Method for preparing strontium-zinc-iron ternary composite magnetic material

A ternary composite, magnetic material technology, applied in the direction of inorganic material magnetism and other directions, can solve the problems of complex preparation process steps, increase production cost, and high production cost, and achieve the effects of simple process steps, improved production efficiency, and low production cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

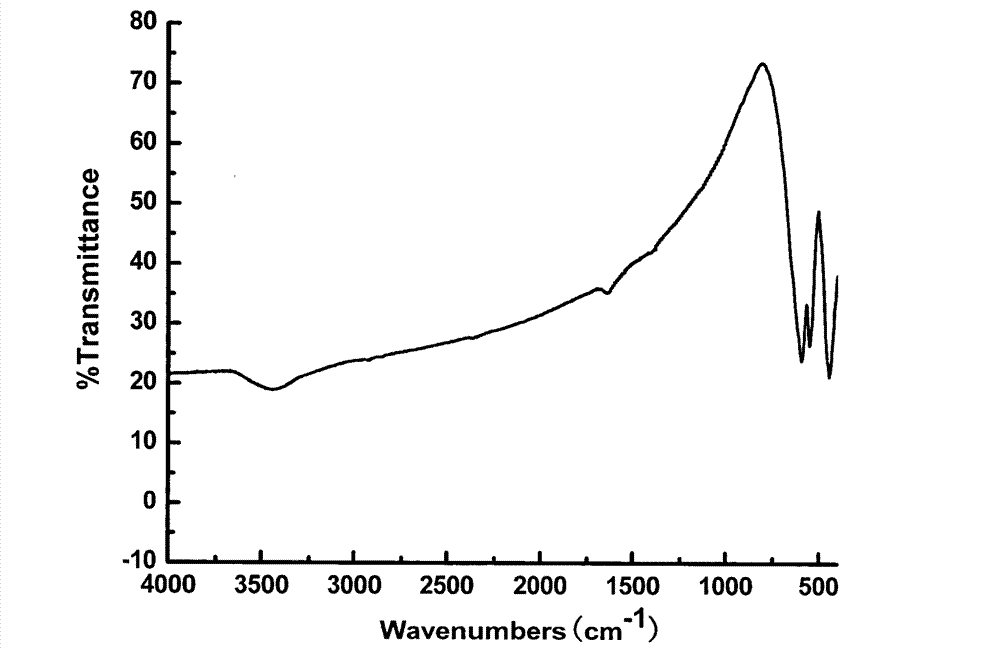

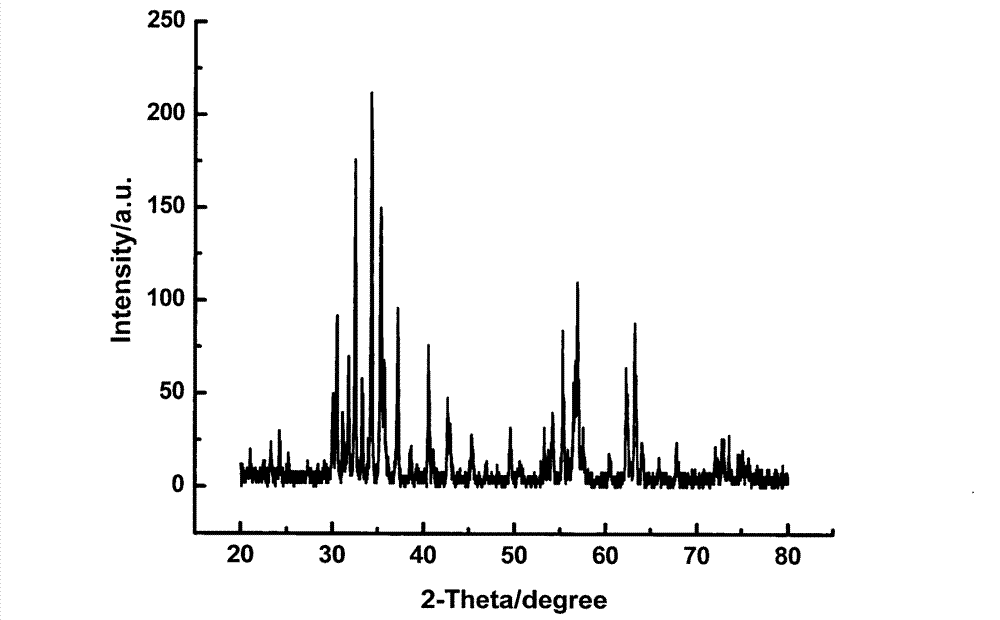

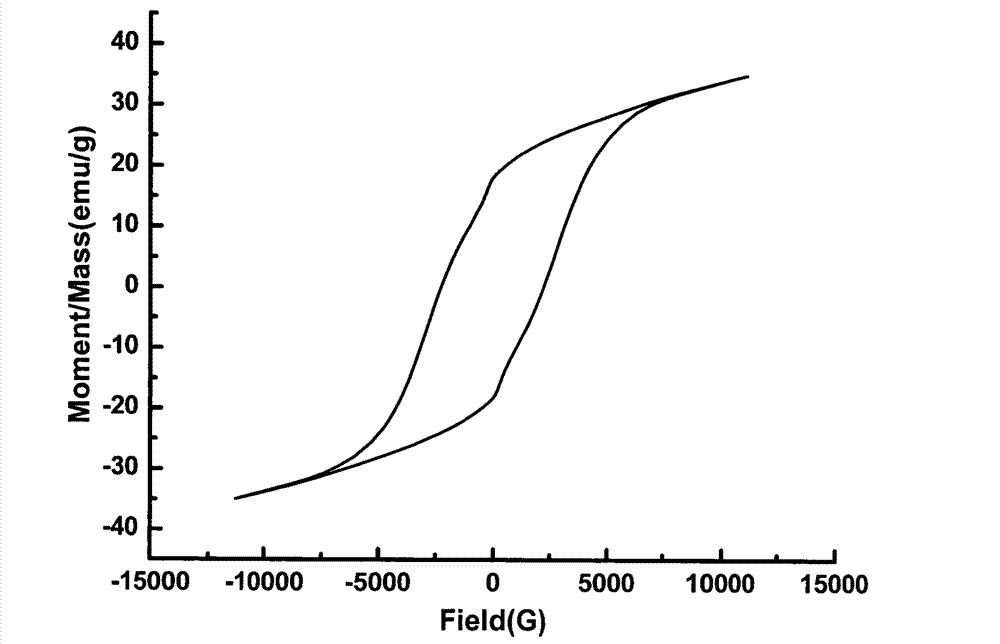

[0023] A method for preparing a strontium-zinc-iron ternary composite magnetic material, the specific steps of which are as follows:

[0024] (1) Preparation of strontium-zinc-iron ternary composite magnetic material precursor

[0025] Using strontium chloride hexahydrate, zinc chloride and ferric chloride hexahydrate as raw materials, the molar ratio of strontium in strontium chloride hexahydrate: zinc in zinc chloride: iron in ferric chloride hexahydrate is 1: In the ratio of 1:14, add strontium chloride hexahydrate, zinc chloride and ferric chloride hexahydrate into the first container in turn, and then add strontium chloride hexahydrate, zinc chloride and ferric chloride hexahydrate into the first container. The total mass of raw materials (g): the volume (mL) ratio of distilled water is 1: 4.0, add distilled water, stir until strontium chloride hexahydrate, zinc chloride and ferric chloride hexahydrate are all dissolved, and a homogeneous mixed solution is obtained . Us...

Embodiment 2

[0029] A method for preparing a strontium-zinc-iron ternary composite magnetic material, the specific steps of which are as follows:

[0030] (1) Preparation of strontium-zinc-iron ternary composite magnetic material precursor

