Method for cooling mass concrete

A large-volume concrete and phase change temperature range technology, which is applied in the processing of building materials, construction, building construction, etc., can solve problems such as insufficient phase change enthalpy, reduced heat absorption capacity of cooling water, and rise in concrete temperature. Insufficient phase change enthalpy, improved heat utilization rate, and reduced cooling rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

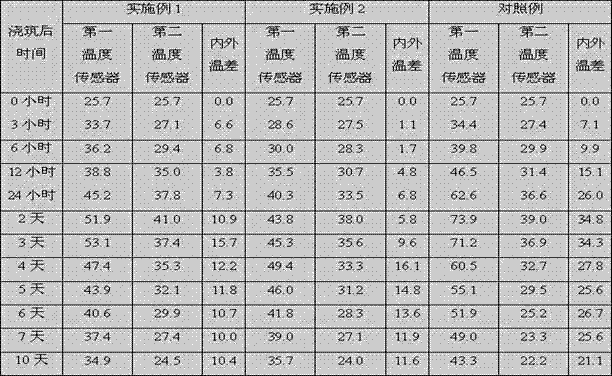

Embodiment 1

[0047] The raw materials and weight ratio of mass concrete in embodiment 1 are cement 300 kg / m 3 , fly ash 90 kg / m 3 , mineral powder 80 kg / m 3 , sand 680 kg / m 3 , Stone 1090 kg / m 3 , water 160 kg / m 3 , water reducer 6 kg / m 3 . The feeding temperature of each raw material before stirring is 20°C. Weigh each raw material according to the above weight ratio, and make concrete slurry after stirring. The cement used is ordinary Portland cement with a strength grade of 42.5; the fly ash is Class I fly ash; the mineral powder is S95 grade mineral powder; the sand is river sand with a fineness modulus of 2.6 and a mud content of 2%. ; The stone is 5~31.5mm continuous gradation, the water reducer is polycarboxylate water reducer, the solid content is 20%, and the water reducing rate is 23%.

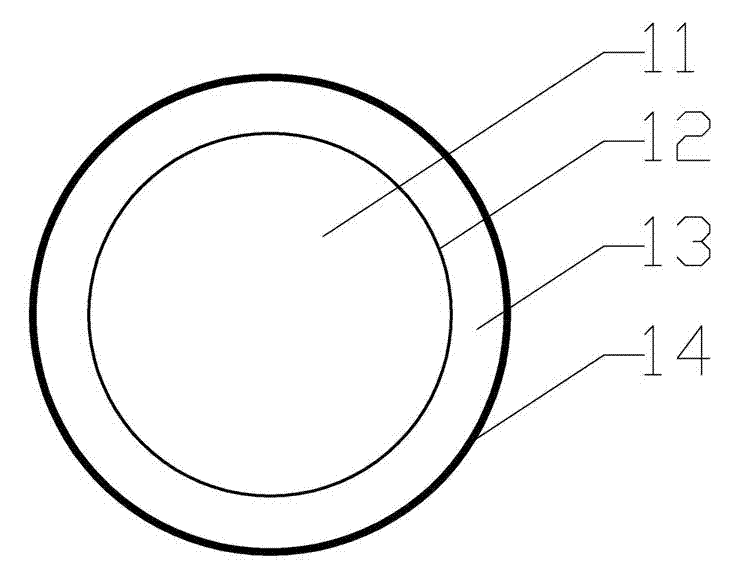

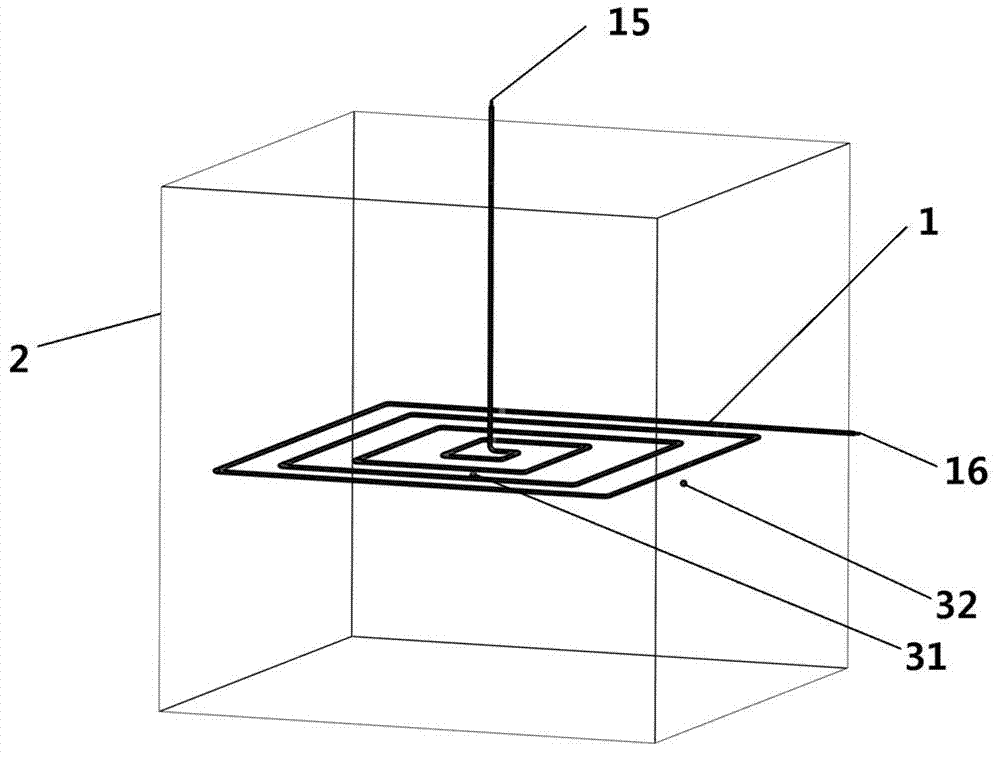

[0048] Make a cubic template 2 of 1m×1m×1m. The bottom surface of formwork 2 and its surroundings are insulated with 80mm-thick benzene board, and the surface is insulated with film + 100m...

Embodiment 2

[0064] Implementation steps and examples of the preparation of large-volume concrete, the production of concrete formwork, the insulation measures outside the formwork, the setting of temperature sensors, the flow rate of cooling water, the inlet water temperature of cooling water, and the cooling method of large-volume concrete in Example 2 1 is the same.

[0065] The difference between embodiment 2 and embodiment 1 is that the phase change material is changed into paraffin wax C 18 (solid-liquid phase change material, the phase transition temperature is 28°C) and paraffin C 16 -C 28 (Solid-liquid phase change material, the phase change temperature range is 42~44°C) The two are used in combination at a weight ratio of 8:2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Phase transition temperature | aaaaa | aaaaa |

| Phase transition temperature | aaaaa | aaaaa |

| Phase transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com