Scalpel for circularly and continuously resecting anterior capsules of lenses

A continuous, lens technology, applied in ophthalmic surgery and other directions, can solve the problems of poor operation stability, damaged corneal endothelium, high cost, etc., achieve strong controllability, reduce interference, and reduce postoperative complications.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

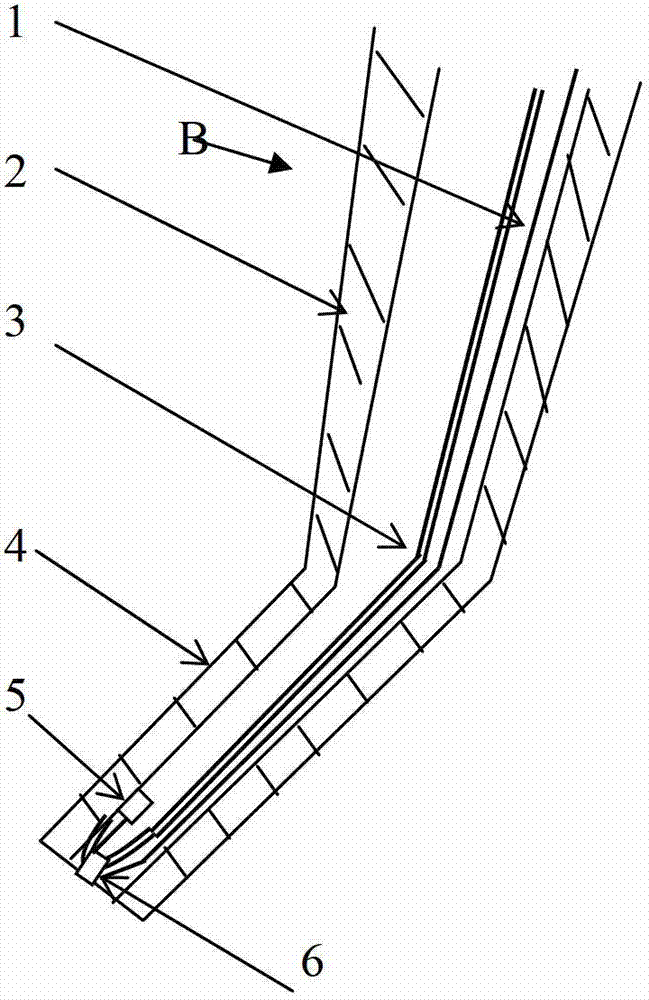

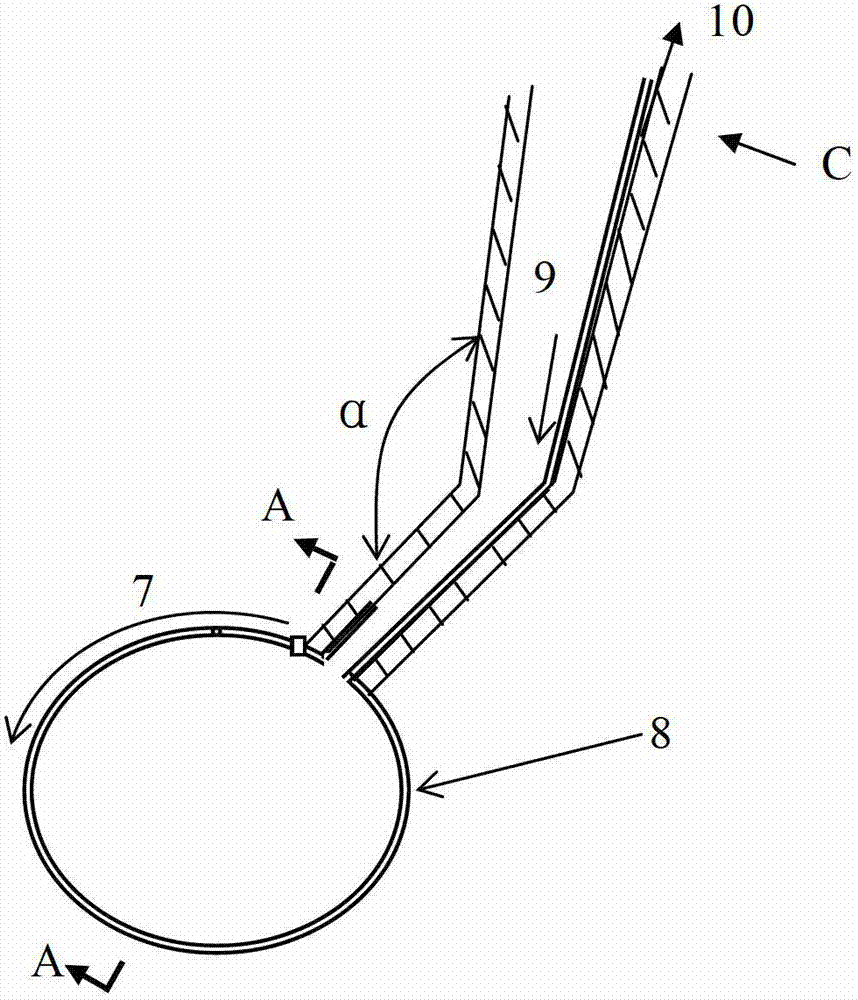

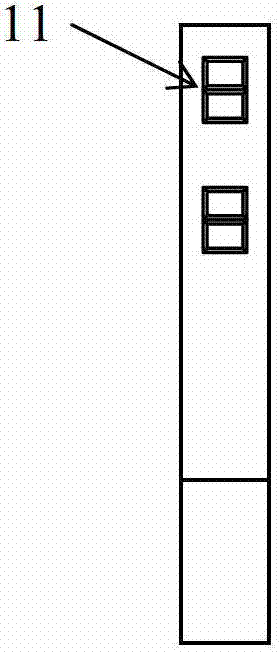

[0027] Such as figure 1 , image 3 As shown, a scalpel for continuously cutting the anterior capsule of the lens in a ring, including a hollow handle 2, the front end of the handle is a segment of outward (left) inclined segment 4, the inclination between the handle and the segment segment Angle α is 120°-150° ( figure 2 ), the memory alloy strip 3 (nickel-titanium alloy) is built in the cutter head. One end of the memory alloy strip is fixedly connected to the middle and outer sides of the cutter head mouth. The telescopic electric mechanism of the memory alloy strip is connected through a group of button switches 11 ( image 3 ) to realize the extension or retraction of the memory alloy strip. The curved memory alloy strip in the cutter head is covered with a sliding cutter 6, and the sliding cutter is connected with two sections of pulling wires 1, one of which is wound on a retractable pulley 5 (capable of rebounding) that is fixedly connected to the outer side of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com