Catalyst for coke oven gas double system synthesis gas and its preparation method and application

A technology for coke oven gas and catalyst, which is applied in the field of catalyst for double-integrated coke oven gas to syngas and its preparation field, can solve the problems of low carbon dioxide conversion rate and the like, and achieve high economic value, strong anti-carbon performance, and high catalytic activity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

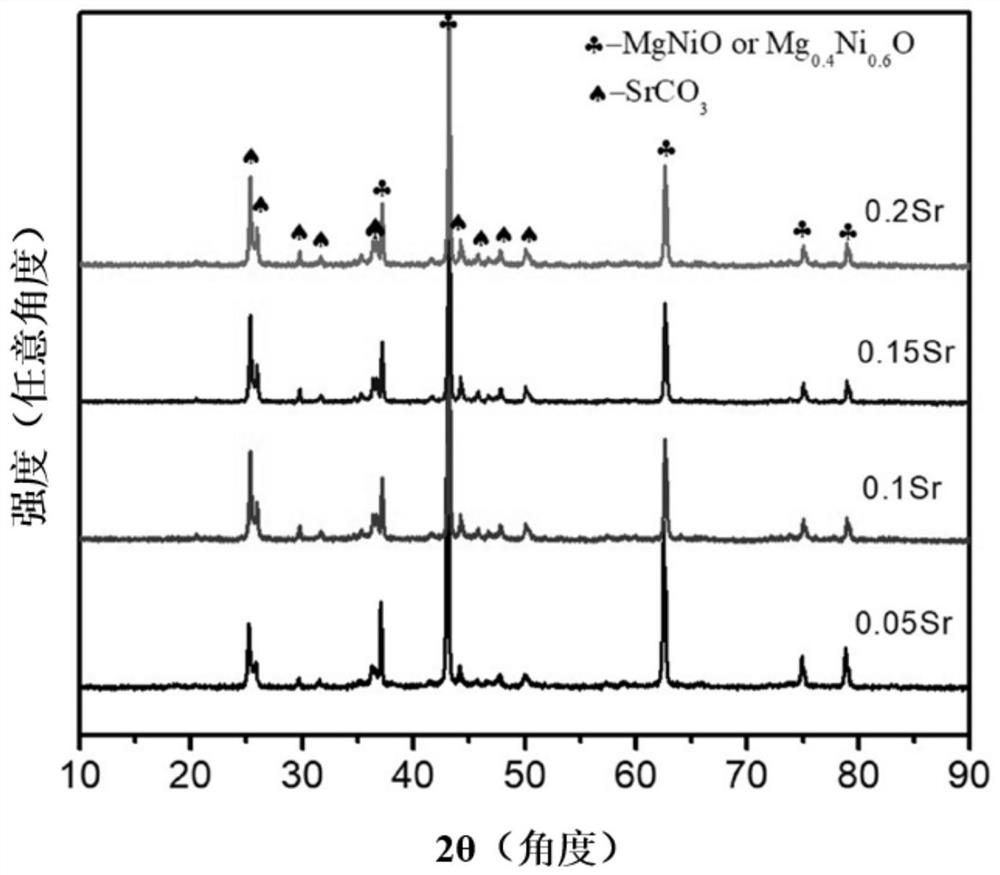

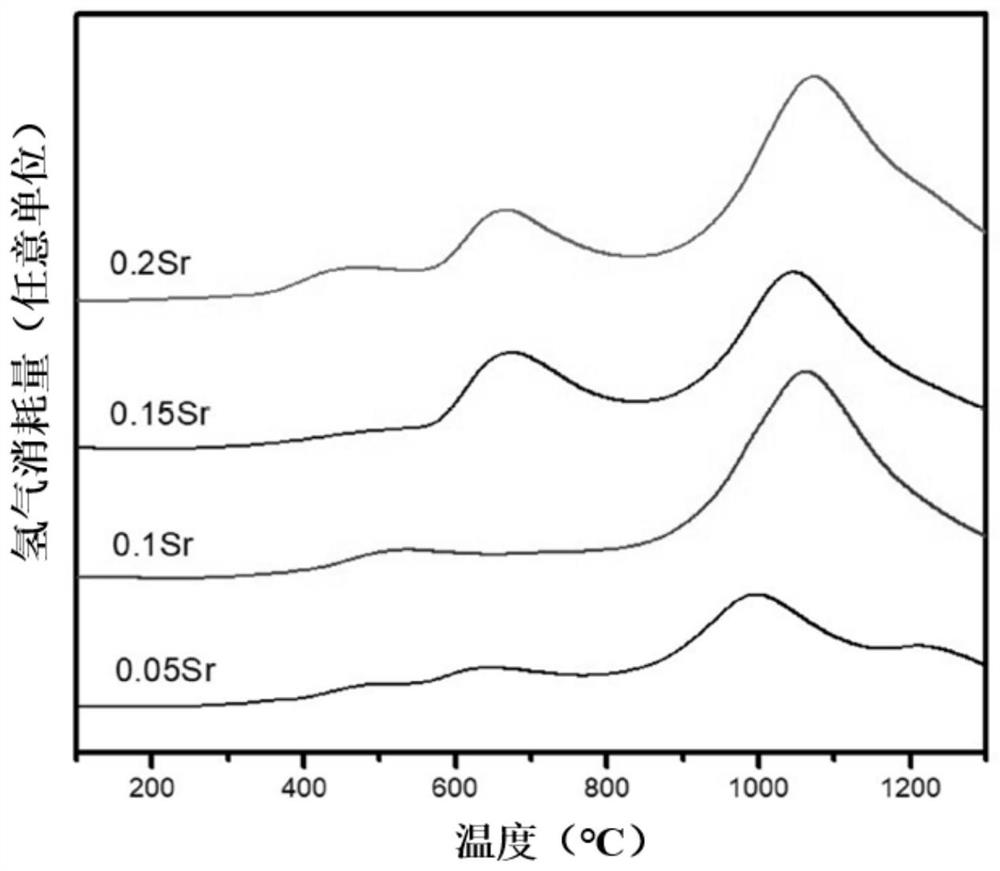

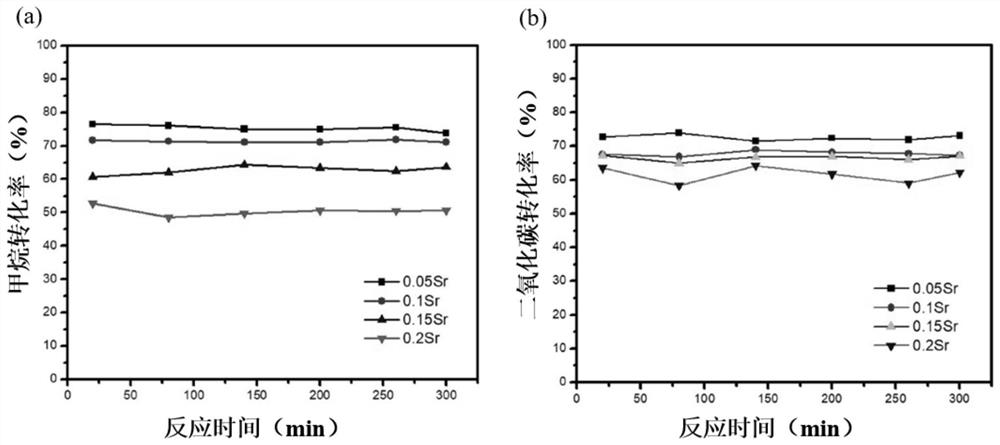

[0031] 0.25mol of Ni(NO 3 ) 2 ·6H 2O was dissolved in 100ml distilled water to form a nickel nitrate solution; 0.05mol of Sr(NO 3 ) 2 Dissolve in the nickel nitrate solution; then add 0.75mol of MgO in the mixed solution of nickel nitrate and strontium nitrate, fully stir evenly, then place it on a constant temperature magnetic stirrer at room temperature and fully stir for 12 hours, then let it stand for 12 hours, Then filter, put the obtained solid into a 110°C oven and dry for 3 hours, then take it out and put it into a muffle furnace for roasting, raise it to 800°C at a rate of 5°C per minute and keep it for 5 hours, then cool with the furnace to At room temperature, the catalyst was obtained. Grind the obtained catalyst into powder, and then use 1.5×10 8 The pressure of Pa presses it into a catalyst sheet. Put the catalyst sheet into the muffle furnace again, raise the temperature to 800°C at the same rate of 5°C per minute and keep it warm for 5 hours, cool down wi...

Embodiment 2

