Well-cementing and self-healing cement slurry for oil-gas field

A self-healing technology for oil and gas fields, applied in the direction of drilling compositions, chemical instruments and methods, etc., can solve the problems of reduced seepage and anti-seepage performance, inability to function, interlayer fluid crossing, etc., and achieve settlement stability Good, adjustable thickening time, and improved mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] A kind of self-healing cement slurry for cementing in oil and gas fields, its raw material composition and quality are respectively:

[0032] The quality of grade G oil well cement is 800g; acrylamide-acrylamide-2-methylpropanesulfonate sodium copolymer 16g; oil content is 10% natural oil latex 80g; OP-40 stabilizer 2g; lignin sulfonate 8g; tributyl phosphate defoamer 4g; citric acid 0.24g; water 282g.

[0033] The weighing amount of slurry mixing water is the total water amount calculated according to the water-cement ratio, and then subtract the water content in each additive.

[0034] The preparation method of the present invention is as follows: uniformly mix each additive component at a low shear rate, then weigh a certain amount of cement and add it to the slurry mixing liquid, and mix the slurry according to the API standard to obtain the present invention.

Embodiment 2

[0036] A kind of self-healing cement slurry for cementing in oil and gas fields, its raw material composition and quality are respectively:

[0037] The quality of grade G oil well cement is 800g, 16g of acrylamide-acrylamide-2-sodium methylpropane sulfonate copolymer; 2g of OP-40 stabilizer; 80g of styrene-butadiene oil-containing latex with an oil content of 10%; lignosulfonic acid Salt 8g; tributyl phosphate defoamer 4g; citric acid 0.24g; water 282g.

Embodiment 3

[0039] A kind of self-healing cement slurry for cementing in oil and gas fields, its raw material composition and quality are respectively:

[0040] The quality of grade G oil well cement is 800g, 24g of acrylamide-acrylamide-2-methylpropanesulfonate sodium copolymer; 2g of OP-40 stabilizer; 80g of natural oil latex with an oil content of 10%; lignosulfonate 8g; silicone defoamer 4g; citric acid 2.4g; water 271.5g.

[0041] Verify the use effect of the present invention by comparative example below:

[0042] Grade G oil well cement 800g, acrylamide-acrylamide-2-methylpropanesulfonate sodium copolymer 16g; lignin sulfonate 8g; tributyl phosphate 4g; citric acid 0.24g; tap water 324g.

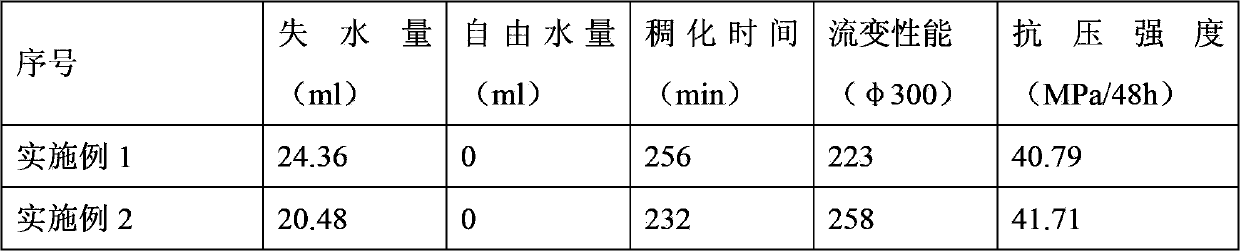

[0043] Table 1 Basic properties of cement slurry

[0044]

[0045]

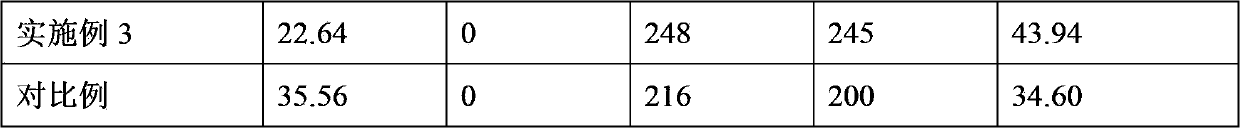

[0046] Table 2 Self-healing performance of cement slurry

[0047]

[0048] Note: "—" in Table 2 indicates that self-healing cannot be achieved.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com