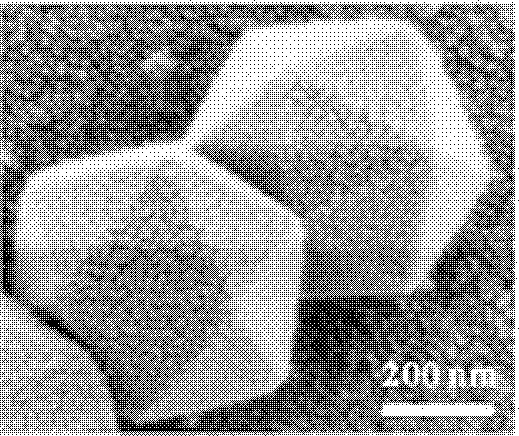

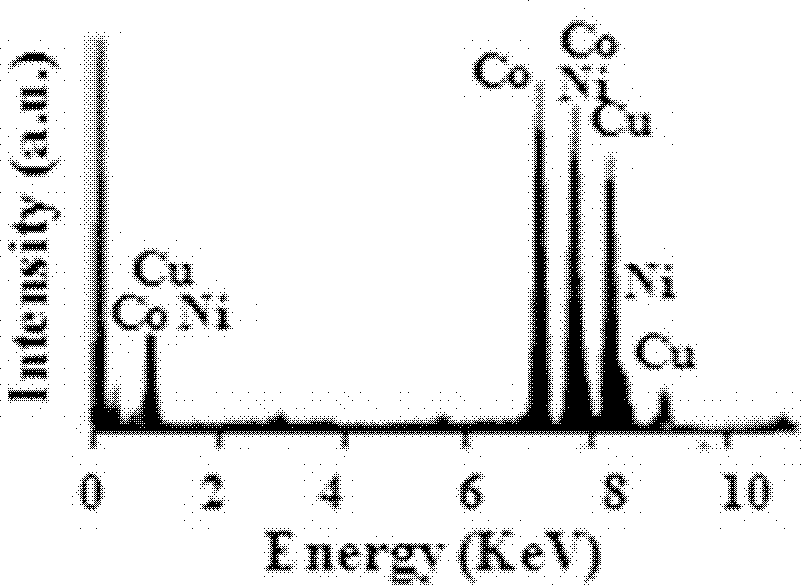

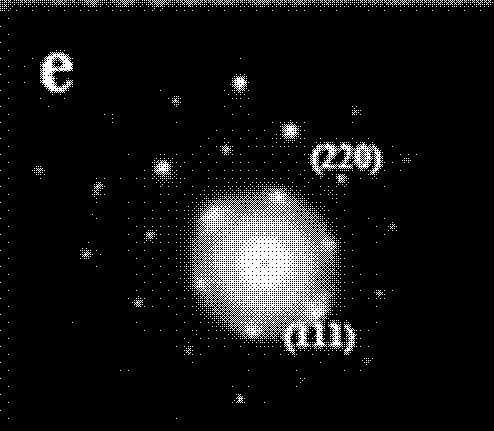

Preparation method of icosahedron crystalline nano nickel-cobalt alloy

A technology of icosahedron and nano-nickel, applied in the field of materials, to achieve the effects of convenient and simple product processing, stable product shape, and strong versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Preparation of Ni 48 co 52 A method for icosahedral nanoparticles comprising the steps of:

[0027] In the first step, the reactor is treated with dilute acid, filled with distilled water, and heated to 100°C. Then rinse with distilled water and dry for later use;

[0028] In the second step, add a straw of absolute ethanol to the clean reactor.

[0029] The third step is to accurately weigh 0.7465g of NiC 2 o 4 2H 2 O, 0.7472g of CoC 2 o 4 Put 1.2g of NaOH in a beaker, add 10ml of deionized water, stir well to dissolve, then transfer to a 25ml volumetric flask, and configure it as 0.12mol / L NiC 2 o 4 , 0.12mol / L CoC 2 o 4 , 1.2mol / L NaOH aqueous solution.

[0030] The fourth step, add about 1ml ethanol, 0.5ml NiC to the above solution 2 o 4 , 0.5ml CoC 2 o 4 , 1ml prepared NaOH, and then add 7ml 1,2-propanediol, ultrasonic 10min. Install the kettle jacket, and then heat in a muffle furnace at 210°C for 6h.

[0031] The fifth step, after the reaction i...

Embodiment 2

[0033] A preparation method of icosahedral crystalline nano-nickel-cobalt alloy, the method specifically comprising the following steps:

[0034] (1) Clean the reactor

[0035] The reaction kettle is treated with 0.1-0.2mol / L hydrochloric acid, filled with distilled water, and heated to 100°C. Then rinse with distilled water and dry for later use;

[0036] (2) Preparation of NaOH aqueous solution

[0037] Weigh a certain amount of NaOH and put it in a beaker, add deionized water, stir well to dissolve, transfer to a volumetric flask, dilute to the required volume, and make a 1.2mol / L NaOH aqueous solution;

[0038] (3) Preparation of Ni and Co aqueous solutions

[0039] Weigh an appropriate amount of NiC 2 o 4 2H 2 O, CoC 2 o 4 , put in a beaker and add an appropriate amount of deionized water, after it dissolves, transfer to a volumetric flask and dilute to the required volume. Stir evenly to make 0.12mol / L NiC 2 o 4 , 0.12mol / LCoC 2 o 4 aqueous solution, ready t...

Embodiment 3

[0044] A preparation method of icosahedral crystalline nano-nickel-cobalt alloy, the method specifically comprising the following steps:

[0045] (1) Clean the reactor

[0046] After the reaction kettle is treated with 0.1-0.2mol / L sulfuric acid, it is filled with distilled water and heated to 100°C. Then rinse with distilled water and dry for later use;

[0047] (2) Preparation of NaOH aqueous solution

[0048]Weigh a certain amount of NaOH and put it in a beaker, add deionized water, stir well to dissolve, transfer to a volumetric flask, dilute to the required volume, and make a 1.2mol / L NaOH aqueous solution;

[0049] (3) Preparation of Ni and Co aqueous solutions

[0050] Weigh an appropriate amount of NiC 2 o 4 2H 2 O, CoC 2 o 4 , put in a beaker and add an appropriate amount of deionized water, after it dissolves, transfer to a volumetric flask and dilute to the required volume. Stir evenly to make 0.12mol / L NiC 2 o 4 , 0.12mol / LCoC 2 o 4 aqueous solution, r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com