Silica with surface subjected to polymerization modification, and preparation method thereof

A silicon dioxide and modification technology, which is applied in the treatment of dyed polymer organic compounds, fibrous fillers, etc., can solve the problem that the improvement of the dispersion of silicon dioxide is not obvious, the modification effect is poor, and it is easy to be decomposed by water, etc. problems, to achieve the effect of solving poor product dispersibility, reducing average particle size, avoiding pollution and recycling problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

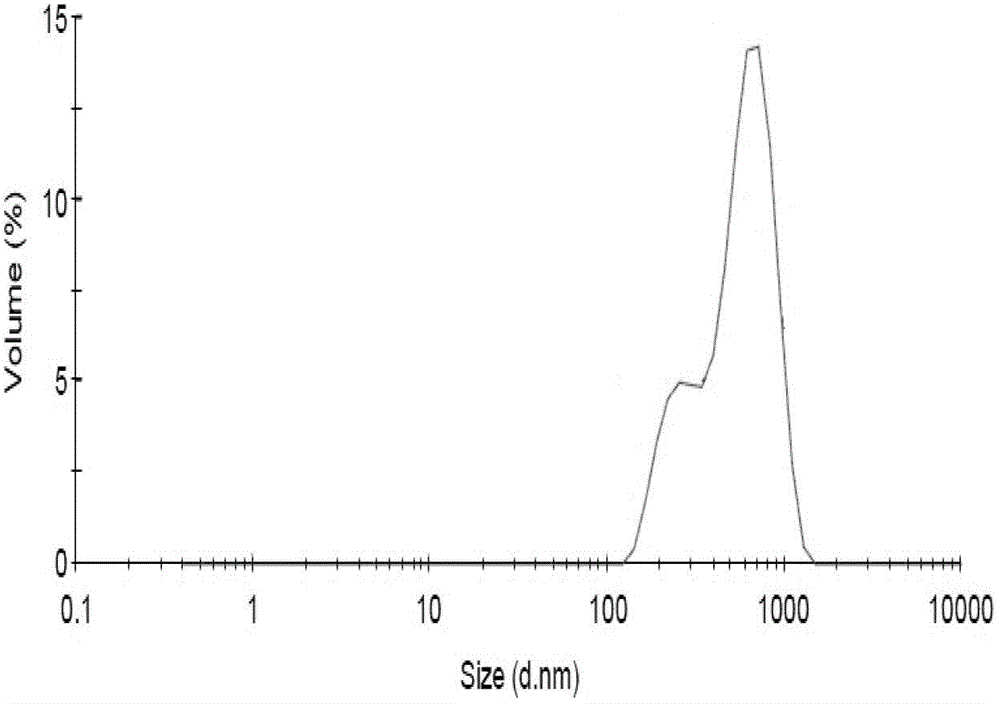

[0021] Add 20 g of the undried silica filter cake directly prepared by the precipitation method into 80 ml of deionized water, stir evenly, and disperse ultrasonically for 20 minutes to form a silica suspension with a particle size of 1 μm;

[0022] Dissolve 0.3g of acrylic acid in 10ml of deionized water, pour it into a three-necked flask together with the previously prepared silica suspension, heat to 85°C while stirring, and keep it warm for 1 hour;

[0023] Weigh 0.2g of potassium persulfate and dissolve it in 40ml of deionized water, pour it into a three-necked flask, and react in a water bath at a constant temperature for 2 hours while stirring;

[0024] After the reaction was completed, the temperature was lowered, washed, suction filtered, and dried to obtain surface polymerization-modified silica with an average particle diameter of 306.3 nm.

