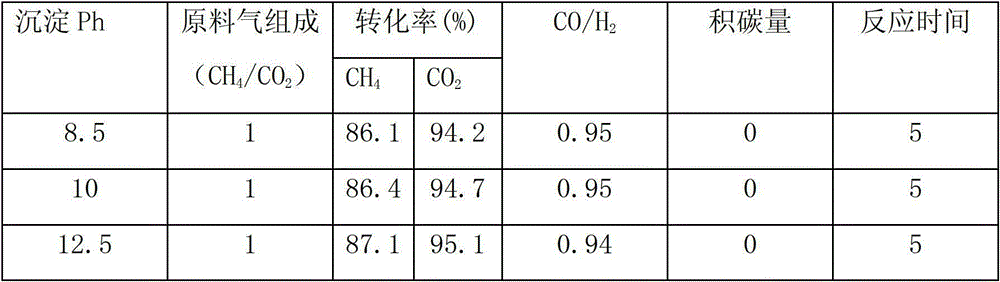

[0035] The methane carbon dioxide reforming catalyst reaction performance of different precipitation pH of example 3

[0036] Catalyst preparation: according to the method of Example 1, the precipitation Ph is 9.5, 10 and 10.5, and the catalysts for the synthesis gas reforming of methane and carbon dioxide with different precipitation Ph are prepared.

[0037] Evaluation conditions

[0038] with 22%H 2 / N 2 The mixed gas is reduced for 30 minutes, and the volume composition of the raw gas is CH 4 / CO 2 is 1, the reaction temperature is 800°C, normal pressure, and the feed gas velocity is 40000h -1 . The evaluation results are shown in Table 3

[0039] Table 3. Reaction performance of methane carbon dioxide reforming catalysts with different precipitated Ph

[0040]

[0041] This example shows that the methane carbon dioxide catalyst provided by the present invention has higher activity and stronger anti-coking performance under the precipitation condition Ph in the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com