Aqueous dispersion and process for production thereof, and laminate

A technology for aqueous dispersion and manufacturing method, which is applied in layered products, chemical instruments and methods, coatings, etc., can solve the problem that ammonia cannot be obtained from aqueous dispersion, etc., and achieves excellent dispersibility, high uniformity, and water resistance. excellent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0043] Hereinafter, the aqueous dispersion of the present invention, its production method, and a laminate using the same will be described in detail. In addition, as long as there is no particular description for each embodiment such as the first embodiment of the present invention, the second embodiment of the present invention, etc., it is common among the three modes of the first embodiment to the third embodiment. items, explain.

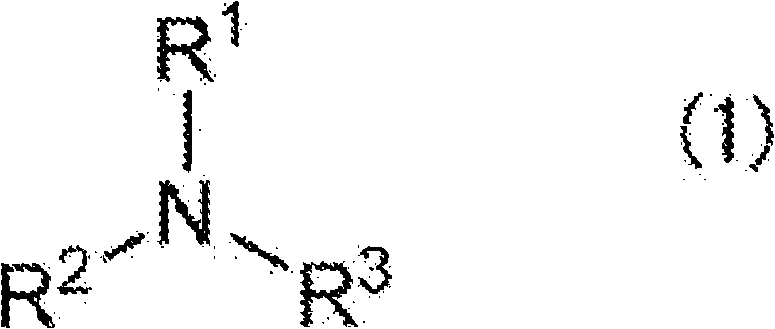

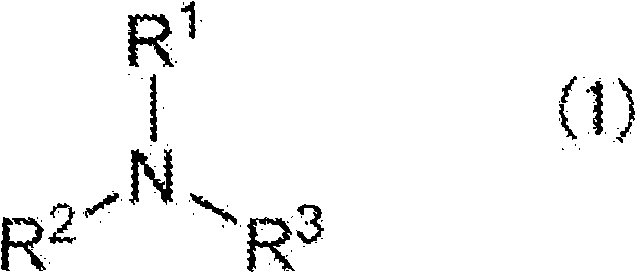

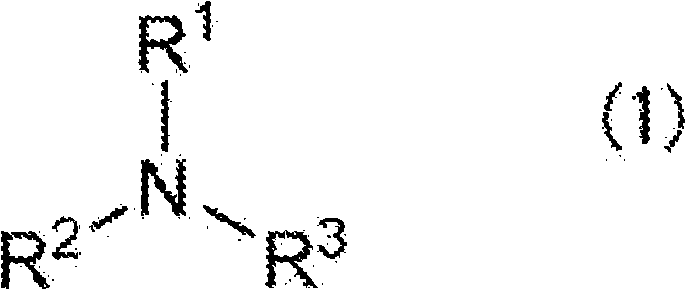

[0044] The method for producing an aqueous dispersion liquid according to the first embodiment of the present invention is constituted in that, in an aqueous medium, ethylene·( The meth)acrylic copolymer (A) is neutralized and dispersed.

[0045] The method for producing an aqueous dispersion according to the second embodiment of the present invention is constituted in that, in an aqueous medium, a structure derived from (meth)acrylic acid is added to an aqueous medium using alkanolamine (B) and ammonia (C). The ethylene·(meth)acrylic copolym...

Embodiment

[0139] Hereinafter, the present invention will be described more specifically using examples, but the present invention is not limited to the following examples unless the gist is exceeded. In addition, "ethylene content" shows the copolymerization ratio of the repeating structural unit derived from ethylene, and "(meth)acrylic acid content" shows the copolymerization ratio of the repeating structural unit derived from (meth)acrylic acid. In addition, MFR is a melt flow rate value measured at 190 degreeC and the load of 2160g based on JISK7210-1999.

Embodiment 101

[0142] Into a 300 ml autoclave, 64 g of ethylene-methacrylic acid copolymer (ethylene content: 80% by mass, methacrylic acid content: 20% by mass, MFR = 60 g / 10 minutes), 243 g of ion-exchanged water, and 13.1 g of diethylethanolamine were charged. , Stirring was performed for 1 hour at a temperature of 150° C. and a stirring speed of 1200 rpm. At this time, the degree of neutralization of alkanolamine (the number of moles of carboxyl groups in the ethylene / methacrylic acid-based copolymer, the ratio of alkanolamine) was 75 mol%. Then, it was slowly cooled with tap water at a cooling rate of 1° C. / minute to 3° C. / minute to obtain an aqueous dispersion. The solid content concentration of the obtained aqueous dispersion liquid was 20 mass %.

[0143] Next, the following evaluations were performed on the obtained aqueous dispersion liquid. The results of measurement and evaluation are shown in Table 1 below.

[0144] [1] Decentralization

[0145] The obtained aqueous dispersi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com