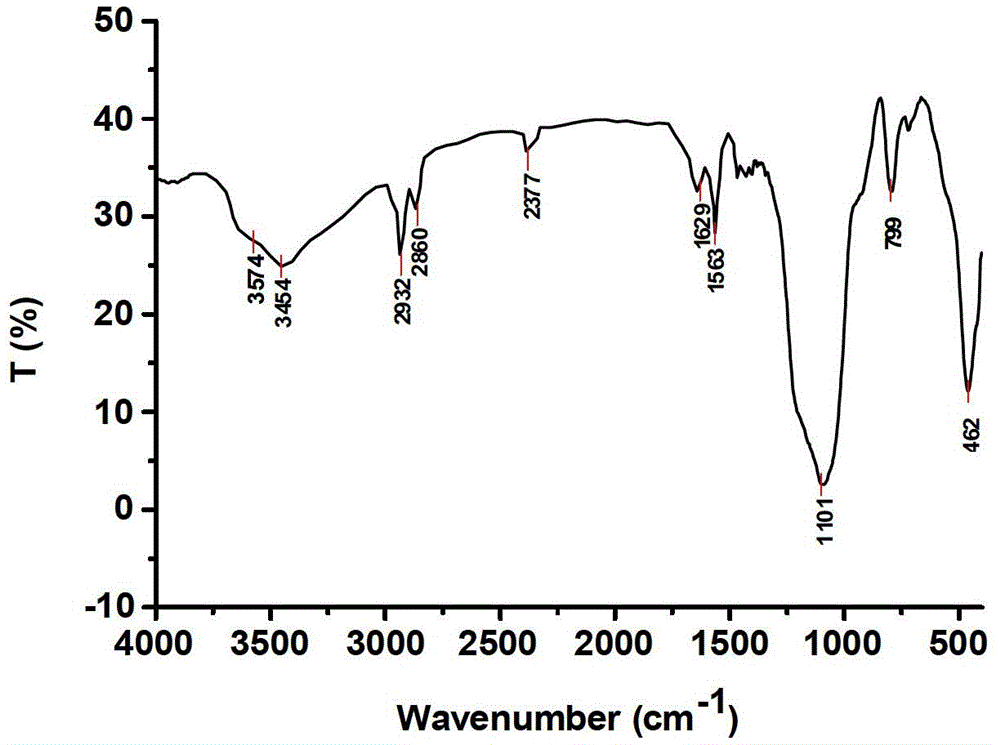

[0025] figure 1 It is the infrared spectrogram of surface polymerization modified silica, which shows that acrylic acid has ...

Embodiment 2

[0027] Take 20 g of the undried silica filter cake directly prepared by the precipitation method, add it to 100 ml of deionized water, stir evenly, and disperse ultrasonically for 10 minutes to form a silica suspension with a particle size of 1 μm;

[0028] Dissolve 0.2g of acrylic acid in 6ml of deionized water, pour it into a three-necked flask together with the previously prepared silica suspension, heat to 75°C while stirring, and keep it warm for 1 hour;

[0029] Weigh 0.1g of potassium persulfate and dissolve it in 30ml of deionized water, pour it into a three-necked flask, and react in a water bath at a constant temperature for 2.5 hours while stirring;

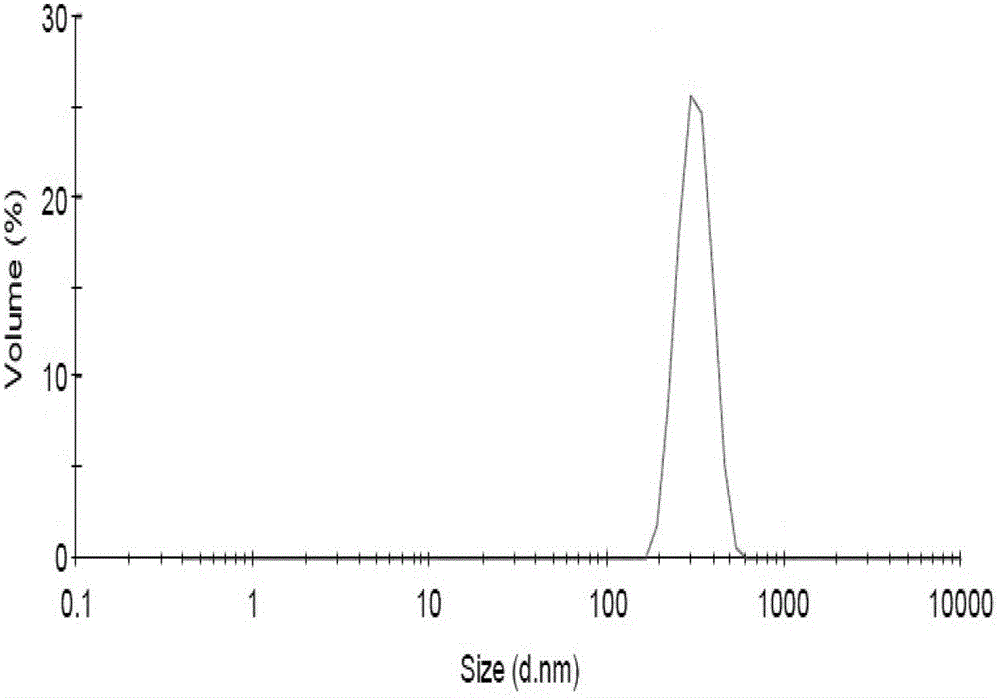

[0030] After the reaction was completed, the temperature was lowered, washed, suction filtered, and dried to obtain surface polymerization-modified silica with an average particle diameter of 310.2 nm.

[0031] Particle size distribution analysis: d(0.1): 228.9nm, d(0.5): 292.1nm, d(0.9): 373.5nm; infrared spectrum ana...

Embodiment 3

[0033] Add 20 g of the undried silica filter cake directly prepared by the precipitation method into 90 ml of deionized water, stir evenly, and disperse ultrasonically for 10 minutes to form a silica suspension with a particle size of 1 μm;

[0034] Dissolve 0.35g of acrylic acid in 10ml of deionized water, pour it into a three-necked flask together with the previously prepared silica suspension, heat to 60°C while stirring, and keep it warm for 2 hours;

[0035] Weigh 0.4g of potassium persulfate and dissolve it in 50ml of deionized water, pour it into a three-necked flask, and react in a water bath at a constant temperature for 2.5 hours while stirring;

[0036] After the reaction is completed, the temperature is lowered, washed, suction filtered, and dried to obtain surface polymerization-modified silica with an average particle diameter of 316.6 nm.

[0037] Particle size distribution analysis: d(0.1): 236.8nm, d(0.5): 288.7nm, d(0.9): 390.2nm; infrared spectrum analysis, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com