[0031] With strontium chloride hexahydrate, zinc chloride and ferric chloride hexahydrate as raw materials, the molar ratio of strontium in strontium chloride hexahydrate: zinc in zinc chloride: iron in ferric chloride hexahydrate is 0.5: In the ratio of 0.5:13, add strontium chloride hexahydrate, zinc chloride and ferric chloride hexahydrate into the first container in turn, and then add strontium chloride hexahydrate, zinc chloride and ferric chloride hexahydrate into the first container. The total mass of raw materials (g): the volume (mL) ratio of distilled water is 1: 3.0, add distilled water, stir until strontium chloride hexahydrate, zinc chloride and ferric chloride hexahydrate are all dissolved, and a homogeneous mixed solution is obtained . ...

Embodiment 3

[0035] A method for preparing a strontium-zinc-iron ternary composite magnetic material, the specific steps of which are as follows:

[0036] (1) Preparation of strontium-zinc-iron ternary composite magnetic material precursor

[0037] With strontium chloride hexahydrate, zinc chloride and ferric chloride hexahydrate as raw materials, the molar ratio of strontium in strontium chloride hexahydrate: zinc in zinc chloride: iron in ferric chloride hexahydrate is 1.5: In the ratio of 1.5:15, add strontium chloride hexahydrate, zinc chloride and ferric chloride hexahydrate into the first container in sequence, and then add strontium chloride hexahydrate, zinc chloride and ferric chloride hexahydrate into the first container. The total mass of raw materials (g): the volume (mL) ratio of distilled water is 1: 5.0, add distilled water, stir until strontium chloride hexahydrate, zinc chloride and ferric chloride hexahydrate are all dissolved, and a homogeneous mixed solution is obtained...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com