[0032] Embodiment 2 (one-step method)

[0033] Add 0.25mol of Ni(NO 3 ) 2 ·6H 2 O, 0.05mol of Sr(NO 3 ) 2 and 0.75mol of Mg(NO 3 ) 2 ·6H 2 O, stir until it dissolves evenly to form a mixed solution of nickel nitrate, strontium nitrate and magnesium nitrate. The mixed solution was fully stirred evenly, and slowly added (NH 4 ) 2 CO 3 solution, the dropwise addition was stopped immediately after a white precipitate appeared. It is then aged, filtered, washed, dried and made into Sr 0.05 Ni 0.25 / Mg 0.75 O catalyst. Then put it into a muffle furnace for roasting, raise the temperature to 800°C at a rate of 5°C per minute and keep it warm for 10 hours, and then cool to room temperature with the furnace. After taking it out, it is crushed and sieved to make catalyst particles of 60-80 mesh.

Embodiment 3

[0034] Embodiment 3 (co-precipitation method) sulfate

[0035] Add 0.25mol of Ni(NO 3 ) 2 ·6H 2 O, 0.05mol of Sr(NO 3 ) 2 and 0.75mol of MgSO 4 ·7H 2 O, stir until dissolved evenly to form a mixed solution of nickel nitrate, strontium sulfate and magnesium sulfate heptahydrate. The mixed solution was fully stirred evenly, and then added (NH 4 ) 2 CO 3 and NH 3 h 2 O, stop adding until precipitation occurs. After filtering and washing the precipitate, put it in an oven at 110°C, take it out after 12 hours, put it in a muffle furnace for roasting, raise the temperature to 800°C at a rate of 5°C per minute and keep it for 10 hours, then cool with the furnace, take it out and break it And sieve to make 60-80 mesh catalyst particles.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com