Coal pyrolysis method for increasing oil yield by introducing fusel

A coal pyrolysis and fusel alcohol technology, which is applied in the petroleum industry, direct heating carbonization, coking oven, etc., can solve the problems of secondary cracking reaction and free radical polymerization reaction, difficult to meet market demand, and reduction of tar yield, etc., to achieve Low cost, easy operation and control, and the effect of reducing residence time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

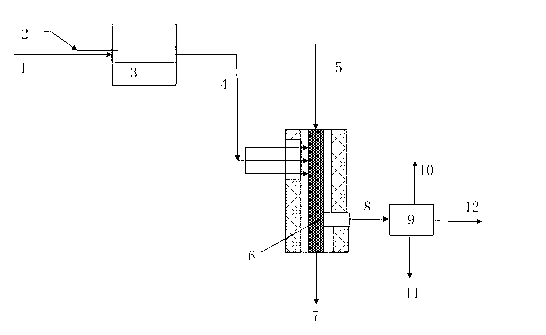

[0023] Such as figure 1 Shown, a kind of coal pyrolysis method that feeds fusel alcohol to improve oil yield may further comprise the steps:

[0024] (1) Fusel alcohol uses the waste liquid of fusel alcohol produced in the process of producing methanol from syngas. Its main components are methanol, ethanol, propanol and amyl alcohol, etc. Fusel alcohol 2 is pumped and sprayed into preheater 3 at a temperature of 240-350 Preheating at ℃ is the fusel alcohol vapor for standby; the carrier gas is preheated to 240-350 ℃ in the preheater 3;

[0025] (2) The mixed gas of fusel alcohol vapor and carrier gas enters the coal pyrolysis reactor 6, and the coal 5 reacts with the mixed gas of 4 fusel alcohol carrier gas in the pyrolysis reactor 6, and a pyrolysis reaction occurs in the reactor at a reaction temperature of 450 ~650℃; Reaction time 10~30min;

[0026] (3) The raw coal gas produced by pyrolysis is exported from the middle and lower part of the pyrolysis reactor, and enters t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com