Steam-cured high-performance foam concrete block, production method and application thereof

A foamed concrete, high-performance technology, applied in the field of lightweight and energy-saving building wall materials, can solve the problems of low strength, easy pulverization, large shrinkage, etc., and achieve the effects of improving waterproof performance, simple production process, and reducing weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] A steam-cured high-performance foam concrete block is prepared by the following steps:

[0038] 1) Weigh 1kg of Henan Huatai HTQ-1 composite foaming agent, add it to the foaming machine, and add 40kg of tap water to fully foam with compressed air;

[0039] 2) At the same time, weigh out 510kg of cement (P.O42.5R; the same below), 75kg of S95 slag powder, 45kg of sand, and non-slow aggregation carboxylic acid superplasticizer (Guangdong Yuehe HPG-R type; the same below) 6.3kg, Add 190kg of water to the mixer and mix and stir. Stir slowly for 0.5min, then quickly stir for about 1.5min, then add 8kg of curing agent (5.6kg of sodium chloride, 2.4kg of calcium hydroxide), and then stir quickly for 2min to make the slurry uniform;

[0040] 3) The foam that has been foamed in step 1) is blown into the uniformly stirred slurry through compressed air and mixed with the slurry, and then stirred slowly for about 1.5 minutes to make the slurry become a uniform high-performance foamed conc...

Embodiment 2

[0044] A steam-cured high-performance foam concrete block is prepared by the following steps:

[0045] 1) Weigh 0.8kg of Henan Huatai HTQ-1 composite foaming agent, add it to the foaming machine, and add 35kg of tap water to fully foam with compressed air;

[0046] 2) At the same time, weigh 582kg of cement, 86kg of S95 slag powder, 51kg of sand, 7.3kg of non-slow coagulation carboxylic acid superplasticizer, and 220kg of water, and add them to the mixer to mix and stir. Stir slowly for 0.5min, then quickly stir for about 1.5min. Then add 9kg of curing agent (6.3kg of sodium chloride, 2.7kg of calcium hydroxide), and then quickly stir for 2min to make the slurry uniform;

[0047] The remaining steps are the same as steps 3)-5) of Example 1. The dry density of the steam-cured high-performance foam concrete block is 800kg / m 3 .

Embodiment 3

[0049] A steam-cured high-performance foam concrete block is prepared by the following steps:

[0050] 1) Weigh 0.7kg of Henan Huatai HTQ-1 composite foaming agent, add it to the foaming machine, and add 30kg of tap water to fully foam with compressed air;

[0051] 2) At the same time, weigh 655kg of cement, 96kg of S95 slag powder, 58kg of sand, 8.3kg of non-slow coagulation carboxylic acid superplasticizer, and 250kg of water, and add them to the mixer to mix and stir. Stir slowly for 0.5min, then quickly stir for about 1.5min. Then add 10.0kg of curing agent (7.0kg of sodium chloride, 3.0kg of calcium hydroxide), and then quickly stir for 2min to make the slurry uniform;

[0052] The remaining steps are the same as steps 3)-5) of Example 1. The dry density of the steam-cured high-performance foam concrete block is 900kg / m 3 .

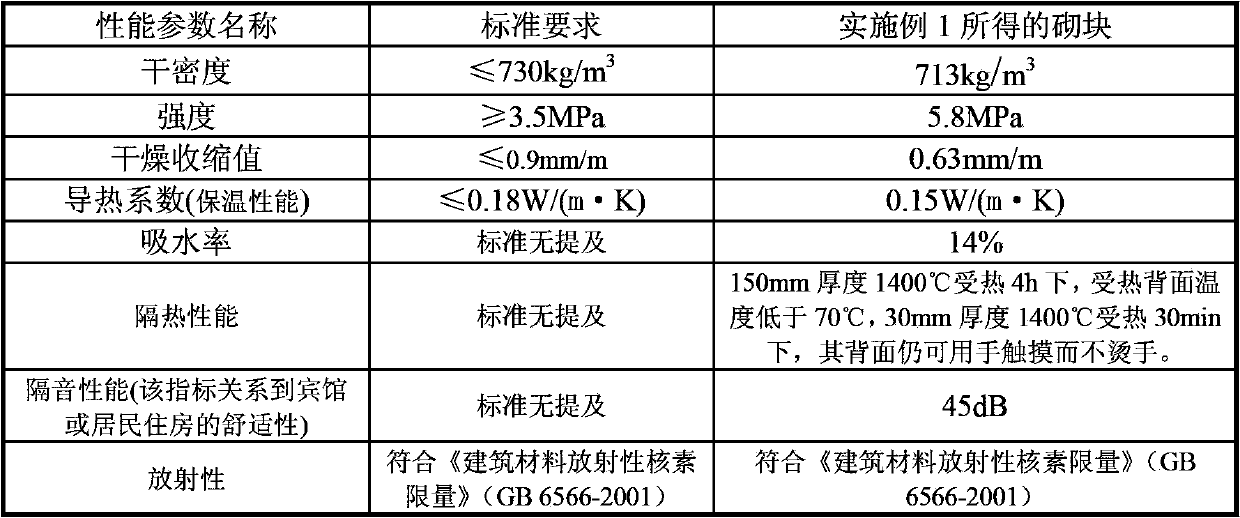

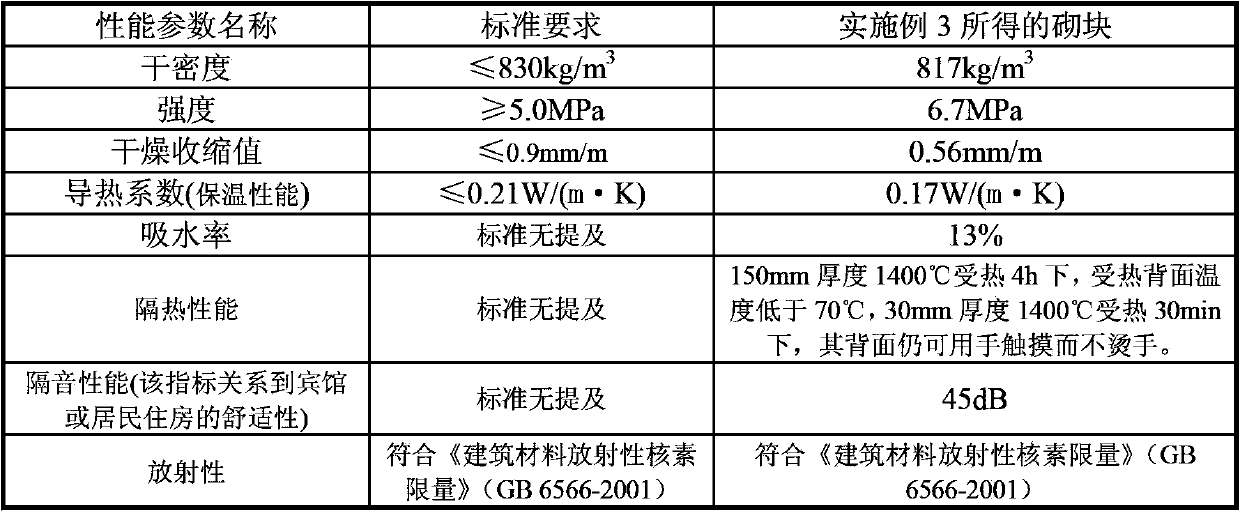

[0053] With reference to the requirements of "Foam Concrete Blocks" (JC / T1062-2007), the specific performance indicators of the steam-cured high-performanc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com