Controlled release nitrogen-containing controlled release fertilizer special for sugarcane

A technology of controlled-release fertilizer and controlled-release nitrogen, applied in the field of controlled-release fertilizer and sugarcane-specific controlled-release fertilizer, can solve the problems of aggravated nutrient ion fixation, long sugarcane growth period, low fertilizer utilization rate, etc., and achieve the effect of nutrient controlled release Good, long nutrient release period, comprehensive nutrient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

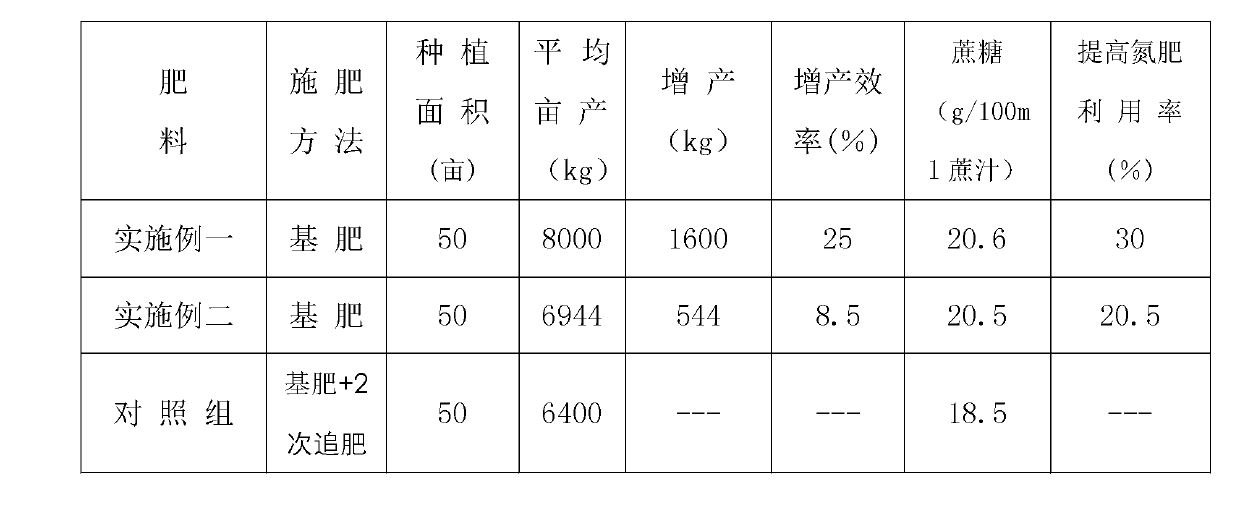

Embodiment 1

[0043] Raw materials: 130 kg of film-forming polymer-coated urea with a release period of 180 days, 125 kg of film-forming polymer-coated urea with a release period of 120 days, and 60 kg of film-forming polymer-coated urea with a release period of 60 days kg, urea 30 kg, diammonium phosphate 195 kg, potassium sulfate 455 kg, zinc sulfate 5 kg, magnesium sulfate 4 kg.

[0044] Put the above-mentioned raw materials into the blender, mix thoroughly, and then send the mixed fertilizer into the metering and packaging machine for metering and packaging.

Embodiment 2

[0046] Raw materials: 130 kg of film-forming polymer-coated urea with a release period of 180 days, 120 kg of film-forming polymer-coated urea with a release period of 120 days, and 50 kg of film-forming polymer-coated urea with a release period of 60 days , 35 kg of urea, 200 kg of monoammonium phosphate, 460 kg of potassium chloride, 5 kg of zinc sulfate, and 4 kg of magnesium sulfate.

[0047] Put the above-mentioned raw materials into the blender, mix thoroughly, and then send the mixed fertilizer into the metering and packaging machine for metering and packaging.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com